K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

NextMove ESB-2 features the Mint motion control language. Mint is a structured form of

Basic, custom designed for stepper or servo motion control applications. It allows you to get

started very quickly with simple motion control programs. In addition, Mint includes a widerange of powerful commands for complex applications.

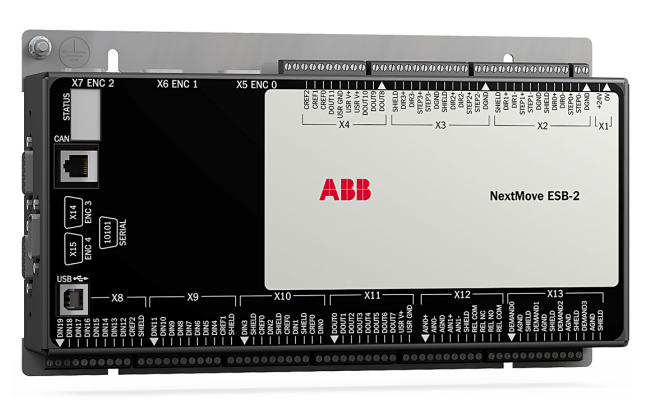

ABB NextMove ESB-2 motion controller

NextMove ESB-2 features

NextMove ESB-2 is a high performance multi-axis intelligent controller for servo and steppermotors.

NextMove ESB-2 features the Mint motion control language. Mint is a structured form of

Basic, custom designed for stepper or servo motion control applications. It allows you to get

started very quickly with simple motion control programs. In addition, Mint includes a wide

range of powerful commands for complex applications.

Standard features include:

Control of 4 stepper axes and either 3 or 4 servo axes (model dependent).

Additional encoder input for master follower applications.

A wide variety of motion types including point to point moves, software cams andgearing.

20 general purpose digital inputs, software configurable as level or edge triggered.

12 general purpose digital outputs.

2 differential analog inputs with 12-bit resolution.

4 single-ended analog outputs with 12-bit resolution.

USB 1.1 serial port (compatible with USB 2.0 and USB 3.0).

CANopen protocol for communication with Mint controllers and other third partyCANopen devices.

Programmable in Mint.

Drop-in replacement for NextMove ESB.

2.2 Receiving and inspection

When you receive your NextMove ESB-2, there are several things you should do

immediately:

1. Check the condition of the shipping container and report any damage immediately to the

carrier that delivered your NextMove ESB-2.

2. Remove the NextMove ESB-2 from the shipping container and remove all packing

material. The container and packing materials may be retained for future shipment.

3. Verify that the catalog number of the NextMove ESB-2 you received is the same as the

catalog number listed on your purchase order. The catalog number is described in the

next section.

4. Inspect the NextMove ESB-2 for external damage during shipment and report any

damage to the carrier that delivered your NextMove ESB-2.

5. If NextMove ESB-2 is to be stored for several weeks before use, be sure that it is stored

in a location that conforms to the storage humidity and temperature specifications shown

in section 7.1.11.

2.2.1 Identifying the catalog number

Different models of NextMove ESB-2 are available. As a reminder of which product has been

installed, it is a good idea to write the catalog number in the space provided below.

A description of the catalog numbers are show in the following table:

CatalognumberDescription SerialportStepperoutputtype

NSB202-501 3 servo axes, 4 stepper axes, 2 extra encoder inputs RS232 Differential

NSB202-502 3 servo axes, 4 stepper axes, 2 extra encoder inputs RS485

NSB203-501 3 servo axes, 4 stepper axes, 2 extra encoder inputs RS232 Open

collector NSB203-502 3 servo axes, 4 stepper axes, 2 extra encoder inputs RS485

NSB204-501 4 servo axes, 4 stepper axes, 1 extra encoder input RS232 Differential

NSB204-502 4 servo axes, 4 stepper axes, 1 extra encoder input RS485

NSB205-501 4 servo axes, 4 stepper axes, 1 extra encoder input RS232 Open

collector NSB205-502 4 servo axes, 4 stepper axes, 1 extra encoder input RS485

2.3 Units and abbreviations

The following units and abbreviations are used in this manual:

