K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

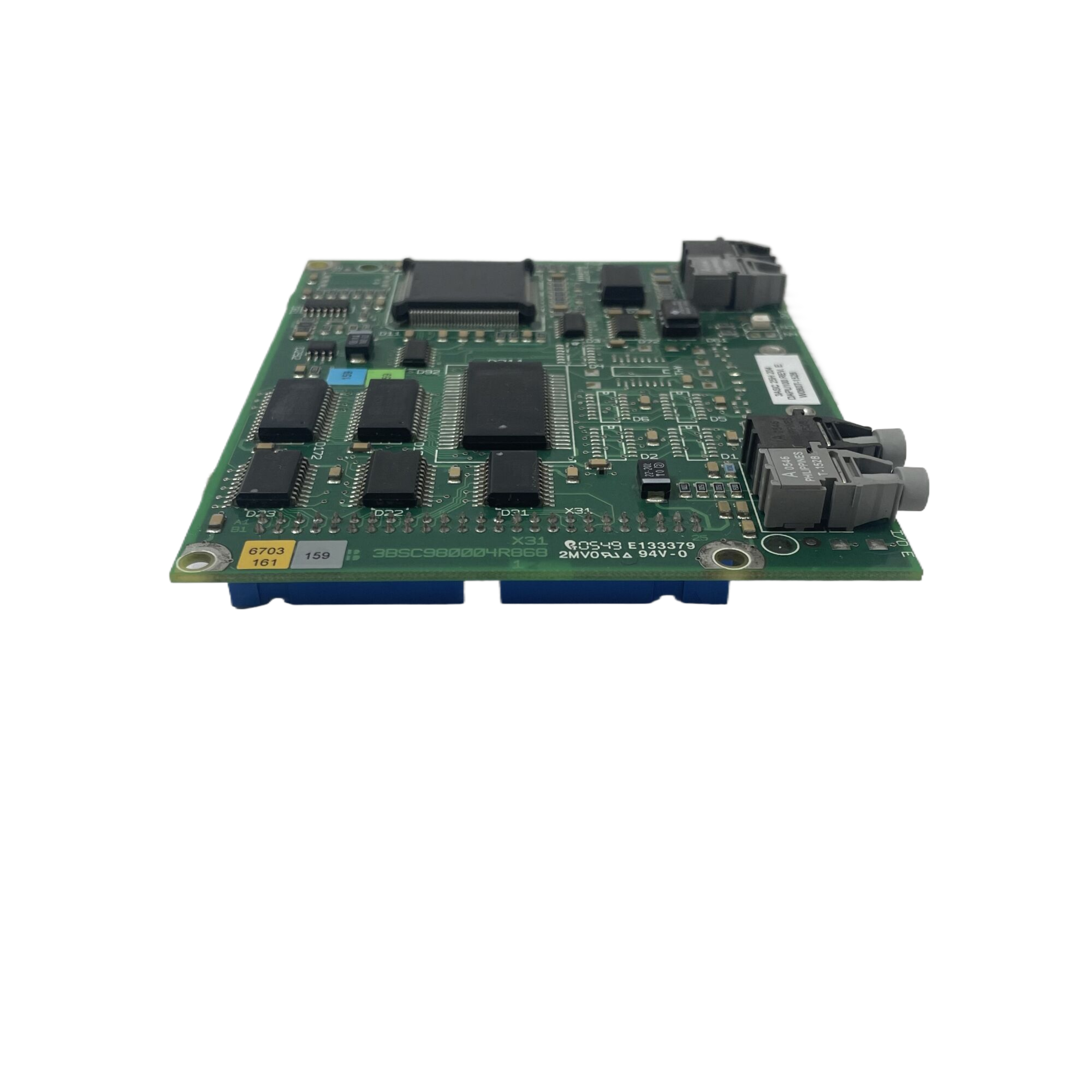

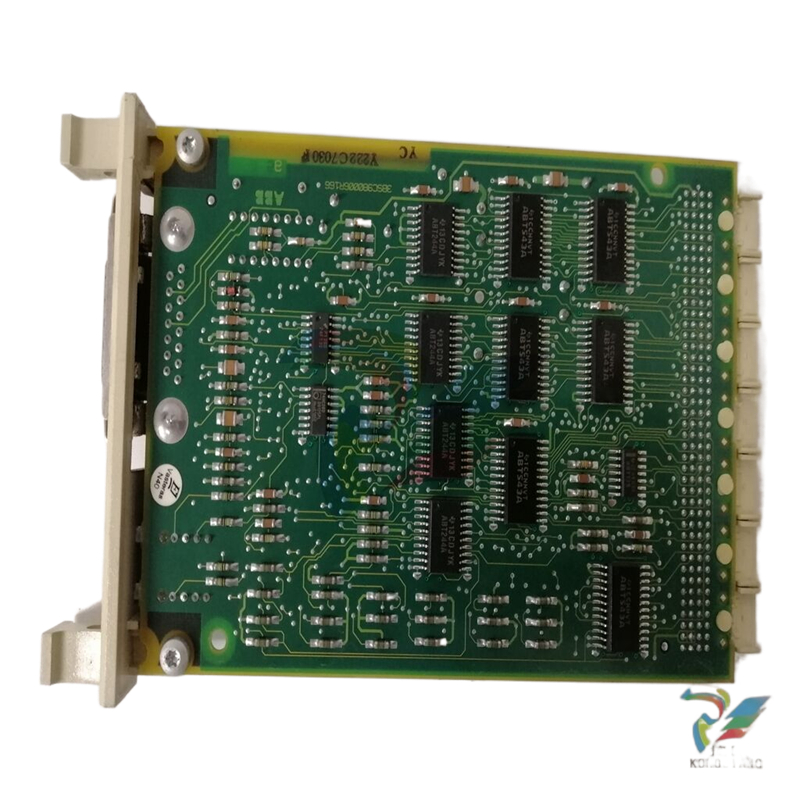

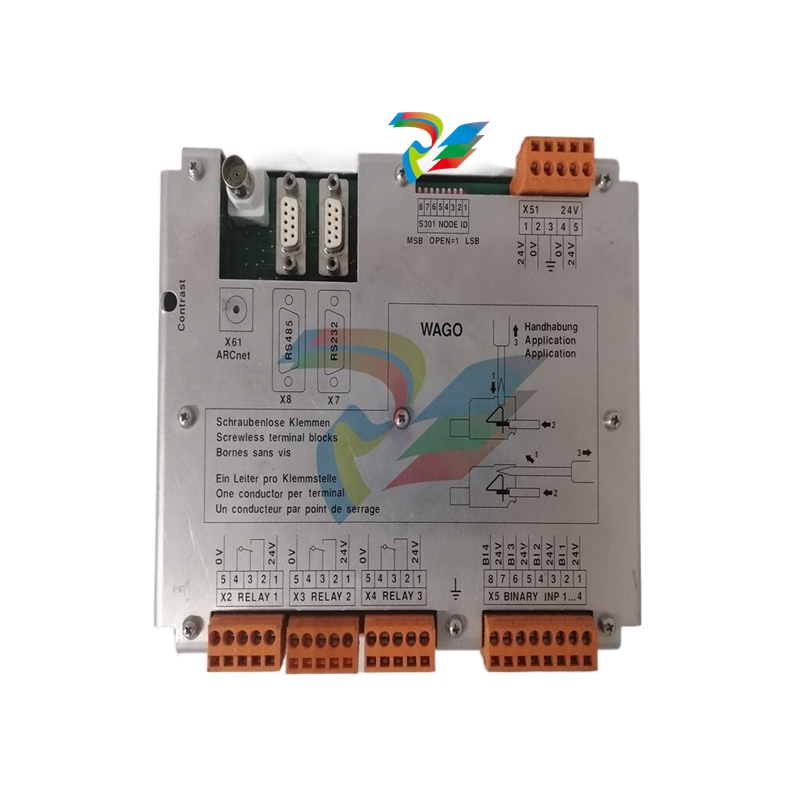

HIMatrix controllers are available for the programming tools SILworX and ELOP II Factory. Which programming tool can be used, depends on the processor operating system of the HIMatrix controller, refer to the following table

