K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

ABB H&B Contronic SS 41 Module SS 41 H&B Contronic

Basic Information

Appearance and structure:

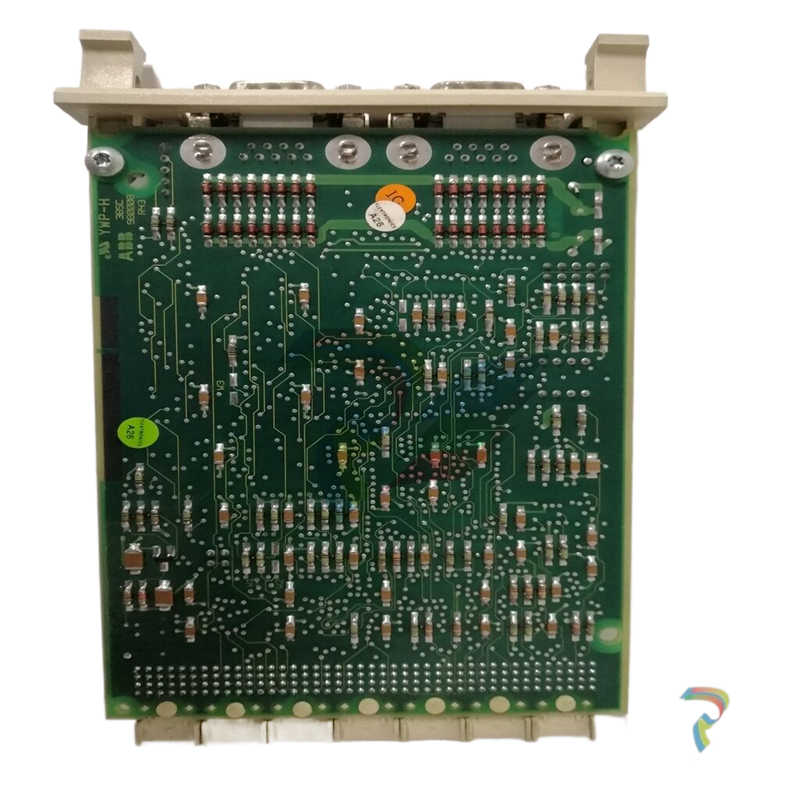

ABB H&B Contronic SS41 modules are usually presented in a rectangular shape. Their enclosures are made of robust materials such as metal or high quality engineering plastics, which provide good electromagnetic shielding, as well as resistance to corrosion, static electricity and dust for complex industrial environments. The colour of the module is generally industry standard grey or black.

On the surface of the module, there will be a clear marking with the words ‘SS41’ as well as ‘ABB H&B Contronic’ for easy identification and maintenance. The dimensions are designed to be compact, and may vary depending on the specific design and application scenario, but the overall small size makes it easy to install and layout in the limited space of a control cabinet or other industrial equipment.

Weight Information:

Although the specific weight is not explicitly given, but according to the characteristics of similar industrial modules, it is presumed that its weight is moderate, and will not bring an excessive burden to the installation and fixation.

Technical Parameters

Power requirements:

The module is generally powered by a voltage of about 24V DC (direct current). This power supply is more common in industrial environments, and it allows a certain range of voltage fluctuations, which is to adapt to the industrial site of the possible instability of the power supply, to ensure that the module in a certain degree of voltage changes can still work normally.

Input and output characteristics:

With multiple input and output channels, these include both digital and analogue types. Digital input channels can receive and process signals from various digital devices (such as digital sensors, switches, etc.), and has a strong anti-interference ability, can accurately identify signal changes to ensure the accuracy of the data. Analogue input channels receive continuously varying analogue signals such as temperature, pressure, flow, etc. These signals usually come from analogue sensors and the input range may cover common industry standard signal ranges such as 0 - 10V or 4 - 20mA. The output channels can output control signals to drive other devices such as motors, valves, etc. according to the internal control logic and the received input signals.

Communication Interface:

It supports a wide range of communication protocols, which is an important advantage in industrial automation systems. It may support communication protocols such as Profibus, Modbus, Industrial Ethernet, etc. Through these communication interfaces, the module can conveniently exchange data and communicate with other industrial equipments (such as PLC, host computer, other controllers, etc.) to achieve the collaborative work of the whole industrial automation system, real-time transmission and sharing of data, and improvement of production efficiency.

Functional features

Control Function:

SS41 module plays a key role in industrial control. It enables precise control of various devices and processes in the industrial production process. For example, for motors, it can control the start-stop and speed adjustment of motors; for valves, it can control the opening size of valves; for various industrial processes that require parameter adjustment, such as temperature control, pressure control, etc., it can output corresponding control signals according to input sensor signals through internal control logic and algorithms, so as to accurately regulate these parameters and realise automated production and process control.

Diagnostic and monitoring function:

A powerful diagnostic function is built-in, which can monitor its own working status and operating parameters in real time. It can monitor the power supply voltage to ensure normal power supply; monitor the working temperature to prevent the module from being damaged due to overheating; and monitor the communication status to ensure smooth data communication. Once any abnormal situation is found, such as voltage abnormality, high temperature, communication failure, etc., it can send the fault information to the host computer or other monitoring equipment through the communication interface in time, and send out an alarm signal, which is convenient for the maintenance personnel to locate and solve the problem quickly, and reduce the downtime and production loss caused by the equipment failure.

Application Fields

Power industry:

In places such as power plants and substations, the SS41 module can be used for generator set control and substation automation monitoring. For example, it can control the output power of generators, monitor the operation status of power equipment, and also participate in power distribution and management systems to ensure stable power supply and safe operation through precise control and monitoring.

Chemical Industry:

It has a wide range of applications in the chemical production process. For the chemical reactor, it can control the temperature and pressure of the reactor to ensure that the chemical reaction is carried out under suitable conditions; in the material transport link, it can control the flow of material transport to ensure the continuity and stability of the chemical production process; for the automated operation of chemical equipment, such as pumps, compressors, and other equipment control, it can also play an important role, which can help to improve the efficiency of the chemical production and the quality of the product. At the same time to protect the safety of the production process.

Pharmaceutical industry:

It can be applied to the automatic control of pharmaceutical production line. In the pharmaceutical packaging, filling, mixing and other links, it can control the operation of equipment to ensure the accuracy of the drug production process; at the same time, it can also be used for the monitoring of the production environment and data acquisition, such as monitoring the temperature of the clean room, humidity and other parameters, to ensure that the quality and consistency of the production of drugs.

Food and Beverage Industry:

In the production and processing of food and beverage, it can be used in the automation control of the production line, such as controlling the speed of the conveyor belt, the action of the packaging equipment, etc.; the control of the packaging equipment can ensure the accuracy and high efficiency of the food and beverage packaging; in the data collection of the quality inspection system, it can help to collect and transmit the relevant data, such as the weight of the product, the volume of the product, and other information, so as to improve the efficiency of the production and the quality of the product, to Guarantee food safety.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923