K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

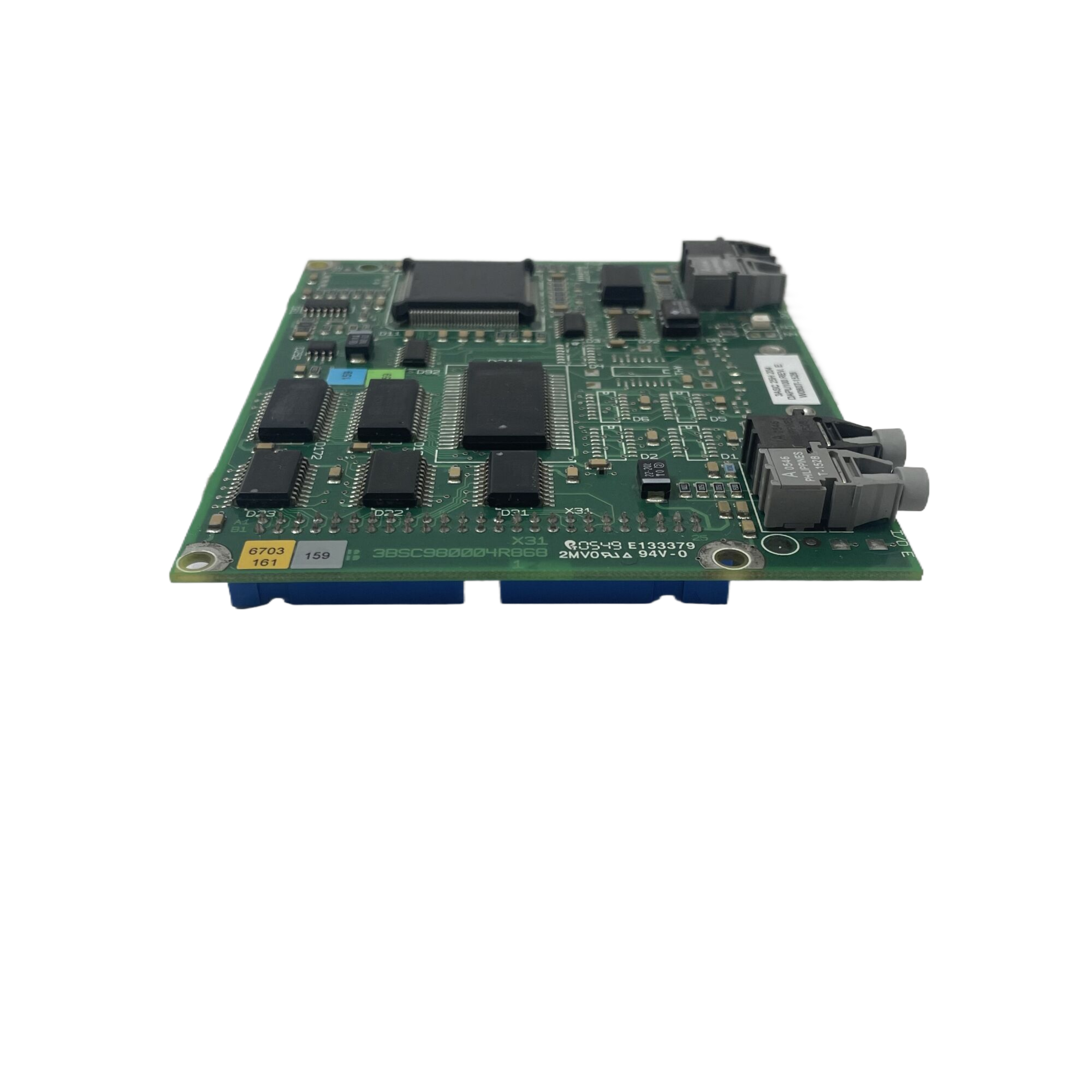

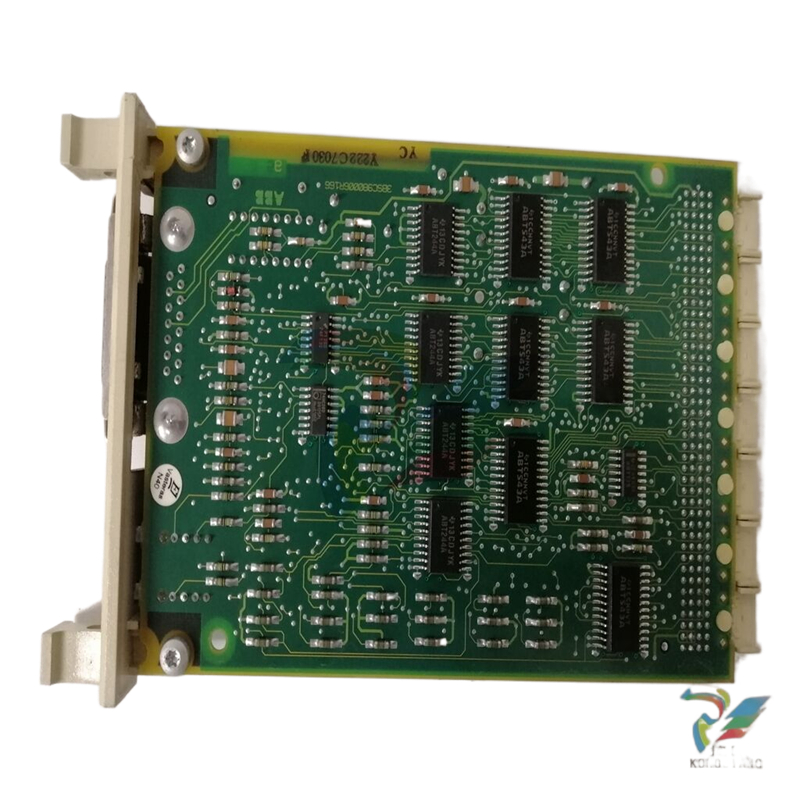

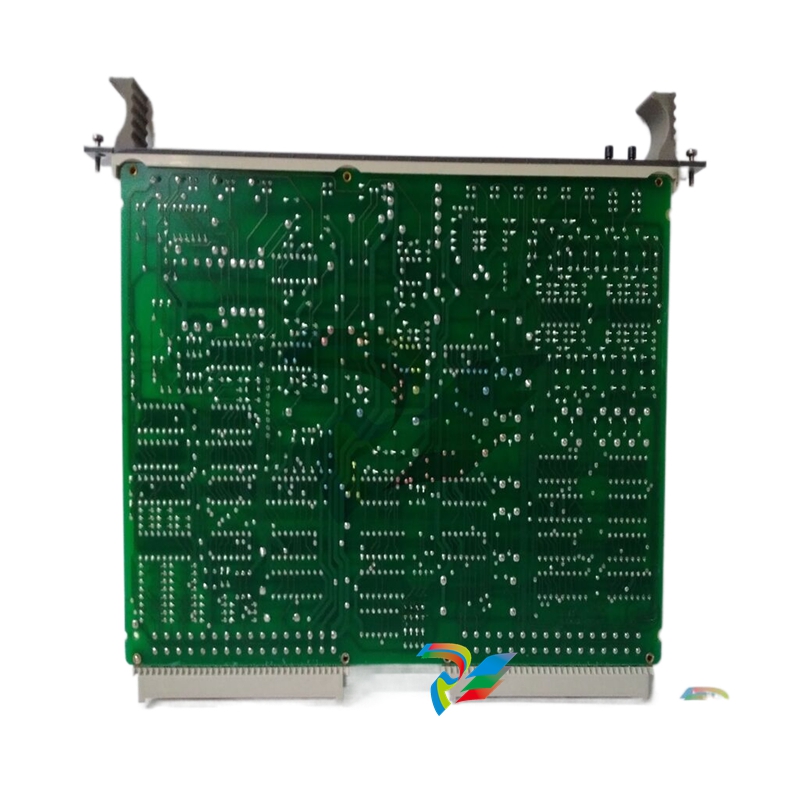