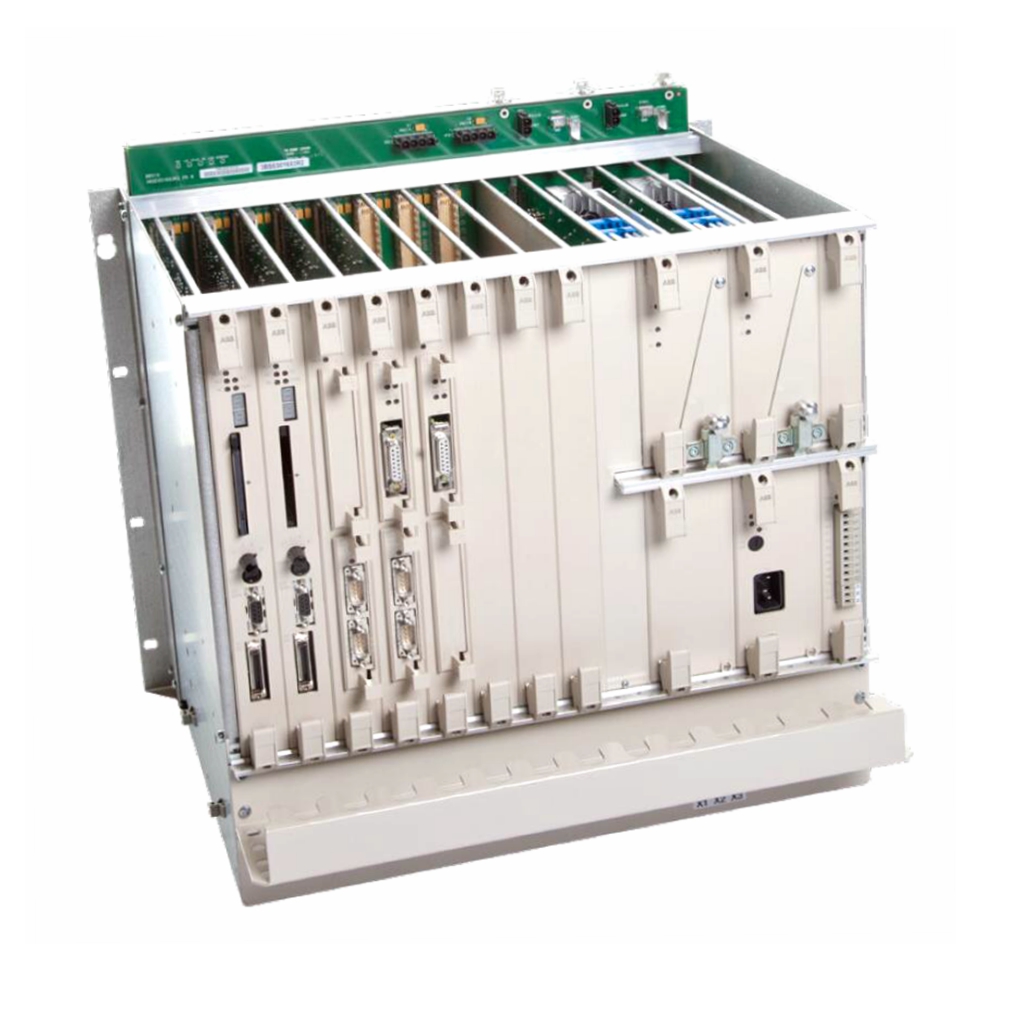

HIMA F3501 Safety-Related Controller

Safety

All safety information, notes and instructions specified in this document must be strictly

observed. The product may only be used if all guidelines and safety instructions are adhered to.

This product is operated with SELV or PELV. No imminent risk results from the product itself.

The use in Ex-Zone is permitted if additional measures are taken.

2.1 Intended Use

HIMatrix components are designed for assembling safety-related controller systems.

When using the components in the HIMatrix system, comply with the following general

requirements.

2.1.1 Environmental Requirements

Requirement type Range of values 1)

Protection class Protection class III in accordance with IEC/EN 61131-2

Ambient temperature 0...+60 °C

Storage temperature -40...+85 °C

Pollution Pollution degree II in accordance with IEC/EN 61131-2

Altitude < 2000 m

Housing Standard: IP20

Supply voltage 24 VDC

1) The values specified in the technical data apply and are decisive for devices with extended

environmental requirements.

Table 3: Environmental Requirements

Exposing the HIMatrix system to environmental conditions other than those specified in this

manual can cause the HIMatrix system to malfunction.

2.1.2 ESD Protective Measures

Only personnel with knowledge of ESD protective measures may modify or extend the system

or replace devices.