V. . . . . . . . . . . . . . . . Volt (also V AC and V DC)

W . . . . . . . . . . . . . . . Watt

A. . . . . . . . . . . . . . . . Ampere

Ω . . . . . . . . . . . . . . . Ohm

μF. . . . . . . . . . . . . . . microfarad

pF. . . . . . . . . . . . . . . picofarad

mH . . . . . . . . . . . . . . millihenry

Φ . . . . . . . . . . . . . . . phase

ms . . . . . . . . . . . . . . millisecond

μs . . . . . . . . . . . . . . . microsecond

ns . . . . . . . . . . . . . . . nanosecond

mm. . . . . . . . . . . . . . millimeter

m . . . . . . . . . . . . . . . meter

in . . . . . . . . . . . . . . . inch

ft. . . . . . . . . . . . . . . . feet

lbf-in . . . . . . . . . . . . . pound force inch (torque)

N·m . . . . . . . . . . . . . Newton meter (torque)

ADC . . . . . . . . . . . . . Analog to Digital Converter

ASCII . . . . . . . . . . . . American Standard Code for Information Interchange

AWG . . . . . . . . . . . . American Wire Gauge

CAL . . . . . . . . . . . . . CAN Application Layer

CAN . . . . . . . . . . . . . Controller Area Network

CDROM . . . . . . . . . . Compact Disc Read Only Memory

CiA . . . . . . . . . . . . . . CAN in Automation International Users and Manufacturers Group e.V.

CTRL+E . . . . . . . . . . on the PC keyboard, press Ctrl then E at the same time.

DAC . . . . . . . . . . . . . Digital to Analog Converter

DS301 . . . . . . . . . . . CiA CANopen Application Layer and Communication Profile

DS401 . . . . . . . . . . . CiA Device Profile for Generic I/O Devices

DS402 . . . . . . . . . . . CiA Device Profile for Drives and Motion Control

DS403 . . . . . . . . . . . CiA Device Profile for HMIs

EDS . . . . . . . . . . . . . Electronic Data Sheet

EMC. . . . . . . . . . . . . Electromagnetic Compatibility

HMI . . . . . . . . . . . . . Human Machine Interface

ISO. . . . . . . . . . . . . . International Standards Organization

Kbaud. . . . . . . . . . . . kilobaud (the same as Kbit/s in most applications)

LCD . . . . . . . . . . . . . Liquid Crystal Display

Mbps . . . . . . . . . . . . megabits/s

MB . . . . . . . . . . . . . . megabytes

MMC . . . . . . . . . . . . Mint Machine Center

(NC) . . . . . . . . . . . . . Not Connected

RF . . . . . . . . . . . . . . Radio Frequency

SSI . . . . . . . . . . . . . . Synchronous Serial Interface

TCP/IP . . . . . . . . . . . Transmission Control Protocol / Internet Protocol

UDP . . . . . . . . . . . . . User Datagram Protocol

3.1 Introduction

You should read all the sections in Basic Installation to ensure safe installation.

It is important that the correct steps are followed when installing the NextMove ESB-2. This

section describes the mechanical installation of the NextMove ESB-2.

3.1.1 Location requirements

You must read and understand this section before beginning the installation.

To prevent equipment damage, be certain that input and output signals are

powered and referenced correctly.

To ensure reliable performance of this equipment be certain that all signals to/

from the NextMove ESB-2 are shielded correctly.

Avoid locating the NextMove ESB-2 immediately above or beside heat

generating equipment, or directly below water steam pipes.

Avoid locating the NextMove ESB-2 in the vicinity of corrosive substances or

vapors, metal particles and dust.

The safe operation of this equipment depends upon its use in the appropriate environment.

The following points must be considered:

The NextMove ESB-2 is designed to be mounted indoors, permanently fixed andlocated.

The NextMove ESB-2 must be secured by the slots in the metal case.

The NextMove ESB-2 must be installed in an ambient temperature of 0 °C to 45 °C

(32 °F to 113 °F).

The NextMove ESB-2 must be installed in relative humidity levels of less than 80% for

temperatures up to 31 °C (87 °F) decreasing linearly to 50% relative humidity at 45 °C

(113 °F), non-condensing.

The NextMove ESB-2 must be installed where the pollution degree according to IEC

60664-1 shall not exceed 2.

There shall not be abnormal levels of nuclear radiation or X-rays.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923