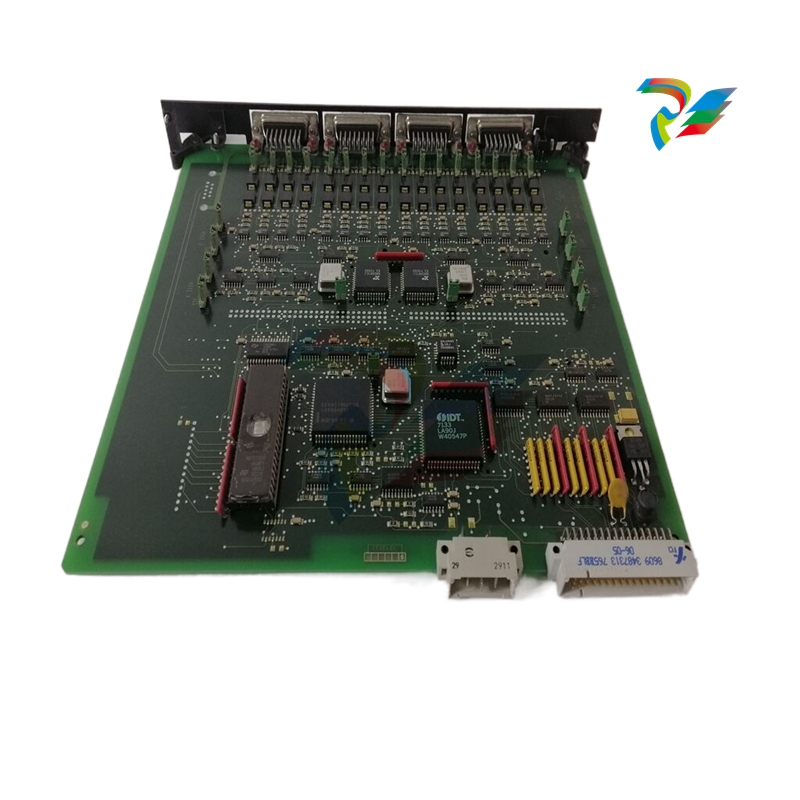

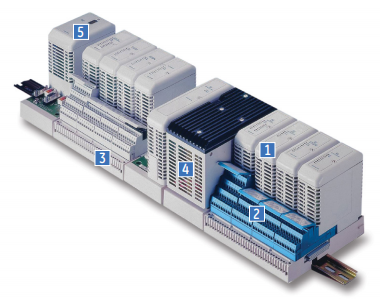

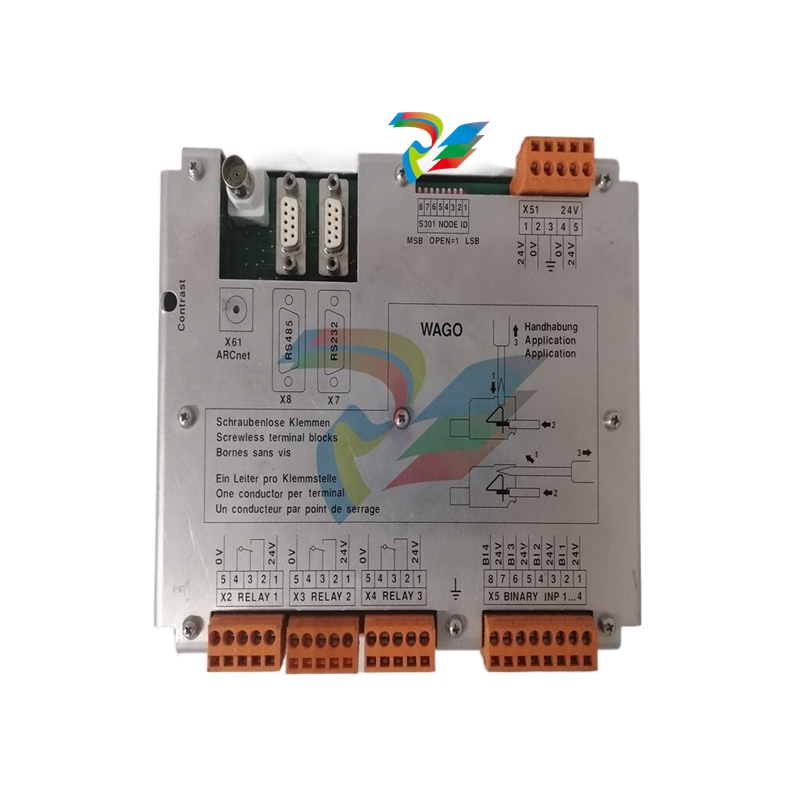

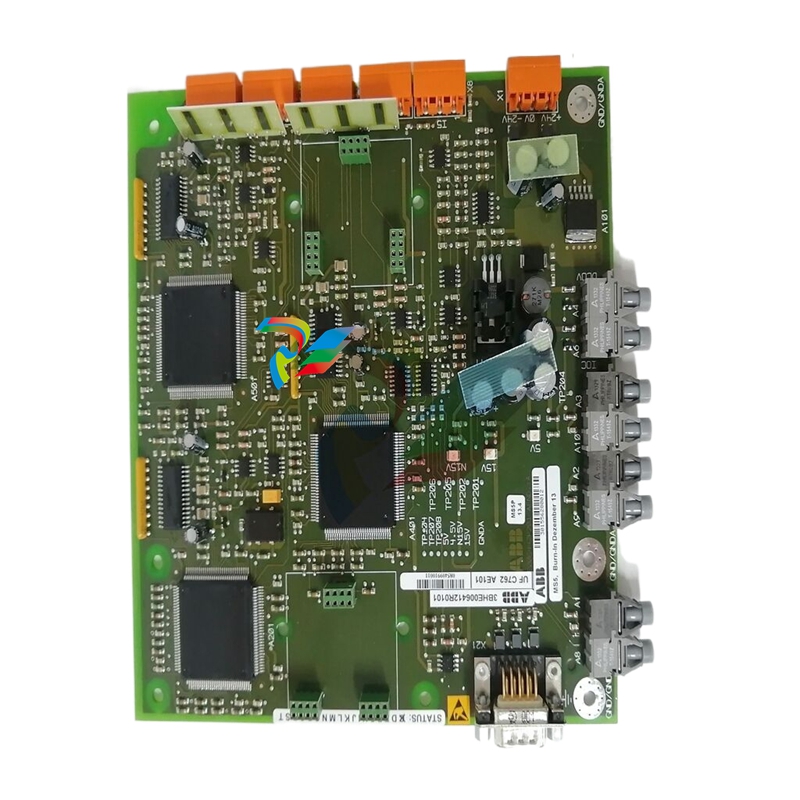

The Series 90-70 to RX3i I/O Adapter Card IC695ACC651 connects existing Series 90-70 field wiring to replacement RX3i I/O modules. It is used along with the S90-70 9-Slot Conversion Rack IC695ACC650 or the S90-70 5-Slot Conversion Rack IC695ACC652