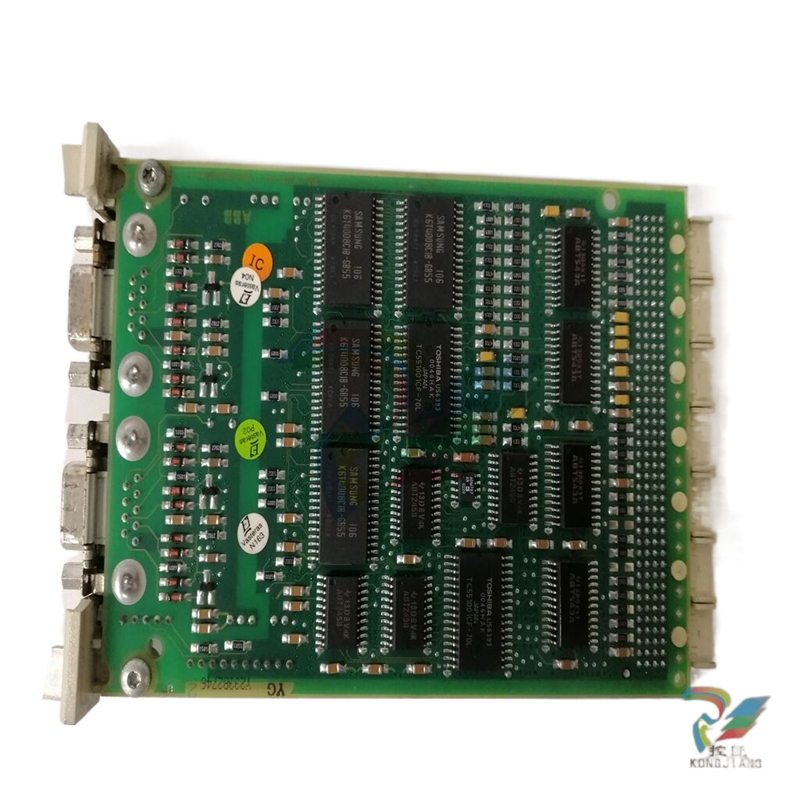

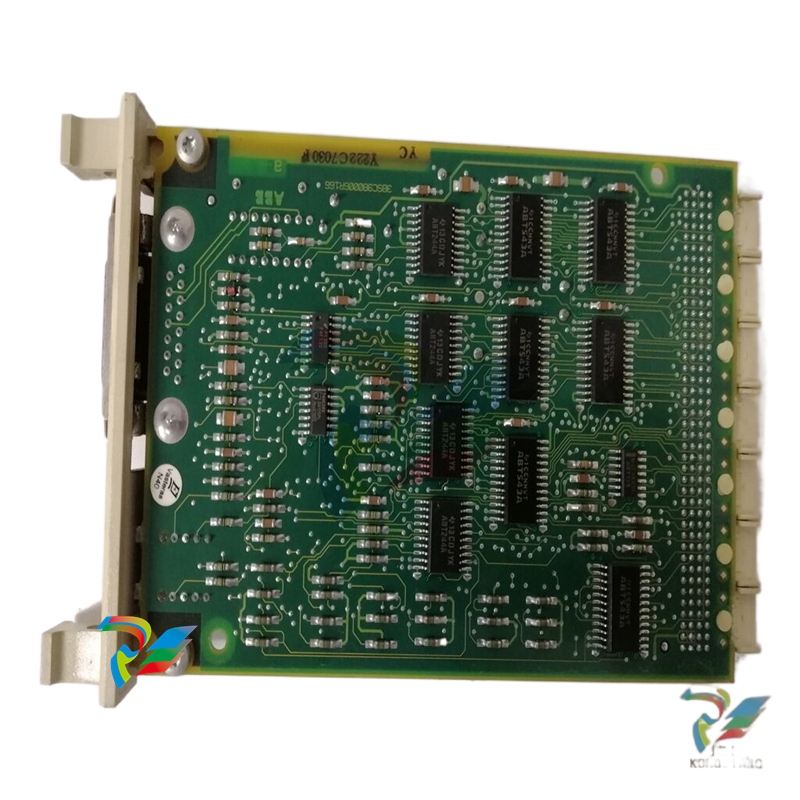

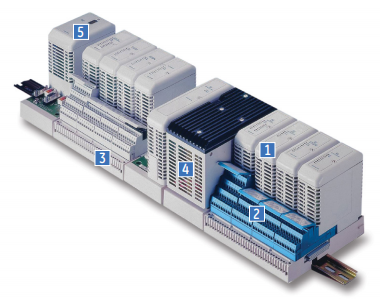

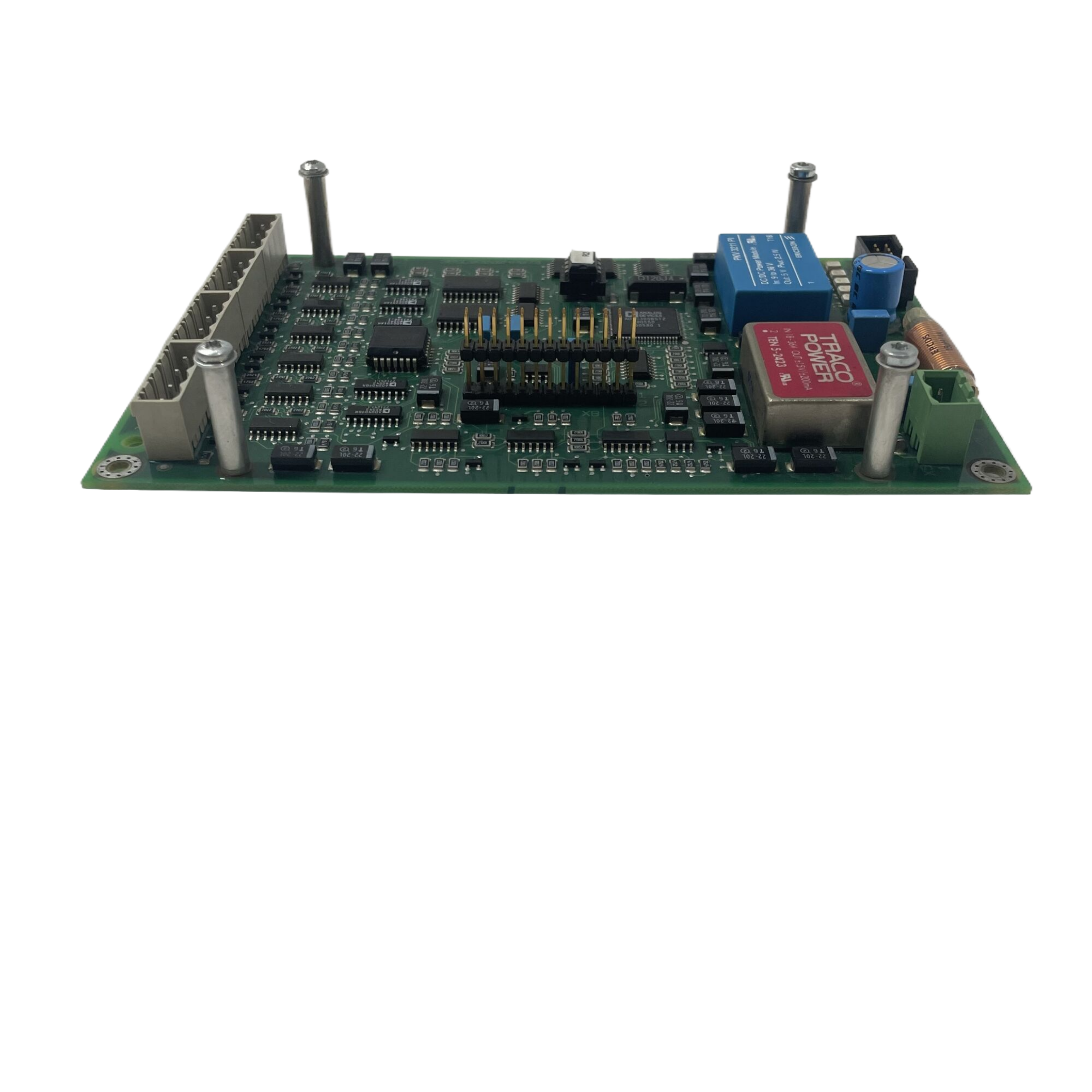

Product Description

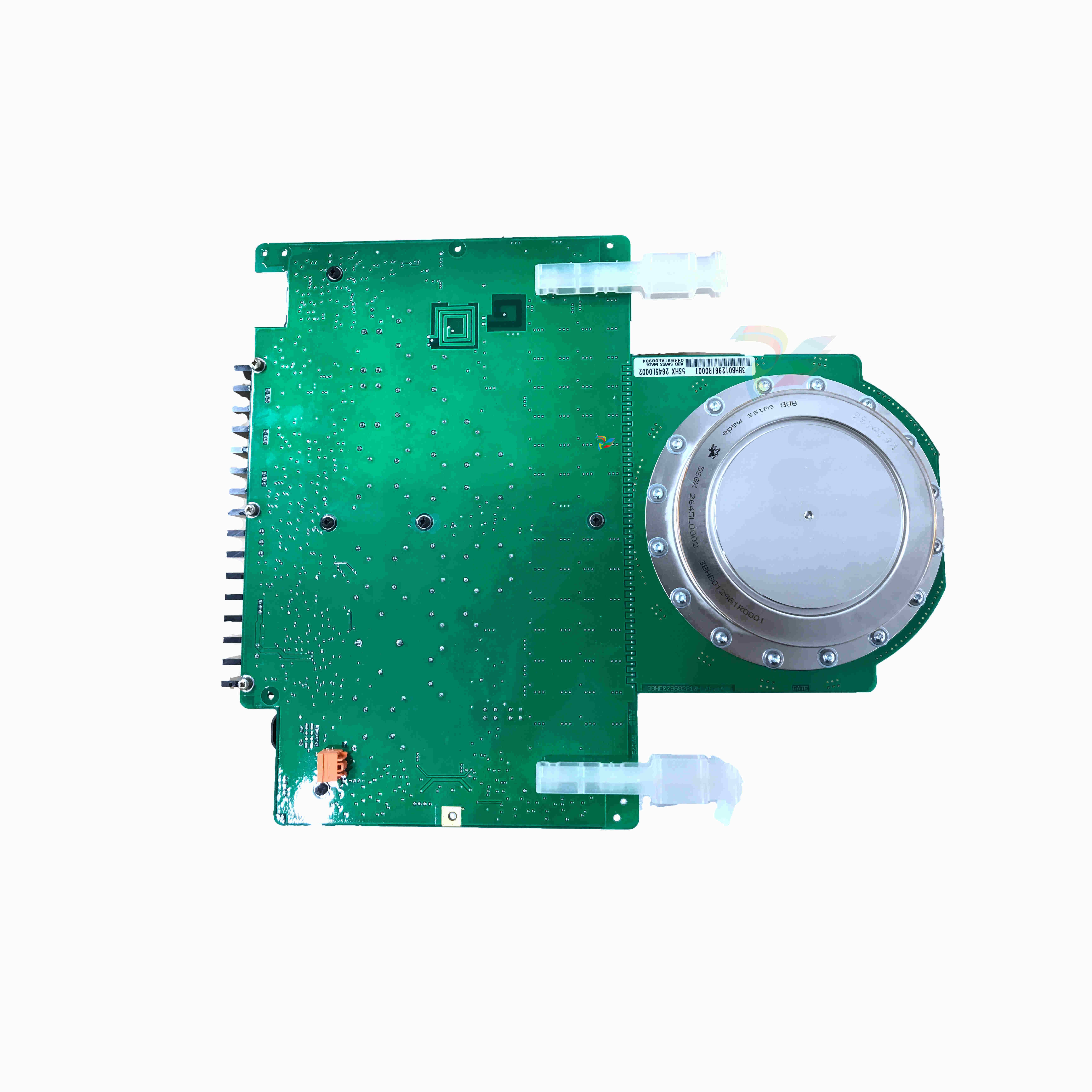

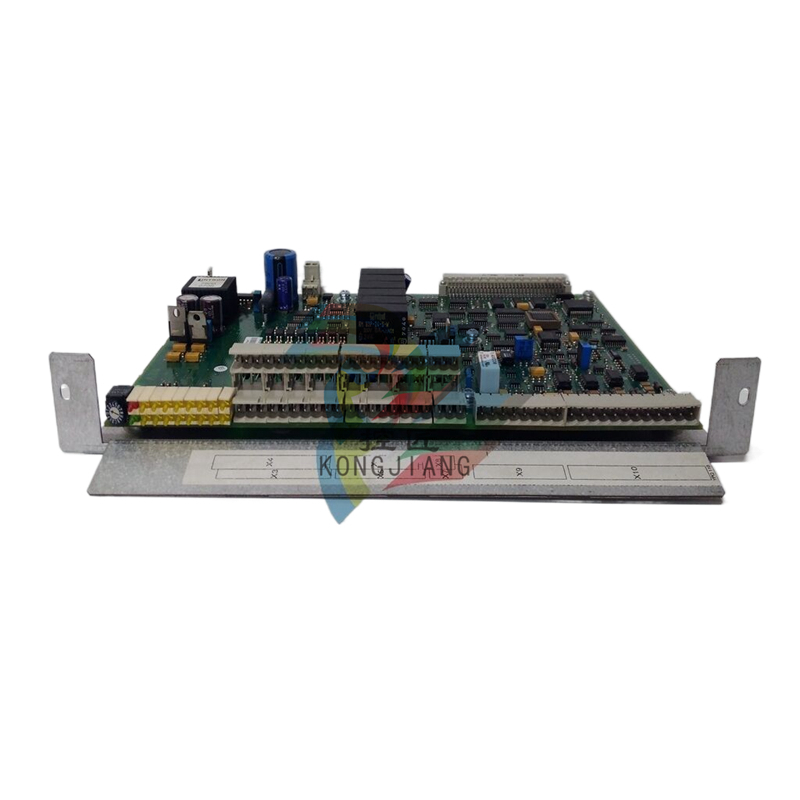

