K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

The AC31 system consists of the series 30, 40, 50, and 90. This operating manual describes the series 40 and 50

ABB-AC31-40-Advant Controller

The AC31 system consists of the series 30. 40. 50. and 90. This operating manual describes the series 40 and 50. The AC31 brings accessibility to beginners and experienced automation users alike, for any application with 14 to approximately 1000 inputs / outputs and more, using the same set of basic components. From a compact machine fitted with a few automated functions to large installations spread over hundreds of meter, and even kilometers, the AC31 can fit your requirements. It is therefore possible to realize distributed applications throughout a site, a workshop, or a machine where each component (input / output units, basic unit) is close to the sensors / actuators. The whole setup is connected by a single twisted pair over which all information from the sensors is sent after processing by the basic unit to the actuators via the remote modules. Additional central units configured as slave can also be connected to this CS31 system bus. In case of the series 40 and 50 the following communication interfaces are available, to extend the AC31’s possibilities and integration with the company's other automation systems: MODBUS, ASCII, ARCNET, RCOM, AF100. The developments in this field are continual. Many users on all the continents have realized numerous applications such as: Machine control: - Manufacturing of floor boards - Assembly of electrical contactors - Manufacturing of ceramic products - Metallic pipe welding, etc. Controlling-commanding installations: - Wharf cranes - Water treatment - Ski lifts - Wind power machines, etc. System management: - Climatic anagement - Building power management - Tunnel ventilation - Alarms in hospital environments - Greenhouse lighting / humidity, etc.

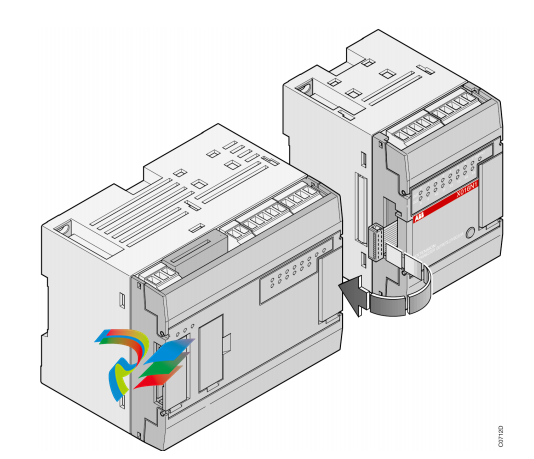

1.2 General set-up rules An ABB AC31 system always includes at least one AC31 basic unit. There are three types of basic units: - The 40 series basic unit, with a local interface for central inputs / outputs extensions - The 50 series basic unit, with a local interface for central inputs / outputs extensions and a CS31 system bus interface for decentralized extensions - The 90 series basic unit, with a CS31 system bus interface for decentralized extensions Each basic unit incorporates a specific number of digital inputs/outputs and in case of the series 90 occasionally analog inputs/outputs. It is possible, depending on the basic unit, to increase the number of inputs / outputs, to add input / output extensions connected directly to the basic units or remote input / output units via the CS31 twisted pair.

A master basic unit can manage up to 31 connection points, such as: - Series 50 remote units with central extension possibilities: a maximum of 6 extension units comprising of e. g. a maximum of 8 analog input channels and 8 analog output channels - Series 30 and 90 remote unit (without central extension possibilities) with analog or digital inputs / outputs - An ABB NCSA-01 variable speed drive interface - A high-speed counter unit - 30. 50 and 90 series basic units as slave with their own user program - Or any other device which supports CS31 communication. Comment: A connection point fitted solely with digital channels occupies 1 connection point. A connection point fitted with digital and analog channels occupies 2 connection points of the available 31. The maximum number of remote analog units depends on the MASTER basic unit: - 50 series: - a maximum of 31 remote analog input units or - a maximum of 31 remote analog output units or - a maximum of 15 central extensible remote units (ICMK 14 ..) with analog input/output extensions + 1 remote analog input/output unit (15 x 2 + 1 = 31) or - a mixed digital/analog configuration within the previous limits - 90 series: - a maximum of 12 remote analog input units or - a maximum of 12 remote analog output units or - a maximum of 12 central extensible remote units with analog extensions or - a mixed digital/analog configuration within the permissible limits

1.3 Power cuts or drops, battery The 40 and 50 series basic units provide an incorporated battery buffer in order to save the necessary information for the next startup should there be a power drop or cut. The buffer battery is an usual in the trade Vanadium Lithium accumulator. It is soldered on a printed-circuit board inside the unit and qualified personnel can exchange it by themselves. The accumulator is 100 % charged after 12 operating hours without interruption. Its lifetime is between 6 and 15 years; it depends on how often and how long the power supply of the unit is switched off. The battery buffer time is 20 days at 25 °C. During that time data (e.g. flags) can be stored with power supply of the unit switched off. The status word %IW 1062.15 (EW 62.15), Bit 3 gives information on the status of the battery (0 corresponds to error, 1 corresponds to OK). Caution: The following operating instructions are to be observed: • Never short-circuit or operate battery with the polarities reversed! They are likely to overheat and explode. Avoid chance short circuiting and therefore do not store batteries in metal containers and do not place them on metallic surfaces. Escaping lithium is health hazard. • Replace battery only with power supply on. Otherwise data may be lost. • Dispose of battery environmentally consciously! To save all or part of the data prior configuration of the basic unit is required (refer to volume 2 - System Technology). If the configuration of the basic unit is absent then all functions and internal data will be reset to 0 after power cut

Basic units 40 Series without CS31- system bus connection Central extensible basic units 07 CR 41. 24 V DC Central extensible basic unit, with 8 isolated inputs 24 V DC and 6 relay outputs 250 V AC / 2 A RS-232 interface for programming or ASCII or MODBUS communication 24 V DC power supply. 1SBP260020R1001 07 CR 41. 120/230 V AC Central extensible basic unit, with 8 isolated inputs 24 V DC and 6 relay outputs 250 V AC / 2 A RS-232 interface for programming or ASCII or MODBUS communication 24 V DC power supply output to power inputs 120 / 230 V AC power supply 1SBP260021R1001 07 CT 41. 24 V DC Central extensible basic unit, with 8 isolated inputs 24 V DC and 6 transistor outputs 24 V DC / 0.5 A RS-232 interface for programming or ASCII or MODBUS communication 24 V DC power supply 1SBP260022R1001 07 CR 42 - 24 V DC Extensible stand-alone basic unit, with 8 isolated inputs 24 V DC and 6 integrated relay outputs 250 V AC / 2 A and 3 analog inputs with 2 voltage inputs +/- 10 V RS-232 interface for programming oder ASCII or MODBUS communication, 24 V DC power supply 1SBP260023R1001 07 CR 42 - 120/230 V AC Extensible stand-alone basic unit, with 8 isolated inputs 24 V DC and 6 integrated relay outputs 250 V AC / 2 A and 3 analog inputs with 2 voltage inputs +/- 10 V RS-232 interface for programming oder ASCII or MODBUS communication, 24 V DC output for supplying the digital inputs 120 / 230 V AC power supply 1SBP260024R1001 07 CT 42 - 24 V DC Extensible stand-alone basic unit, with 8 isolated inputs 24 V DC and 6 integrated transistor outputs 24 V DC / 0.5 A and 3 analog inputs with 2 voltage inputs +/- 10 V RS-232 interface for programming oder ASCII or MODBUS communication, 24 V DC power supply 1SBP260025R1001

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923