GE FANUC IC695ACC651 I/O Adapter

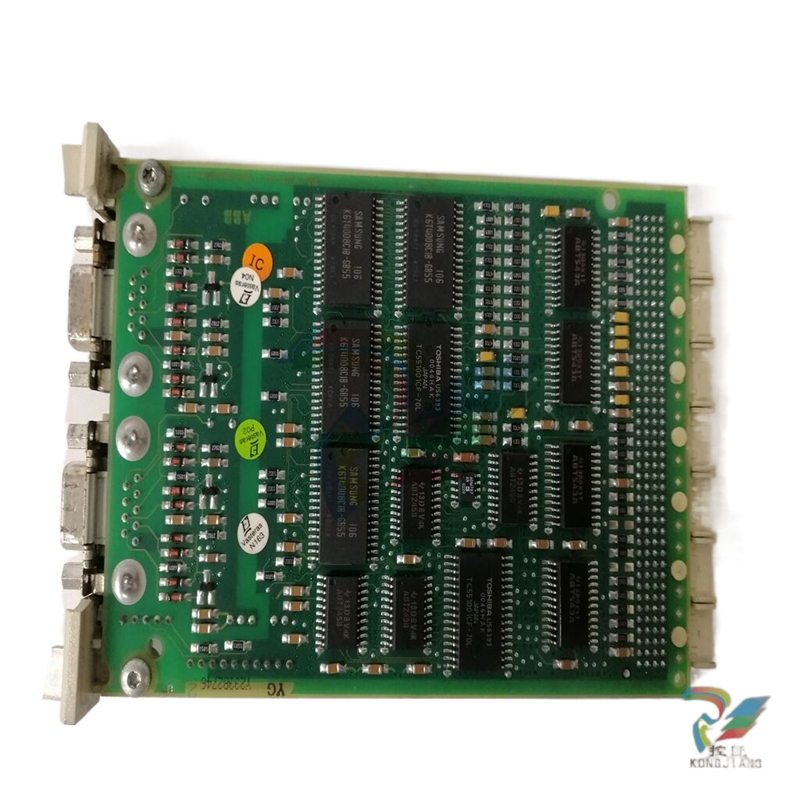

Compatible with Series 90-70 I/O terminal blocks

Supports Series 90-70 Discrete I/O and Analog I/O Modules. Refer to the section,

Supported Modules for Migration.

Supports up to 240 V 8A connections to I/O modules.

Surrounding Air Temperature Rating: 60˚C (140 ˚F)