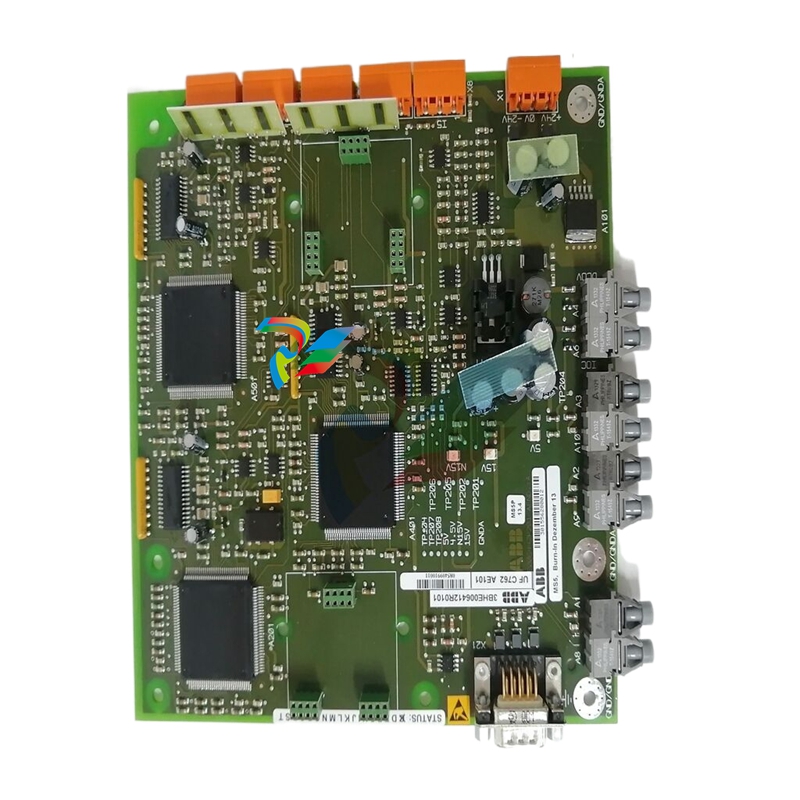

The safety-related F35 controller is a compact system in a metal housing with 24 digital inputs,

8 digital outputs, 2 counters and 8 analog inputs.

The controller is available in various model variants for SILworX and ELOP II Factory, see

Table 6.

