K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

Note

The electrical power supply and supply air pressure data

indicated on the name plate must be complied with during

commissioning.

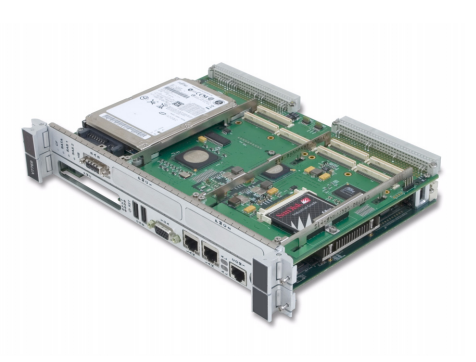

ABB 07KT97H3 Programmable Processor Unit

5 Installation

Pneumatic connections

Air supply

Instrument air*

Purity Maximum particle size: 5 μm

Maximum particle density: 5 mg/m3

Oil content Maximum concentration 1 mg/m3

Pressure dew point 10 K below operating temperature

Supply pressure** Standard design:

1.4 to 6 bar (20 to 90 psi)

Marine version:

1.6 to 5.5 bar (23 to 80 psi)

Air consumption*** < 0.03 kg/h / 0.015 scfm

* Free of oil, water and dust in accordance with DIN / ISO 8573-1. Pollution

and oil content in accordance with Class 3

** Do not exceed the maximum output pressure of the actuator

*** Independent of supply pressure

6 Commissioning

Note

The electrical power supply and supply air pressure data

indicated on the name plate must be complied with during

commissioning.

CAUTION

Risk of injury due to incorrect parameter values!

Incorrect parameter values can cause the valve to move

unexpectedly. This can lead to process failures and result in

injuries.

• Before recommissioning a positioner that was previously

in use at another location, always reset the device to its

factory settings.

• Never start automatic adjustment before restoring the

factory settings!

Note

Please observe the information in Operation on page 32 to

operate the device!

Commissioning the positioner:

1. Open the pneumatic power supply.

2. Power-up the electric power supply and feed in the setpoint

signal 4 to 20 mA.

3. Checking mechanical mounting:

• Press and hold MODE; in addition, press or until

operating mode 1.3 (manual adjustment in the measuring

range) is displayed. Release MODE.

• Press or to move the actuator into the mechanical

end position; check the end positions; rotational angle is

displayed in degrees; for high-speed mode, press or

simultaneously.

Recommended rotational angle range

Linear actuators −28 to 28°

Rotary actuators −57 to 57°

Minimum angle 25°

4. Perform standard automatic adjustment in accordance with

Standard automatic adjustment on page 29.

Commissioning of the positioner is now complete, and the

device is ready for operation.

Operating modes

Selection from the operating level

1. Press and hold down MODE.

2. Also press and release rapidly as often as required. The

selected operating mode is displayed.

3. Release MODE.

The position is displayed in % or as a rotation angle.

Operating mode Mode indicator Position indicator

1.0

Control mode* with

adaptation of the control

parameters M10906a M10906f

1.1

Control mode* without

adaptation of the control

parameters M10906b M10906g

1.2

Manual adjustment** in

the operating range.

Adjust*** using or M10906c M10906g

1.3

Manual adjustment** in

the measuring range.

Adjust*** using or M10906d M10906h

* Since self-optimization in operating mode 1.0 is subject to several factors

during control operation with adaptation, incorrect adjustments could

appear over an extended period.

** Positioning not active.

*** For high-speed mode, press and simultaneously.

Standard automatic adjustment

Note

Standard Auto Adjust does not always result in optimum control

conditions.

Standard automatic adjustment for linear actuators*

1. MODE Press and hold until ADJ_LIN is displayed.

2. MODE Press and hold until the countdown ends.

3. Release MODE; this starts Autoadjust.

Standard automatic adjustment for rotary actuators*

1. ENTER Press and hold until ADJ_ROT is displayed.

2. ENTER Press and hold until the countdown ends.

3. Release ENTER; this starts Autoadjust.

If Autoadjust is successful, the parameters will be stored

automatically and the positioner will revert to operating mode

1.1.

If an error occurs during Autoadjust, the process will be

terminated with an error message.

Perform the following steps if an error occurs:

1. Press and hold down operating button or for

approximately three seconds.

The unit will switch to the operating level, mode 1.3 (manual

adjustment within the measuring range).

2. Check mechanical mounting in accordance with Mechanical

mounting on page 13 and repeat the standard automatic

adjustment.

* The zero position is determined automatically and saved during standard

automatic adjustment, counter-clockwise (CTCLOCKW) for linear actuators

and clockwise (CLOCKW) for rotary actuators

6 Commissioning

Sample parameters

‘Change the zero position of the LCD display from clockwise

(CLOCKW) to counter-clockwise limit stop (CTCLOCKW)’

Initial situation: the positioner is in bus operation on the

operating level.

1. Switching to the configuration level:

• Press and hold down and simultaneously,

• additionally quickly press and release ENTER,

• Wait for the countdown to go from 3 to 0,

• Release and .

The following is now shown in the display:

M10906i

2. Switching to parameter group 3._:

• Press and hold down MODE and ENTER simultaneously,

• additionally quickly press and release 2×,

The following is now shown in the display:

M10906j

• Release MODE and ENTER.

The following is now shown in the display:

M10906k

3. Selecting parameter 3.2:

• Press and hold down MODE,

• additionally quickly press and release 2×,

The following is now shown in the display:

M10906l

— Release MODE.

4. Changing parameter settings:

• Quickly press and release to select CTCLOCKW.

5. Switching to parameter 3.3 (Return to operating level) and

saving the new settings:

• Press and hold down MODE,

• additionally quickly press and release 2×,

The following is now shown in the display:

M10906m

• Release MODE,

• Quickly press and release to select NV_SAVE,

• Press ENTER and hold down until the countdown goes

from 3 to 0.

The new parameter setting is saved and the positioner

automatically returns to the operating level. It continues in the

operating mode that was active prior to the configuration level

being called up.

Setting the option modules

Setting the mechanical position indication

1. Loosen the screws for the housing cover and remove it.

2. Rotate the position indicator on the shaft to the desired

position.

3. Attach the housing cover and screw it onto the housing.

Tighten the screws so that they are hand-tight.

4. Attach the symbol label to mark the minimum and maximum

valve positions on the housing cover.

Note

The labels are located on the inside of the housing cover.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923