Chapter 2 Installation and Set-Up

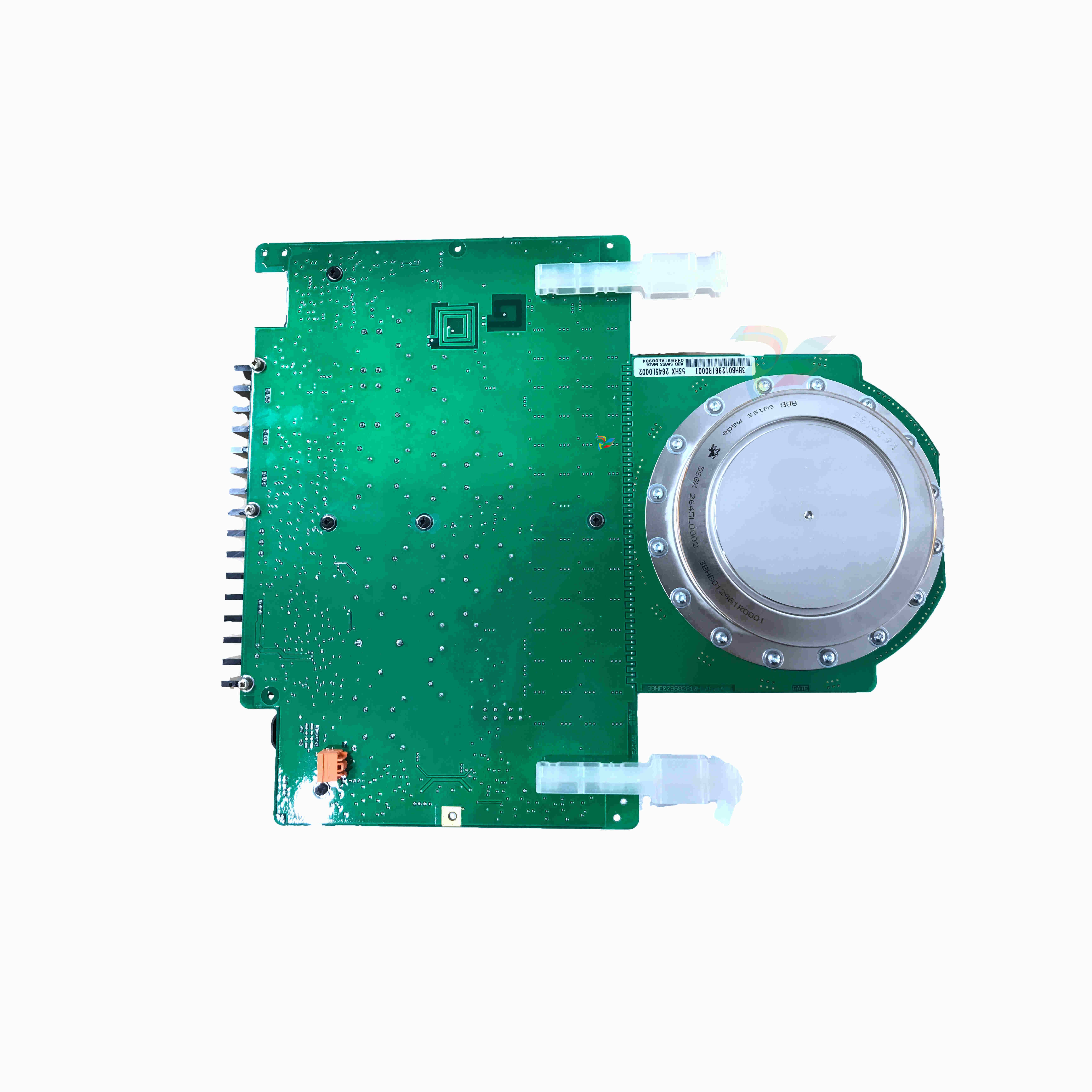

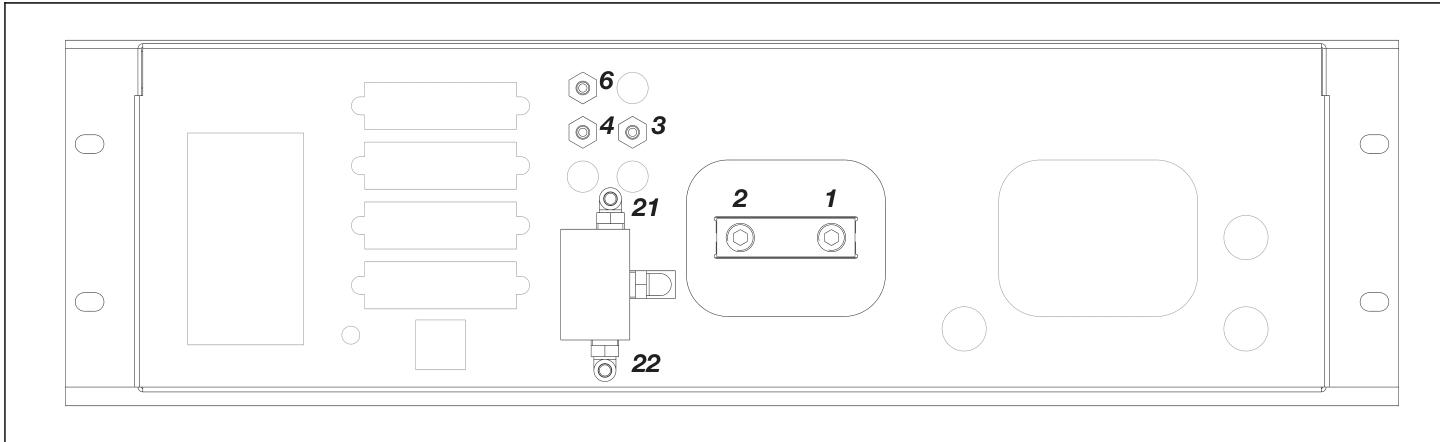

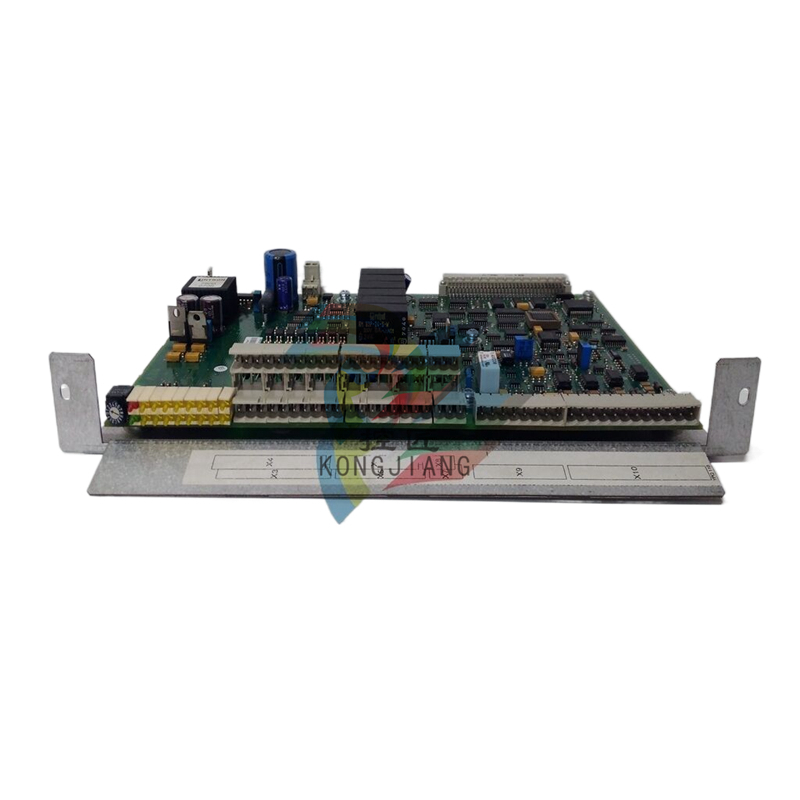

The Series 90-70 I/O terminal block assembly, with field wiring retained from the existing

Series 90-70 installation, should be plugged in to item A of the adapter card. Refer to Figure 2.

