K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

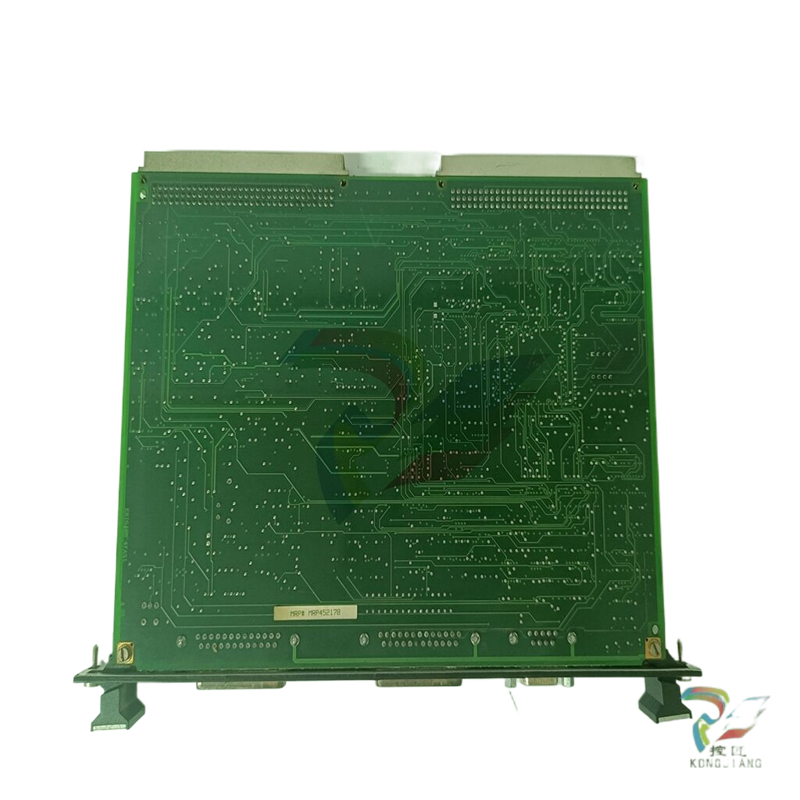

GE VMIVME-3125* Analog Input Board

GE VMIVME-3125* Analog Input Board

DESCRIPTION

The VMIVME-3125* Analog Input boards provide automatic scanning of 16 differential or 32 single-ended analog input channels. The channels are digitized with a 12-bit resolution Analog-to-Digital Converter (ADC). Each input is overvoltage protected and low-pass filtered. The board is very easy to use, no software setup is required. After powerup or system reset, the VMIVME-3125 automatically starts scanning each of its 16 or 32 input channels. Conversion data is stored automatically in a dual-port memory, making it immediately accessible from the VMEbus. The VMIVME-3125 provides on-board voltage references to perform an on-line or off-line built-in self-test. The input voltage range and gain are user-programmable with jumpers. The VMEbus base address and the access mode are fully selectable.

Features

Some of the distinguishing features of the VMIVME-3125 include:

• VMEbus 6U single height format

• 16 differential or 32 single-ended analog input channels

• One 12-bit A/D converter with built-in track-and-hold

• Automatic scanning of all inputs at 40 kHz aggregate rate

• No software initialization required to begin scanning

• Input ranges from ±50 mV to ±10 VDC

• Input overvoltage protection

• Analog inputs are low-pass filtered at 50 kHz

• Optional add on 40 Hz low-pass filter daughter board

• Discrete wire or mass terminated cables

• Input pull-down resistors prevent floating inputs

• Supports on-line and off-line Built-In-Test (BIT)

• Jumper programmable gains of x1, x10, x100

• Selectable A/D ranges of ±5 VDC, ±10 VDC and 0 to 10 VDC

• Data Accesses: D16, D08(EO), D08(O)

• Front panel LED

• 1,000 VDC isolation between analog and digital ground

• Optional 0 - 20, 4 - 20, and 5 - 25 mA current input ranges

Safety Summary

The following general safety precautions must be observed during all phases of the operation, service and repair of this product. Failure to comply with these precautions or with specific warnings elsewhere in this manual violates safety standards of design, manufacture and intended use of this product.

Ground the System

To minimize shock hazard, the chassis and system cabinet must be connected to an electrical ground. A three-conductor AC power cable should be used. The power cable must either be plugged into an approved three-contact electrical outlet or used with a three-contact to two-contact adapter with the grounding wire (green) firmly connected to an electrical ground (safety ground) at the power outlet.

Keep Away from Live Circuits

Operating personnel must not remove product covers. Component replacement and internal adjustments must be made by qualified maintenance personnel. Do not replace components with power cable connected. Under certain conditions, dangerous voltages may exist even with the power cable removed. To avoid injuries, always disconnect power and discharge circuits before touching them.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923