The device is suitable for mounting in Ex-zone 2. see Chapter 4.1.6.

The device is TÜV-certified for safety-related applications up to SIL 3 (IEC 61508. IEC 61511

and IEC 62061), Cat. 4 and PL e (EN ISO 13849-1) and SIL 4 (EN 50126. EN 50128 and

EN 50129).

Further safety standards, application standards and test standards are specified in the

certificates available on the HIMA website.

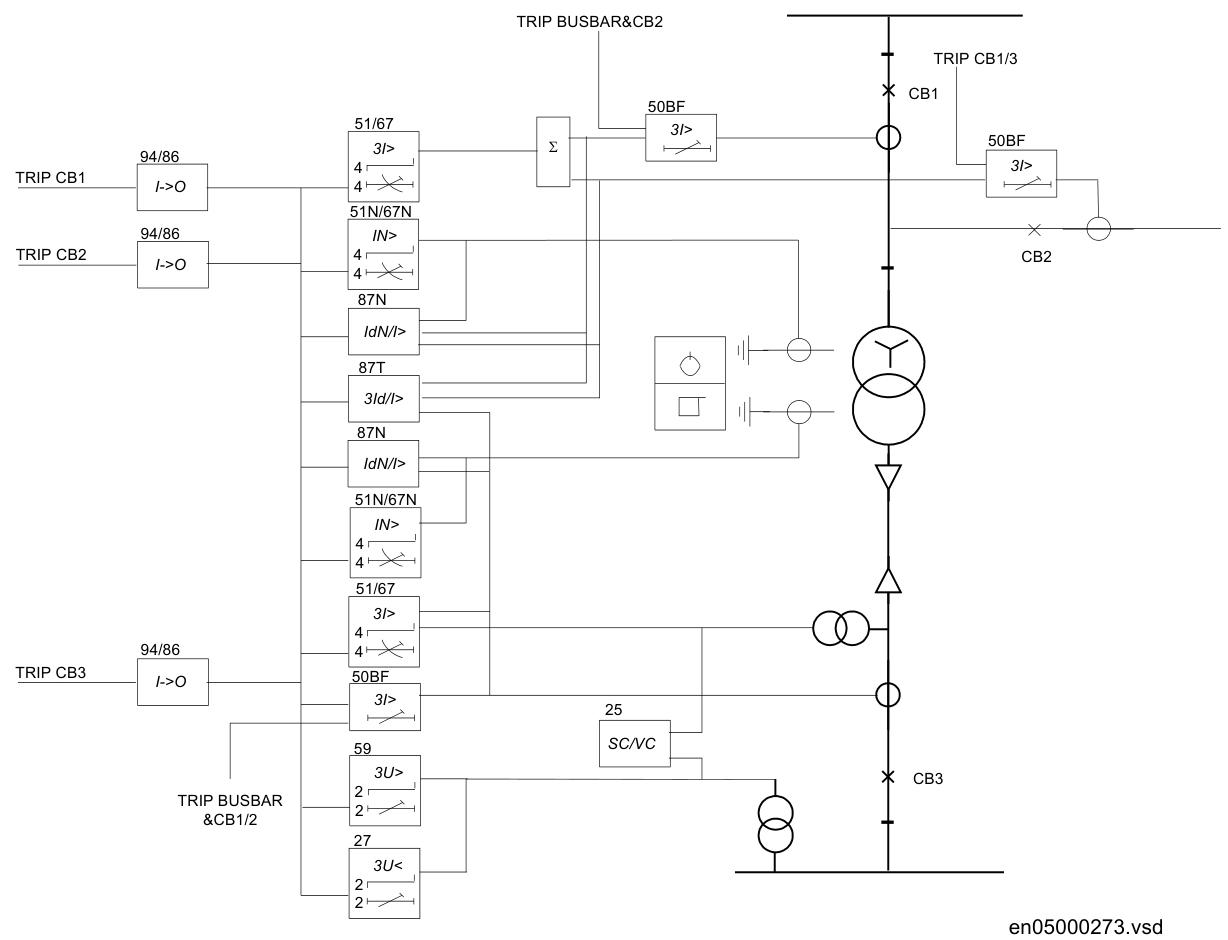

3.1 Safety Function

The controller is equipped with safety-related digital inputs and outputs, safety-related counters

