K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Manufacturers

ABB

Model(s)

ABB Advant Controller 31, ABB Advant OCS

Additional Information

32 inputs 24 VDC, Supply voltage 24 V DC, integrated CS31 bus connection

Estimated Shipping Size

Dimensions: 5.0" x 4.0" x 6.0"

(12.7 cm x 10.2 cm x 15.2 cm)

Weight: 0 lbs 12.0 oz (0.3kg )

Tariff Code: 8538907080

Country of Origin: Germany

Ships from Webster NY, USA

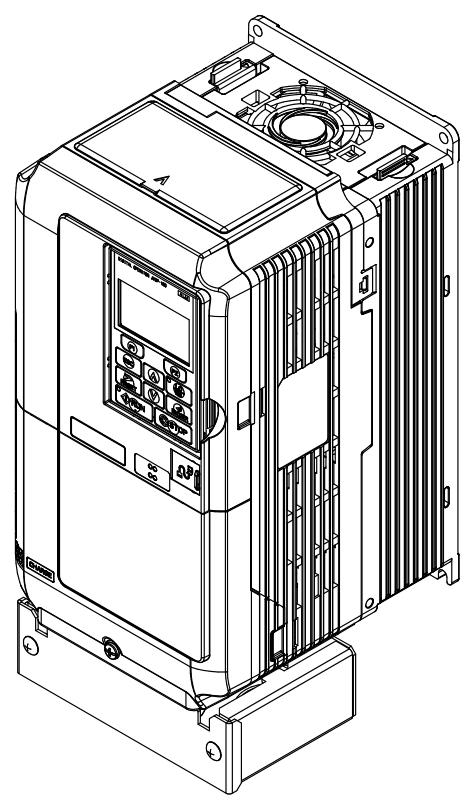

ABB GJR5252400R0101 Distributed Digital I/O Device

Product Overview

Model and Type: ABB GJR5252400R0101 is a distributed digital I/O device. In industrial automation systems, it plays a key role in connecting controllers (e.g. PLC or DCS system controllers) with external digital devices (e.g. sensors and actuators), and it is an important unit for realising signal inputs and outputs, as well as data interaction.

Distributed: ‘Distributed’ means that the device can be distributed in different locations on the industrial site, rather than being centralised in a control cabinet. This allows it to be closer to sensors and actuators, reducing signal transmission distances and interference, and optimising system wiring and architecture.

Performance features

Input and output functions

Digital Input Function: Equipped with multiple digital input channels for receiving digital signals from external digital devices (e.g. proximity switches, limit switches, pushbuttons, etc.). These digital input signals can be switching signals indicating the state of the device (e.g. device start/stop, door opening/closing status, etc.). Each digital input channel may have different electrical characteristics to accommodate various types of digital input devices, e.g., may support different voltage ranges (e.g., 5V, 12V, 24V, etc.) and signal types (e.g., PNP or NPN type signals).

Digital Output Function: Also has multiple digital output channels for sending control signals to external actuators (e.g. relays, indicators, solenoid valves, etc.). These digital output signals can be used to control the actions of the device, such as starting/stopping motors, lighting/extinguishing indicator lamps, and so on. The digital output channels can provide sufficient drive capability to ensure that common industrial actuators can be directly driven and may have short circuit protection, overload protection, etc. to improve the reliability of the equipment.

Communication function

Types of communication interfaces: A variety of communication interfaces are available for communicating with a host controller, such as a PLC or a master controller for a DCS. Common communication interfaces may include Ethernet interface, RS-485 interface, CAN bus interface and so on. Ethernet interface provides high-speed data transmission capability, which is suitable for long-distance communication and large amount of data transmission scenarios, and it is convenient to connect the equipment to the industrial Ethernet network to achieve remote monitoring and control; RS-485 interface is a commonly used interface for industrial field bus, which has the advantages of strong anti-jamming ability and long communication distance, and it can be used to build distributed control systems; CAN bus interface is used in the automotive industry and some industrial fields that have high real-time requirements. CAN bus interface is widely used in automotive industry and some industrial fields with high real-time requirements, supporting multi-master communication and highly reliable data transmission.

Communication protocol support: It supports a variety of industrial communication protocols, such as Modbus, Profibus - DP, Ethernet/IP and so on. Through these protocols, the distributed digital I/O device can seamlessly communicate with controllers produced by different manufacturers to achieve accurate data transmission and system integration. For example, the Modbus protocol can be used to easily communicate with many common industrial controllers for read and write operations.

Reliability and Stability

Hardware Reliability Measures: Manufactured with high-quality electronic components that undergo a rigorous screening and testing process to ensure that the equipment can operate stably for long periods of time in harsh industrial environments. For example, circuit boards may use multi-layer wiring and high-quality copper cladding process to improve anti-interference capability; electronic components (e.g., chips, capacitors, resistors, etc.) have high resistance to temperature changes, electromagnetic interference and mechanical vibration to reduce failures caused by environmental factors.

Fault diagnosis and recovery function: Built-in fault diagnosis function, it can monitor its own hardware status (such as input/output channel status, communication interface status, etc.) and software operation status in real time. When a fault is detected, it can issue an alarm signal in time (e.g., by flashing indicator lights, sending fault codes to the controller, etc.) and may have certain automatic recovery functions, such as automatically re-establishing the connection after certain recoverable faults (e.g., temporary interruption of communication) to reduce equipment downtime.

Scalability and Flexibility

Modular design (possible): a modular design is possible, allowing users to add or replace input and output modules according to actual needs. For example, if you need to add more digital input channels or digital output channels, you can do so by adding the corresponding modules without replacing the entire device. This modular design improves the scalability and flexibility of the device, and facilitates users to customise the configuration according to different industrial application scenarios.

Software Configuration Flexibility: Supporting software configuration, users can set the parameters of the device through special programming software or configuration tools, such as the functional definition of the input and output channels, communication parameter settings and so on. This software configuration flexibility allows the device to adapt to different control logics and industrial processes. For example, users can flexibly configure the correlation between digital input signals and digital output signals according to the requirements of the actual production process, so as to achieve a personalised control strategy.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|