K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

− Component obsolescence, new parts are no longer available

− Cost to replace parts is high

− Decreasing ability to repair parts

− Electrical remote communication links are susceptible to

noise; lightning strikes

− Difficult to troubleshoot remote I/O problems

− Link is slow; takes time for I/O points to update

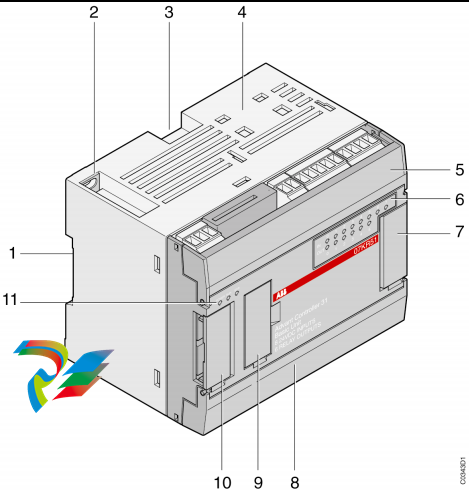

ABB 3BUS095373A Remote I/O module upgrade kit

− Component obsolescence, new parts are no longer available

− Cost to replace parts is high

− Decreasing ability to repair parts

− Electrical remote communication links are susceptible to

noise; lightning strikes

− Difficult to troubleshoot remote I/O problems

− Link is slow; takes time for I/O points to update

− Component obsolescence, new parts are no longer available

− Cost to replace parts is high

− Decreasing ability to repair parts

− Electrical remote communication links are susceptible to

noise; lightning strikes

− Difficult to troubleshoot remote I/O problems

− Link is slow; takes time for I/O points to update

− Controller configuration requires special “tuning” using

multiple segment control blocks

− Firmware compatibility issues between IMRIO02 and someI/O modules

− Must be careful when replacing parts in the systemBenefits

− Reliability; newer technology, improved fiber opticcommunications

− Availability of new replacement parts

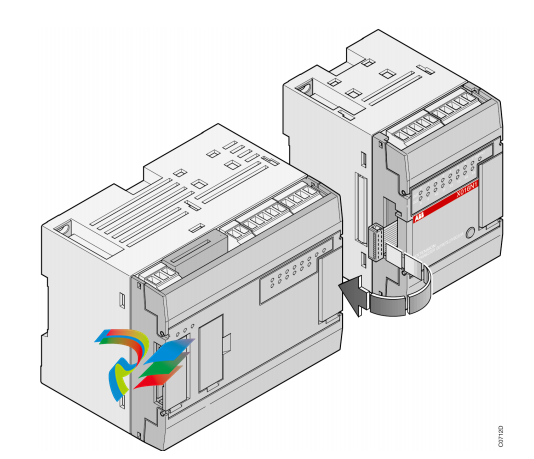

− Easy to replace the existing remote I/O setup – same rack

form factor; uses existing fiber optic cables; the RIO22

replaces the RIO02 in the Remote cabinet

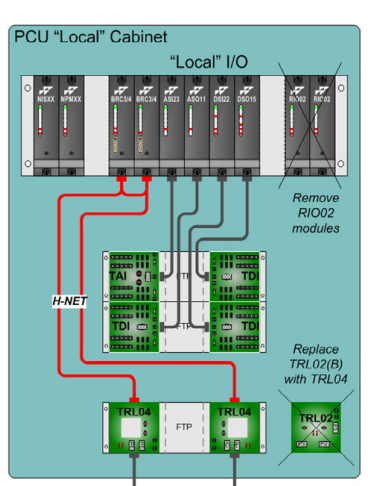

− Reduced cabinet footprint as the RIO02 in the Local cabinet

is no longer required; its functionality is now included in

a BRC300/400. The BRC replaces existing MFP or MFC

controllers in the Local cabinet

− Improved control performance - increased memory capacity,

faster execution and communication speeds

− Improved speed of communication link and remote I/Oupdates

− Improved hardware/firmware compatability between remote

I/O processor and remote I/O modules

− Easier firmware upgrades; IMRIO22 module has flashmemory

− Improved redundancy; faster detection/failover from primaryto backup IMRIO22

− Improved error-checking and diagnostics for troubleshooting

− Redundant HNET remote communication channels

Minimum System Requirements

− BRC300/400 controllers require Process Bus Adapters (PBA).

Please add these if they do not currently exist

− Composer Engineering Tools version 5.0 or later

− Fiber optic cable (62.5/125 micrometer multimode) for

remote link

Restrictions/Limitations

− Supports only fiber optic point-to-point communication links

− Electrical links (twin axial or coaxial cable) must be replaced

with fiber optic

− Serial or daisy chain multi-drop links are not supported;

multiple drops to remote cabinets (up to 6) now require a star

configuration from the Local cabinet

Remote I/O Module Upgrade Kit

− Part number INRIOK01 (for non-redundant configuration).

− Part number INRIOK02 (for redundant configuration).

Each kit includes the following components:

Component Quantities Part Number Description

INRIOK01 INRIOK02

1 2 IMRIO22 Harmony remote I/O module

1 2 PHCBRCPBA20000 Process bus adapter

4 4 NTRL04 HNET fiber optic repeater

termination unit

2 2 PMKHRMPBA1T004 Process bus adapter cable

for HNET

4 4 PHAMSCTER30000 HNET bus terminator

0 1 PMKHRMBRC3000A Bridge controller

redundancy cable

Note: Multi-drop remote I/O architectures will require inter-column connection cables for

daisy chaining additional termination units in a local cabinet.

Why ABB’s solution is bestP

System/Application Compatibility

The remote I/O functionality is compatible with all other existing

features of the Harmony BRC300/400 or later controllers. This

includes, but is not limited to, the following:

ABB Symphony Harmony/INFI 90 DCS

Remote I/O module upgrade kit

− Support for multiple remote I/O links

− Support mixed I/O types, e.g. IOR/S800, Harmony Rack I/O,

Harmony Block I/O

− Re-use of existing fiber optic remote link cables

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923