K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

Position of actuator bolt

The actuator bolt for moving the potentiometer lever can be

mounted permanently on the lever itself or on the valve stem.

Depending on the mounting method, when the valve moves the

actuator bolt performs either a circular or a linear movement

with reference to the center of rotation of the potentiometer

lever. Select the chosen bolt position in the HMI menu in order to

ensure optimum linearization. The default setting is actuator

bolt on lever.

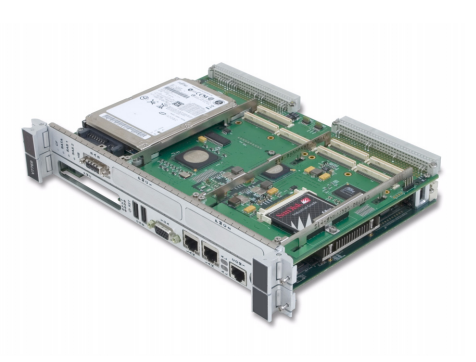

ABB 07KR31 FPR36000227R1202-S Programmable Processor Unit

5 Installation

Mechanical mounting

Position of actuator bolt

The actuator bolt for moving the potentiometer lever can be

mounted permanently on the lever itself or on the valve stem.

Depending on the mounting method, when the valve moves the

actuator bolt performs either a circular or a linear movement

with reference to the center of rotation of the potentiometer

lever. Select the chosen bolt position in the HMI menu in order to

ensure optimum linearization. The default setting is actuator

bolt on lever.

M11031

1 2 3

5 4

1 Potentiometer lever

2 Actuator bolts

3 Valve stem

4 Valve yoke

5 Positioner

Figure 12: Actuator bolts on the lever (rear view)

M11032

1 2 3

5 4

1 Potentiometer lever

2 Actuator bolts

3 Valve stem

4 Valve yoke

5 Positioner

Figure 13: Actuator bolts on the valve (rear view)

Mounting on rotary actuator

For mounting on part-turn actuators in accordance with

VDI / VDE 3845, the following attachment kit is available:

M10130-01

Figure 14: Components of attachment kit

• Adapter 1 with spring 5

• four M6 screws each 4, spring washers 3 and washers 2

to fasten the attachment bracket 6 to the positioner

• four M5 screws 7, Spring washers 8 and washers 9 to

fasten the attachment bracket to the actuator

Required tools:

• Wrench, size 8 / 10

• Allen key, size 3

Figure 15: Mounting the adapter on the positioner

1. Determine the mounting position

(parallel to actuator or at 90° angle)

2. Calculate the rotational direction of the actuator

(right or left).

3. Move the part-turn actuator into the home position.

4. Pre-adjust feedback shaft.

To make sure that the positioner runs within the operating

range (refer to General on page 13), the mounting position as

well as the basic position and rotation direction of the

actuator must be considered when determining the adapter

position on axis 1. For this purpose, the feedback shaft can

be adjusted manually so that the adapter 3 can be attached

in the correct position.

5. Place the adapter in the proper position on the feedback

shaft and fasten with threaded pins 2. One of the threaded

pins must be locked in place on the flat side of the feedback shaft.

M10421-01

1 Attachment bracket

Figure 16: Screwing the attachment bracket onto the positioner

M10416

Figure 17: Screwing the positioner onto the actuator Note

After mounting, check whether the operating range of the

actuator matches the measuring range of the positioner, refer to

General on page 13.

5 Installation

Electrical connections

Safety instructions

DANGER

Risk of explosion for devices with local communication

interface (LCI)

A local communication interface (LCI) may not be operated in

hazardous areas.

• Never use the local communication interface (LCI) on the

main board in a hazardous area!

WARNING

Risk of injury due to live parts!

When the housing is open, contact protection is not provided

and EMC protection is limited.

• Before opening the housing, switch off the power supply.

The electrical connection may only be established by authorized

specialist personnel.

Notices on electrical connection in this instruction must be

observed; otherwise, electric safety and the IP-rating may be

adversely affected.

Safe isolation of electric circuits which are dangerous if touched

is only guaranteed when the connected devices fulfill the

requirements of EN 61140 (basic requirements for secure

separation).

To ensure safe isolation, install supply lines so that they are

separate from electrical circuits which are dangerous if touched,

or implement additional isolation measures for them.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923