K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Manufacturers

ABB

Model(s)

ABB Advant Controller 31, ABB Advant OCS

Estimated Shipping Size

Dimensions: 6.0" x 4.0" x 10.0"

(15.2 cm x 10.2 cm x 25.4 cm)

Weight: 1 lbs 8.0 oz (0.7kg )

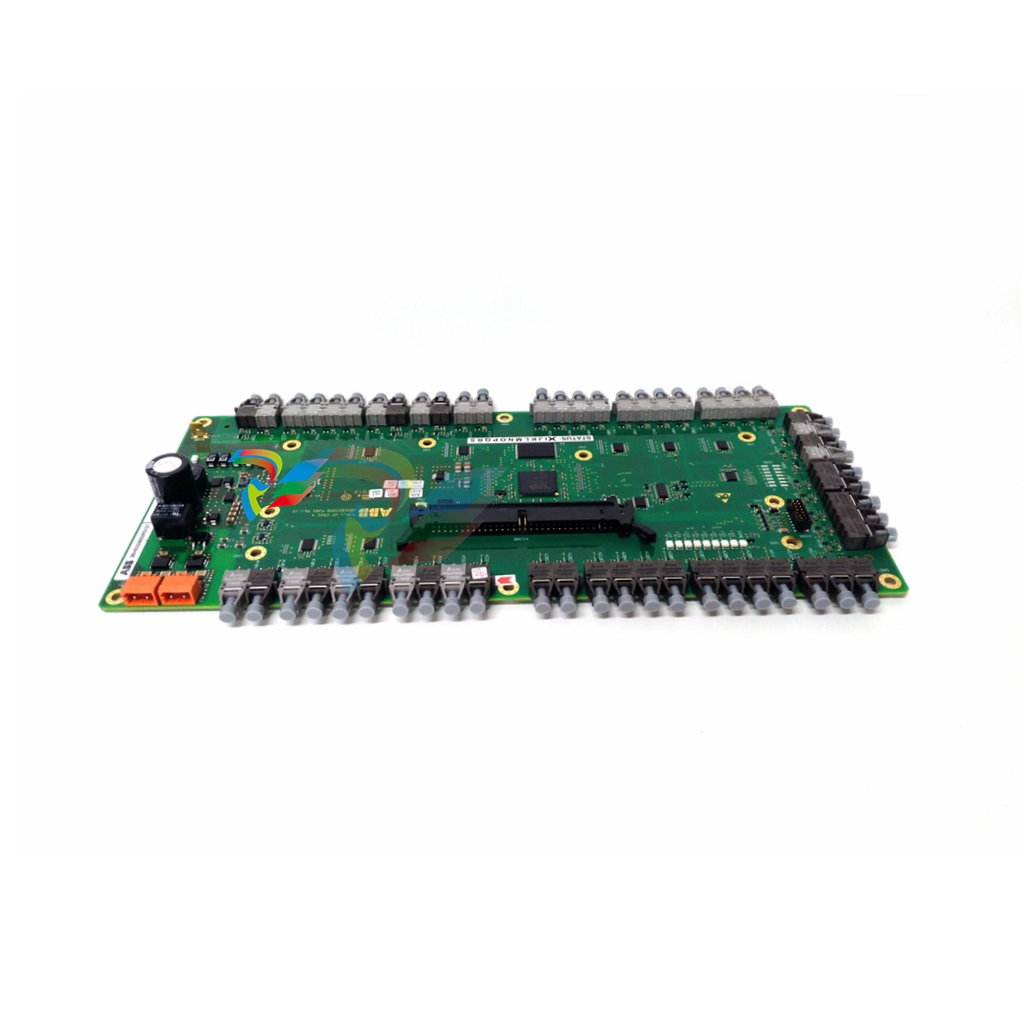

ABB GJR5250500R5101 RTU510 23KT92 Unit

Basic information

Model number and identification: ABB GJR5250500R5101 RTU510 23KT92 Unit, this model number represents the Remote Terminal Unit (RTU) of a specific ABB range. The ‘RTU510’ identifies its main function as remote data acquisition and control, and the ‘GJR5250500R5101’ and ‘23KT92’ are detailed model numbers for precise identification of the product. The ‘GJR5250500R5101’ and ‘23KT92’ are the detailed model numbers of the products, which are used to precisely identify the specifications and configuration of the products.