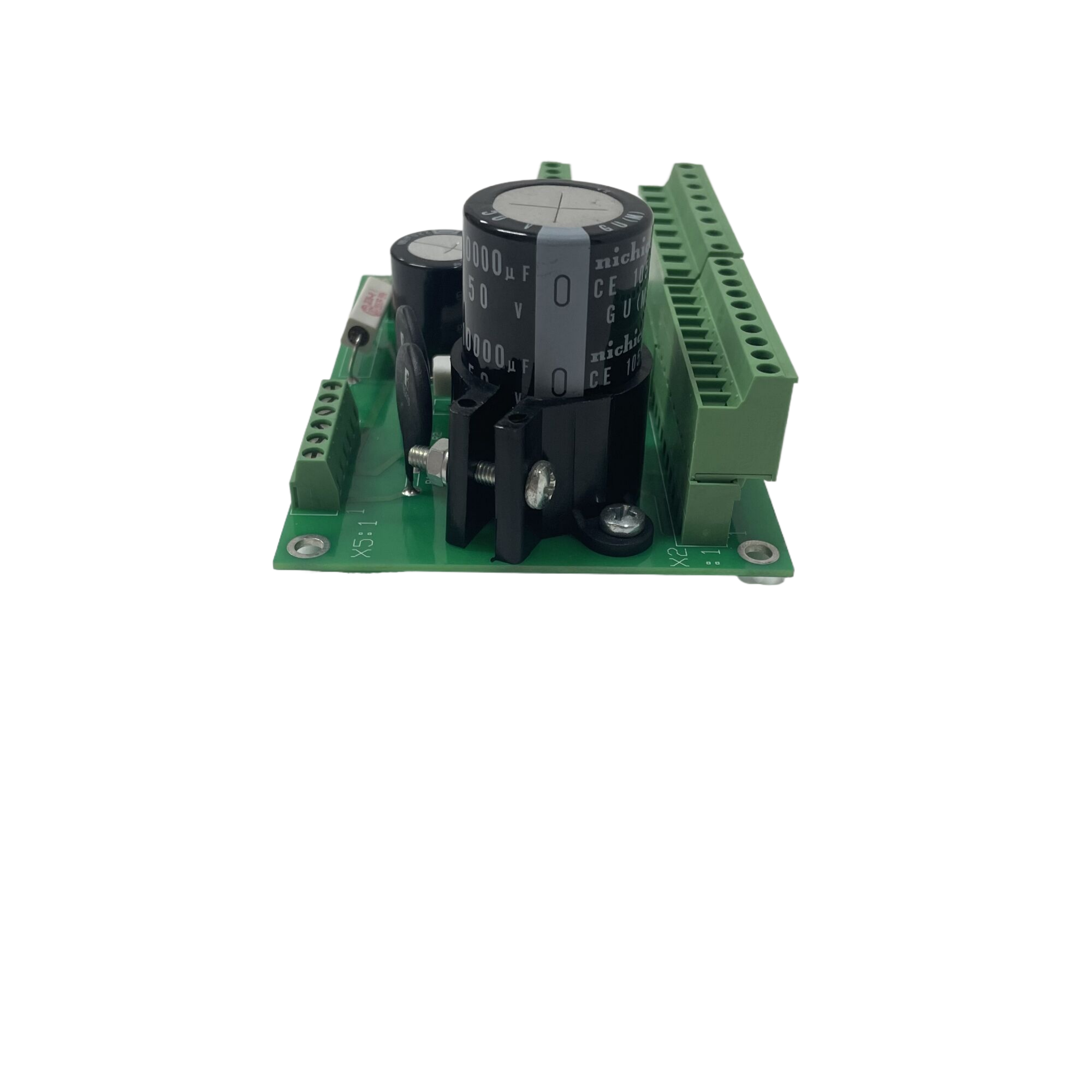

The other side of the I/O adapter card has 5 mm (0.20 in) pitch terminal blocks. Item B in

Figure 2 can be used to connect wires to the RX3i I/O module terminal headers. Refer to

Series 90-70 to RX3i Conversion Rack Important Product Information, GFK-2792. for

integration with either of the available conversion racks (IC695ACC650 or IC695ACC652).

2.1 I/O Adapter Card Installation

The IC695ACC651 I/O Adapter Cards have molded latches that automatically snap onto the

upper and lower rails of the conversion rack (IC695ACC650 or IC695ACC652) when the

module is fully inserted. Use the included M2.5x11 collar screws to secure the adapter cards

to the rack.

2.2 Removing an I/O Adapter Card

Warning

Remove the power supply connected to the Series 90-70 rack before disconnecting

terminal blocks or removing an Adapter card.

Even if the power supply is switched off, hazardous Voltages from user field wiring may still

be present on the I/O terminal boards as well as on the power supply terminal board. Care

should be taken when handling the power supply and I/O modules as well as any wiring

connected to them to prevent personal injury.

When removing an I/O Adapter Card from its slot in a rack adhere to the following

instructions:

If the series 90-70 I/O terminal block assembly is already connected to the I/O adapter

card, first remove it by turning the jackscrew counterclockwise until it is completely

disengaged.

