K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

Operating range of rotary actuators:

The usable span is 90°, which must be entirely within the

measuring range, but does not necessarily need to run

symmetrically to the longitudinal axis.

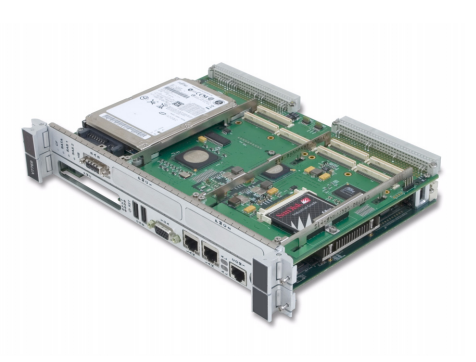

ABB 07EA90-SI Analog Input Unit

5 InstallationMechanical mounting

Operating range of rotary actuators:

The usable span is 90°, which must be entirely within the

measuring range, but does not necessarily need to run

symmetrically to the longitudinal axis. Note

During installation make sure that the actuator travel or rotation

angle for position feedback is implemented correctly.

Mounting on linear actuators

For mounting on a linear actuator in accordance with DIN / IEC

534 (lateral mounting as per NAMUR), the following attachment

kit is available:

M10413-01

1 Screw

2 Washer

3 Mounting bracket

4 Lever with follower pin

(for mechanical stroke

10 to 35 mm (0.39 to 1.38 in) or

20 to 100 mm (0.79 to 3.94 in)

5 Washers

6 Screws

7 U-bolts

8 Washers

9 Nuts

j Screws

k Spring washers

l Clamp plates

m Follower guide

Figure 6: Attachment kit

M10411-01

Figure 7: Attaching a follower guide to the actuator

1. Tighten the screws so that they are hand-tight.

2. Attach the follower guide 1 and clamp plates 2 with

screws 4 and spring washers 3 to the actuator stem.

M10409-01

Figure 8: Mounting lever and bracket on the positioner

1. Attach the lever 6 to the feedback shaft 5 of the

positioner (can only be mounted in one position due to the

cut shape of the feedback shaft).

2. Using the arrow marks 4, check whether the lever moves

within the operating range (between the arrows).

3. Hand-tighten the screw 7 on the lever.

4. Hold the prepared positioner (with the mount bracket 1 still

loose) on the actuator so that the follower pin for the lever

enters the follower guide to determine which tap holes on

the positioner must be used for the mount bracket.

5. Secure the mount bracket 1 with screws 2 and washers 3

using the relevant tap holes on the positioner housing.

Tighten the screws as evenly as possible to ensure

subsequent linearity. Align the mount bracket in the oblong

hole to ensure that the operating range is symmetrical (lever

moves between the arrow marks 4).

M10418-01 2 1 4 3

Figure 9: Mounting on a cast iron yoke

1. Attach the mount bracket 2 with screw 4 and washer 3

to the cast iron yoke 1.

or

M10419-01 2 1 3 5 4

Figure 10: Mounting on a columnar yoke

1. Hold the mount bracket 3 in the proper position on the

columnar yoke 2.

2. Insert the U-bolts 1 from the inside of the columnar yoke 2

through the holes of the mount bracket.

3. Add the washers 4 and nuts 5.

Tighten the nuts so that they are hand-tight.

Note

Adjust the height of the positioner on the cast iron yoke or

columnar yoke until the lever is horizontal (based on a visual

check) at half stroke of the valve.

M10420-01

2 1

1 Increase linkage 2 Decrease linkage

Figure 11: Positioner linkage

The scale on the lever indicates the link points for the various

stroke ranges of the valve.

Move the bolt with the follower pin in the oblong hole of the

lever to adjust the stroke range of the valve to the working range

for the position sensor.

Moving the link point inwards increases the rotation angle of the

sensor. Moving the link point outwards reduces the rotation

angle of the sensor.

Adjust the actuator stroke to make use of as large an angle of

rotation as possible (symmetrical around the center position) on

the position sensor.

Recommended range for linear actuators:

• −28 to 28°

Minimum angle:

• 25°

Note

After mounting, check whether the positioner is operating within

the measuring range.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923