Manufacturing location information: ABB products are typically manufactured in multiple locations around the world, and this model may have been manufactured in one of ABB's major manufacturing locations, such as Sweden. Production facilities in Sweden have advanced manufacturing techniques and strict quality control systems to help ensure high quality and performance.

Dimensions and weight: The exact dimensions and weight are not yet known, but generally this type of equipment is designed according to its function and the environment in which it will be installed. Considering that it is an RTU for industrial automation and remote monitoring scenarios, it may be designed to be suitable for mounting in a control cabinet with a moderate weight for easy transport and installation.

Functional Features

Remote Data Acquisition

Multiple signal inputs: It is capable of receiving multiple types of input signals, both digital and analogue. For digital signals, it can be connected to devices such as limit switches, proximity switches, etc., to collect the status information of the devices (e.g. whether the devices are running or not, whether the door is closed or not, etc.); for analogue signals, it can be connected to temperature sensors, pressure sensors, liquid level sensors, etc., to collect the physical data of the site (e.g. the temperature value, the pressure value, the height of the liquid level, etc.). Through these signal inputs, it realises comprehensive monitoring of remote site equipment and environmental parameters.

High-precision Data Acquisition: It has high precision in acquiring analogue signals. It adopts advanced analogue-to-digital conversion technology, which can accurately convert the weak analogue signals coming from sensors into digital signals for subsequent transmission and processing. For example, for 0 - 10V analogue signals from temperature sensors, its analogue-to-digital conversion accuracy can reach 12 - 16 bits, which can accurately reflect small changes in temperature, thus providing more accurate data support for remote monitoring.

Remote Control Functions

Output signal control: An output signal channel is available for remote control of external devices. By outputting digital signals, it is possible to control the on/off of relays, contactors and other devices, and thus control the start/stop or state switching of motors, valves and other actuators. For example, in the remote control of the pumping station system, according to the water level and other parameters to control the pump motor start and stop, to achieve the remote operation of the field equipment.

Flexible control strategy: It supports a variety of control strategies and logic programming. Users can set different control rules according to the actual needs, through the configuration software or programming interface. For example, time-based control (e.g., starting/stopping equipment at regular intervals), event-based control (e.g., starting cooling equipment when the temperature exceeds the threshold), or complex sequential control (e.g., starting/stopping multiple devices in a certain order) can be realised, which improves the flexibility and degree of intelligence of controlling remote equipment.

Powerful Communication Functions

Multiple communication interfaces: Equipped with a variety of communication interfaces, such as RS-485, Ethernet interface, etc. RS-485 interface is suitable for long-distance, multi-point communication, can be connected to multiple on-site devices or communicate with other RTUs, the communication distance can be up to several kilometres, and anti-interference ability is strong; Ethernet interface is easy to connect to the internal network of the enterprise or the Internet, to achieve a wider range of remote monitoring and data transmission, support for standard network protocols (e.g. TCP/IP, TCP/IP, TCP/IP, TCP/IP, TCP/IP, TCP/IP). It supports standard network protocols (e.g. TCP/IP) and is capable of high-speed data interaction with remote monitoring centres, servers or cloud platforms.

Communication protocol support: Support a variety of industrial communication protocols, such as Modbus, DNP3 and so on. These protocols are widely used in the field of industrial automation and remote monitoring, enabling the RTU to communicate with devices and systems from different manufacturers. Through Modbus protocol, it can exchange data with a variety of Modbus-enabled sensors, PLCs (programmable logic controllers) and other devices; DNP3 protocol is widely used in remote terminal unit communication in power systems and other industries, ensuring communication compatibility and interoperability in different industry application scenarios.

Reliability and Safety

Fault detection and recovery: Built-in fault detection mechanism can monitor its own working status and the status of the communication link in real time. When there is signal abnormality, communication interruption, equipment failure, etc., it can detect and send fault alarm information to the monitoring centre in time. At the same time, it has certain automatic recovery capabilities, such as attempting to reconnect after a communication interruption, and continuing to work through redundant design or standby channels in the event of partial failure, in order to reduce system downtime due to failure.

Data security guarantee: Measures such as data encryption and secure authentication are adopted during data transmission. For example, SSL/TLS encryption protocol is supported for Ethernet communication to ensure the confidentiality and integrity of data during network transmission. Meanwhile, through the security authentication mechanism, only authorised users or devices can access and control the RTU, preventing illegal access and data tampering, and guaranteeing the security of the remote monitoring system.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923