Gently pull the series 90-70 I/O terminal block assembly from the bottom of the

conversion rack which is open.

Unscrew the M2.5x11 collar screws on the I/O adapter card.

Grasp the I/O adapter card firmly at the top and bottom of the board cover with your

thumbs on the front of the cover and your fingers on the plastic clips on the back of thec

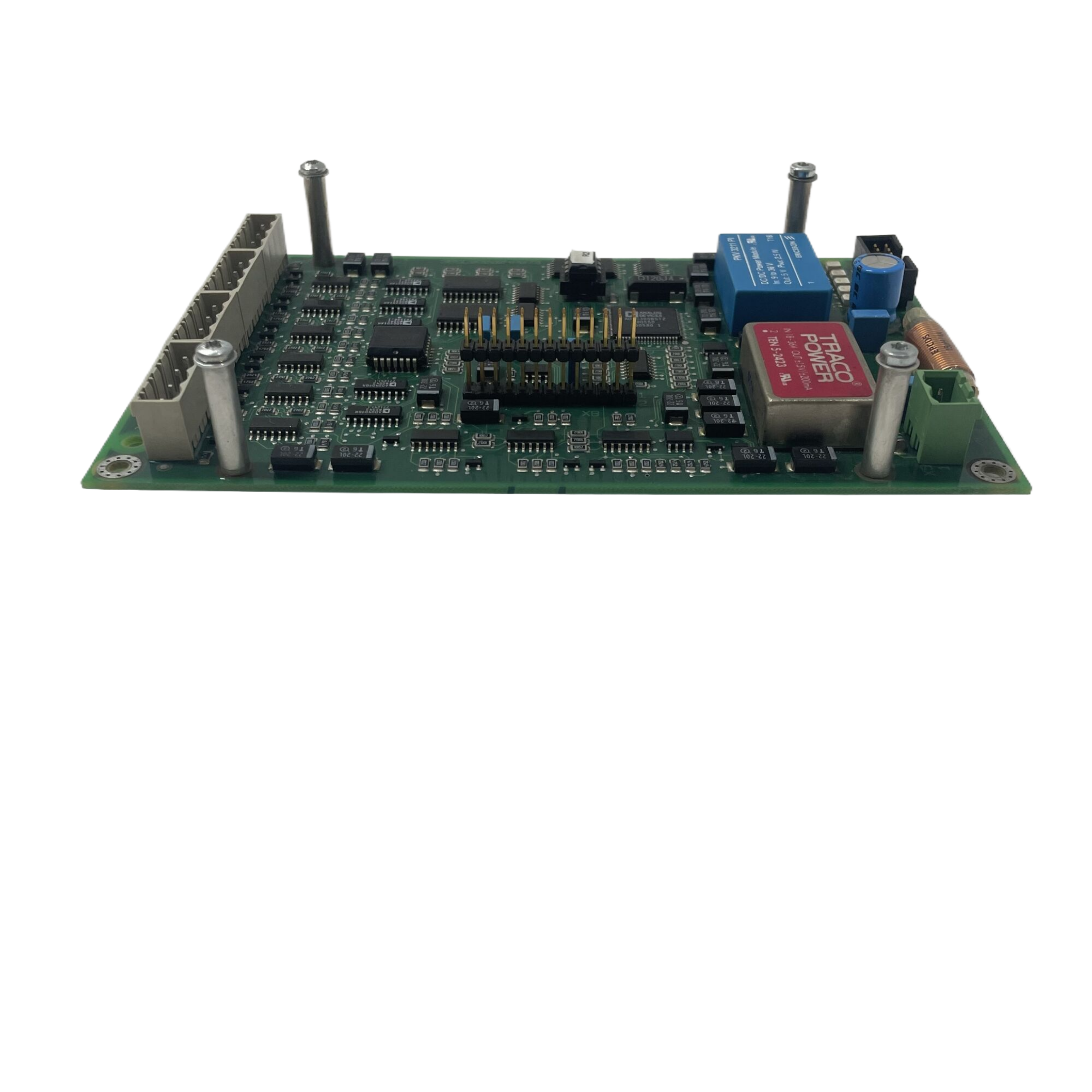

The following procedures should be used when connecting the wiring between the terminal connectors on the

adapter board and RX3i terminal block.

To connect the wiring

1. Turn off power before wiring the terminal connectors.

2. Choose the appropriate RX3i terminal block or blocks. Refer to GFK-2314. PACSystems RX3i System Manual.

3. The terminal connector on the I/O adapter card (item B in Figure 2), accepts wire sizes from AWG #22

(0.36 mm2) through AWG #14 (2.10 mm2). When using AWG #14 (2.10 mm2) wire for wiring all points, do not

exceed a max insulation diameter of 3.43 mm (0.135 in). To ensure proper connection, two wires may be

terminated at one terminal only if both wires are the same size.

4. The torque recommended for the I/O terminal board connection screws and the I/O adapter card Terminal

Block is as listed in the following table.

