K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

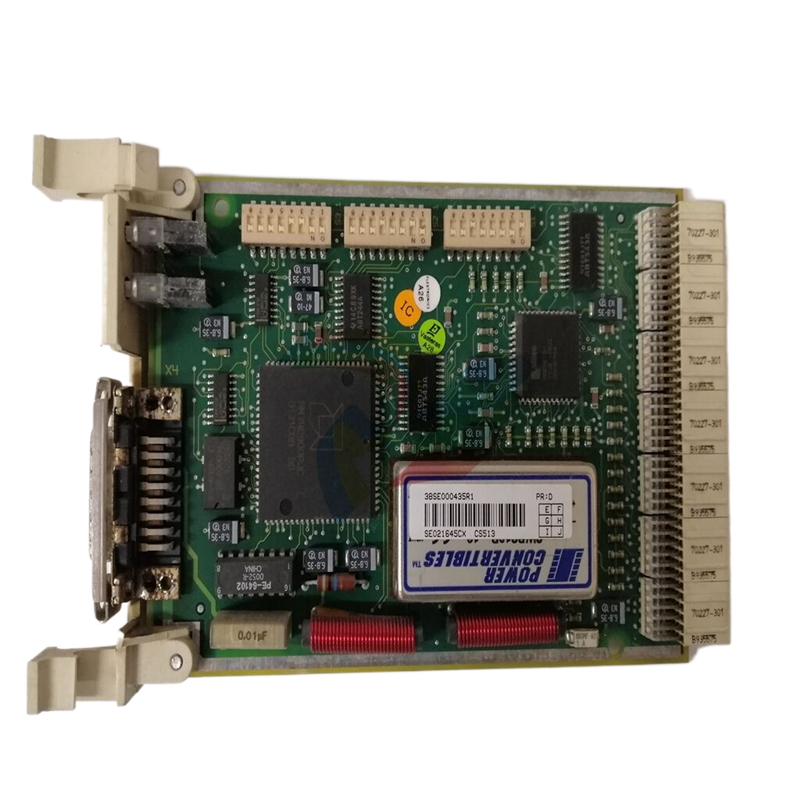

ABB 24h Testing Setup Unit SUE2 H&B Contronic

Basic Information

Appearance and dimensions: It has compact dimensions of approximately 3.0 inches × 5.0 inches × 7.0 inches (7.6cm x 12.7cm x 17.8cm) and weighs approximately 1 lb 3.0 oz (0.5kg).

Marking and model number: The ‘SUE2’ and ‘ABB H&B Contronic’ logos are clearly printed on the unit, making it easy to quickly identify it in a crowd of devices.

Functional features

Test function: As a 24-hour test setup unit, it can run test tasks continuously for a long time, and can conduct comprehensive and in-depth tests on ABB-related equipment or systems, including hardware performance tests, software function tests, communication link tests, etc., so as to ensure the stability and reliability of the equipment or system in the course of long-time operation.

Data Recording and Analysis: With the data recording function, it can record all kinds of data in the test process in real time, such as test time, test results, equipment operation status parameters, etc. At the same time, it can record the data of the equipment or system in real time. At the same time, the recorded data can be analysed and processed to generate a detailed test report, which provides a basis for equipment optimisation and fault diagnosis.

Alarm and monitoring function: During the test process, it can monitor the running status of the equipment or system in real time, and once abnormal conditions are found, such as equipment failure, parameter exceeding the standard, etc., it can send out alarm signals in time to remind the staff to take corresponding measures.

Technical parameters

Power Requirements: Usually work under a specific DC voltage, may be similar to other ABB H&B Contronic modules, around 24V DC, allowing a certain range of voltage fluctuations to adapt to the instability of power supply in industrial sites.

Communication interfaces: support a variety of common industrial communication protocols, such as Profibus, Modbus, Industrial Ethernet, etc., so that it can conveniently communicate and interact with other ABB devices and third-party devices, to achieve system integration and collaborative work.

Application areas

Industrial automated production line: In automated production lines such as automobile manufacturing, electronic equipment production, etc., it can be used to test and monitor the production equipment and control system 24 hours a day to ensure the stable operation of the production line, and improve the production efficiency and product quality.

Power system: in power plants, substations and other places, it can be used to test and maintain power equipment and automation control systems to ensure the safe and reliable operation of the power system. For example, the control system of the generator set, the automation monitoring system of the substation, etc. for a long time performance testing and fault diagnosis.

Intelligent building systems: In the automation control systems of intelligent buildings, such as HVAC systems, lift control systems, lighting control systems, etc., it can be used to test and optimise the equipment and control logic of the system, and to improve the building's energy use efficiency and comfort.

Our Main Brands

· - ABB Advant-800xA,Advant OCS,Bailey Infi 90 and Net 90,H&B Freelance 2000,DSQC Robots,IGCT / IGBT

· - GE General Electric Field Control, Genius I/O, QuickPanel, RX3i PacSystem, Series 90, Series 90, Series VersaMax

· - Allen Bradley Allen-Bradley SLC500, MicroLogix, CompactLogix, ControlLogix, PLC-5, Panel View,

· - Bently Nevada 3300 System, 3500 System

· - Honeywell 7800 Series, FSC, IPC, Mxopen, TDC 2000, TDC 3000, Experion PKS(C200,C300)

· - Yokogawa Centum CS - Centum VP, Centum XL - micro XL, FA-M3, ProSafe-PLC

· - Ovation, Foxboro, EPRO, Emerson DeltaV, Fuji, Siemens, HIMA, Prosoft, Invensys Triconex, ICS TRIPLEX, Woodward, Bachmann, Schneider

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923