and safety-related analog inputs.

3.1.1 Safety-Related Digital Inputs

The controller is equipped with 24 digital inputs. The state (HIGH, LOW) of each input is

signaled by an individual LED.

i The LEDs for the digital inputs are activated by the program if the F35 is in RUN.

The input signals are captured analogically and made available as INT values from 0...3000

(0...30 V) to the program.

i The digital inputs must not be used as safety-related analog inputs!

Configurable thresholds are used to generate BOOL values.

The default setting is:

Low level: < 7 V High level: > 13 V

The thresholds are set using system parameters, see Table 43 and Table 44. A difference of at

least 2 V must be maintained between the thresholds.

Mechanical contacts without own power supply or signal power source can be connected to the

inputs. Potential-free mechanical contacts without own power supply are fed via an internal

short-circuit-proof 24 V power source (LS+). Each of them supply a group of 8 mechanical

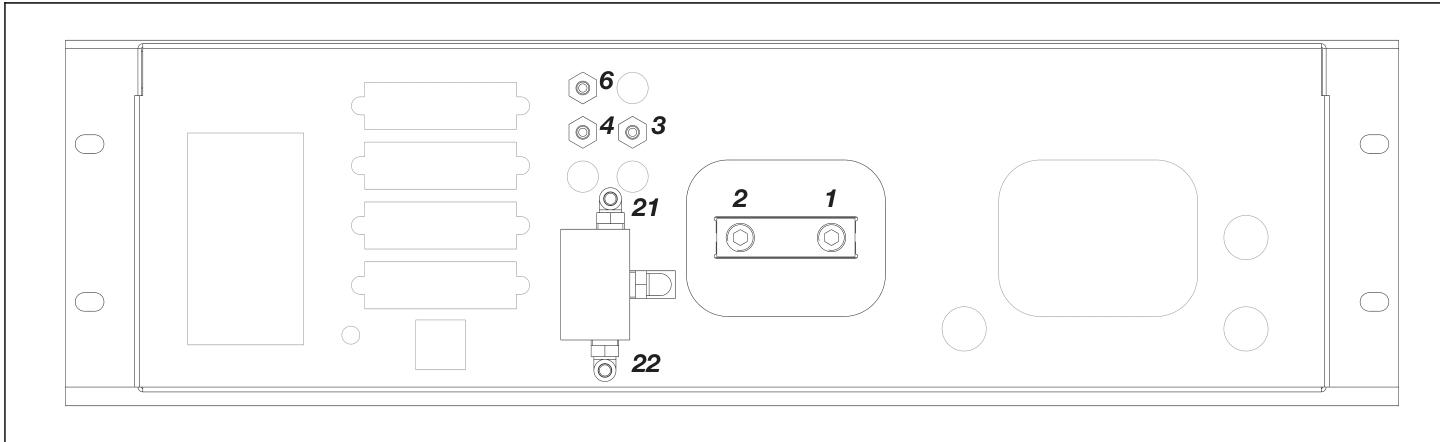

contacts. Figure 1 shows how the connection is performed.

With signal voltage sources, the corresponding ground must be connected to the input (L-), see

Figure 1.

Figure 1: Connections to Safety-Related Digital Inputs

For the external wiring and the connection of sensors, apply the de-energized-to-trip principle.

Thus, if a fault occurs, the input signals adopt a de-energized, safe state (low level).

An external wire is not monitored, however, an open-circuit is considered as safe low level.

3.1.1.1 Reaction in the Event of a Fault

If the device detects a fault on a digital input, the user program processes a low level in

accordance with the de-energized to trip principle.

The device activates the FAULT LED.

In addition to the channel signal value, the user program must also consider the corresponding

error code.

The error code allows the user to configure additional fault reactions in the user program.

3.1.1.2 Line Control

The detection of short-circuits and open circuits cannot be configured for the F35 system, e.g.,

on EMERGENCY STOP inputs complying with Cat. 4 and PL e in accordance with EN

ISO 13849-1.

Line monitoring for digital outputs is possible, see Chapter 3.1.4.1.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|