K-WANG

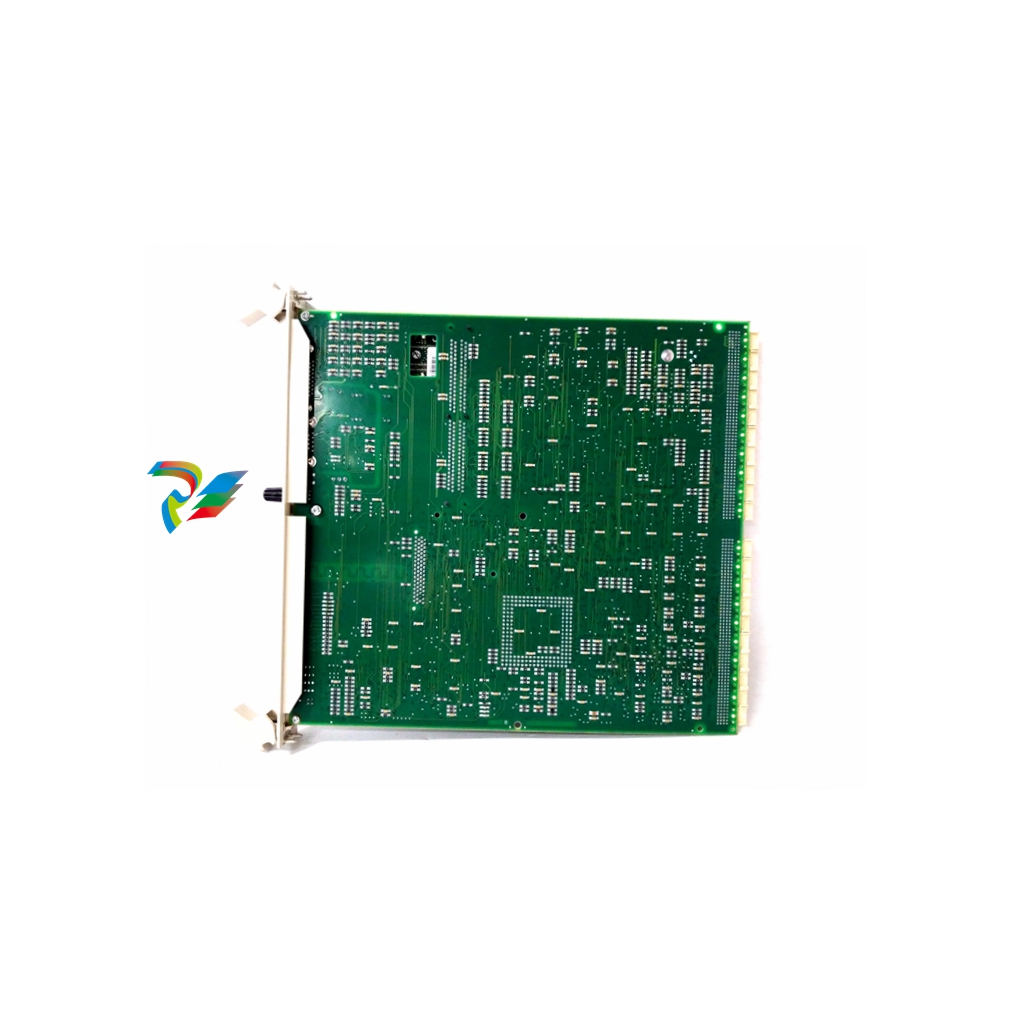

ABB Hard Disk Storage PMM 30 H&B Contronic

Basic introduction

The ABB Hard Disk Storage PMM 30 H&B Contronic is a hard disk storage device designed by ABB for the H&B Contronic system. It is mainly used in the system for storing and reading large amounts of data, providing support for stable system operation and data management.

Functional features

Powerful data storage

Large capacity storage: Compared with floppy disks and other storage devices, hard disk storage has a large capacity. It can store a large number of system files, program codes, data records and so on. For example, the capacity may range from tens of gigabytes to several terabytes, depending on the model and configuration of the hard disk. This high-capacity storage capability makes it possible to meet the demand for large amounts of data storage in H&B Contronic systems, such as storing complex automation control programs, long-term production data records, and so on.

Multiple Data Storage Format Support: It is capable of supporting a wide range of common data storage formats including, but not limited to, operating system file formats (e.g. NTFS, FAT32, etc.) as well as data formats used by specific industrial software. This makes it easy to interact with data from different software and systems, whether it is the configuration file of the storage system or the production data used for data analysis, all of which can be stored and managed flexibly.

Efficient data read and write performance

Fast data transfer rate: In terms of data reading and writing, hard disk storage devices have a high data transfer rate. Their internal use of high-speed rotating platters and sensitive head read/write technology enables fast data transfer. For example, internal data transfer rates of several hundred megabytes per second or more are possible, and data transfer rates on external interfaces (e.g., via the SATA interface) can also be high, depending on the version of the interface and the performance of the hard disk, to meet the system's need for fast access to data, such as rapid loading of a system program or the recording of large amounts of production data in real time.

Short seek time and latency: The seek time and latency of the drive are relatively short. Seek time is the time it takes for the head to move from one track to the target track, and latency includes things like waiting time for data to be read. With optimized motor control and head positioning technology, the PMM 30 hard disk storage can locate the data position that needs to be read or written in a short period of time, reducing the waiting time for data access and improving the overall operational efficiency of the system. For example, seek times can range from a few milliseconds to more than ten milliseconds, which is important for industrial control systems that access data frequently.

System Compatibility and Reliability

Deep compatibility with H&B Contronic systems: As a storage device designed specifically for this system, it is tightly integrated with the hardware and software environment of the H&B Contronic system. It is correctly recognized and configured by the system and can be optimized for the system's requirements. For example, the hard disk storage device can be automatically detected when the system starts up and the appropriate driver can be loaded, ensuring that the system can access the data in the hard disk for storage and reading without any problems.

High reliability design: A series of measures are adopted to ensure the reliability of stored data. The internal platters are specially treated to provide high resistance to wear and vibration. At the same time, the hard disk may also be equipped with a data error correction function, which, through redundant information and error correction algorithms, is able to correct errors in the data reading and writing process to a certain extent and prevent data loss. For example, in the industrial environment may encounter vibration, electromagnetic interference and other situations, hard disk storage devices can maintain data integrity and accessibility in these complex environments.

Technical Parameters

Physical Parameters

Size and form factor: The size and form factor of the drive conforms to common hard drive standards, such as 3.5-inch or 2.5-inch hard drive specifications. It is sized for easy installation in server chassis, industrial control cabinets, and other equipment. Size varies depending on the capacity of the drive and the purpose for which it is designed, with a typical 3.5-inch drive measuring approximately 147mm long, 101.6mm wide, and 26.1mm high, and a 2.5-inch drive being even smaller for ease of use in space-constrained equipment.

Weight: Weight varies depending on factors such as drive size and capacity, with 3.5-inch drives generally weighing around 0.5 - 1kg, and 2.5-inch drives weighing less, usually between 0.1 - 0.3kg. The lighter weight facilitates installation and mobility, especially in applications where weight is a factor, such as portable industrial equipment or storage devices mounted on mobile robots.

Electrical Parameters

Operating voltage and current: The operating voltage is generally between 5V and 12V DC, depending on the model and interface type of the hard disk. For example, a SATA-interface drive operates primarily at 5V and 12V and draws its power from the interface's power pins. The proper voltage and current supply ensures that the drive will operate reliably, but it also needs to be matched to the system's power supply to prevent power issues from causing damage to the drive.

Power Consumption: Power consumption is related to the operating state of the hard disk, which is relatively high during read and write operations and low during standby. For example, power consumption may range from a few watts to over a dozen watts during read and write operations, and around 1 - 2 watts in standby mode. Lower power consumption helps to reduce the overall energy consumption of the system and reduces the likelihood of the hard disk heating up during prolonged use, increasing the reliability of the device.

Performance Parameters

Capacity specifications: Capacity specifications are varied, ranging from relatively small tens of gigabytes (GB) to several terabytes (TB). Common capacities may include 500GB, 1TB, 2TB, etc. Users can choose according to their system's actual demand for storage capacity. Large-capacity hard disks can store more system files, applications and data records to meet the storage needs of industrial control systems of different sizes.

Rotation speed and cache size: For traditional mechanical hard disk, rotation speed is an important performance parameter. The rotation speed is generally between 5400rpm - 10000rpm. Higher rotation speed can increase the data transfer rate, but it may also increase the noise and power consumption. Cache size also affects the performance of the hard disk, the cache usually ranges from a few MB to several hundred MB, the cache can temporarily store frequently accessed data, reduce the time to read the data, and improve the overall performance of the hard disk.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923