Connector Description Torque (min) Torque (max)

44B740021-G01R01 RX3i 20PT Terminal Block 1.1 Nm (9.6 in-lbs) 1.3 Nm (11.5 in-lbs)

IC694TBB032/TBB132 RX3i 36PT Terminal Block - 0.79 Nm (7 in-lbs)

42G8401-0067 CONN TB 1X10 5MM on I/O Adapter Card 0.5 Nm (4.4 in-lbs) 0.6 Nm (5.31 in-lbs)

5. For the ALG modules, to minimize capacitive loading and noise, all field connections should be wired using

a good grade of twisted, shielded instrumentation cable. The shields should be connected to GND on the

user terminal connector block.

Follow the wiring connections mapping provided in the following sections for each Series 90-70

I/O module to that of the equivalent RX3i I/O module.

6. After the wiring is completed from the I/O adapter card to the RX3i terminal strips, open the hinged RX3i

mounting plate on the adapter rack, insert the adapter card in the rack and gently pull the RX3i terminals

connected to the other side of the wire, from the bottom of the rack, which is open. To secure the I/O

Adapter card, refer to the procedures in the section, I/O Adapter Card Installation.

7. To connect the Series 90-70 I/O header assembly with field wiring to t

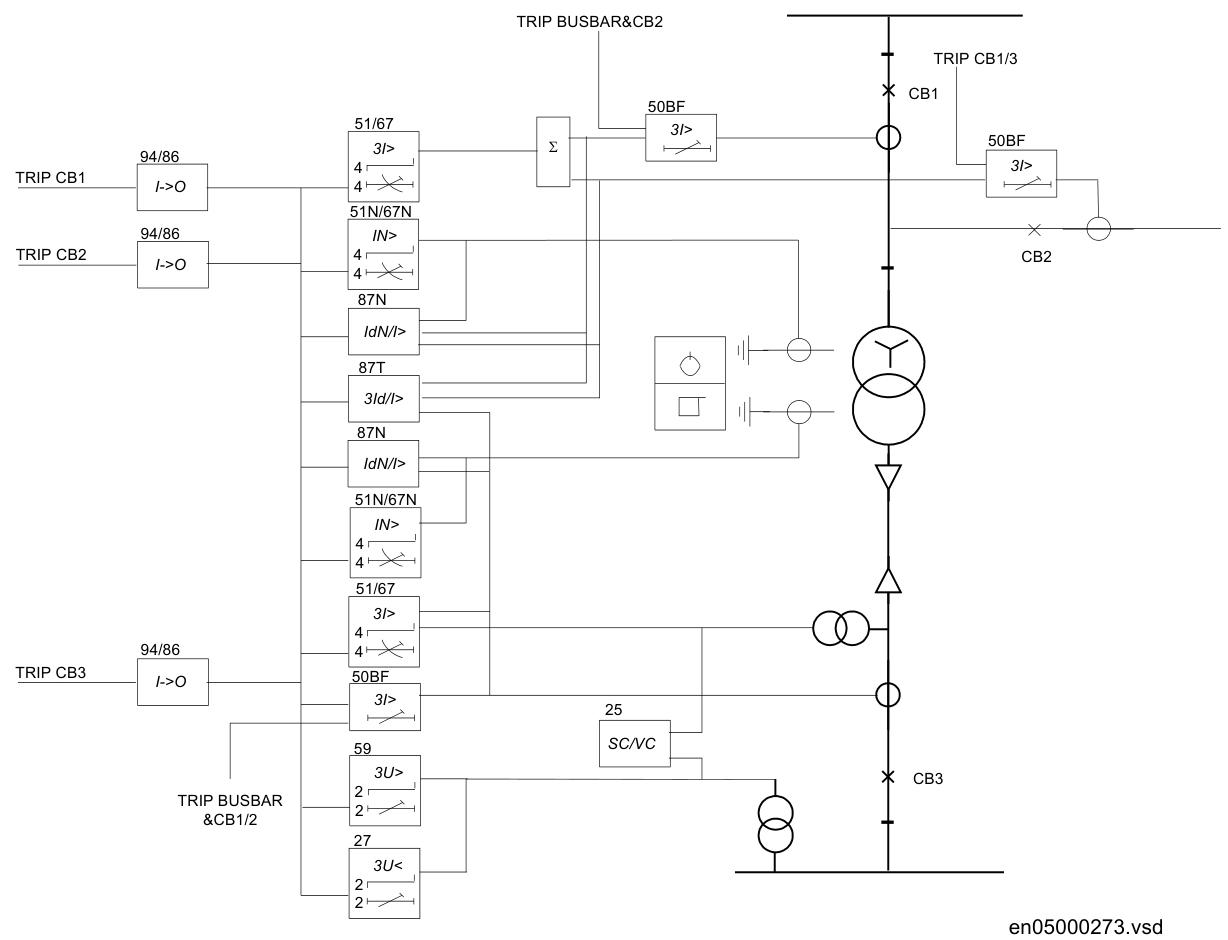

This chapter provides connector pin mapping and specifications for each combination of

Series 90-70 I/O and RX3i I/O modules. For Series 90-70 I/O modules, where multiple options

of wiring harnesses are offered, refer to the section, Modules Supported for Migration, for the

appropriate RX3i I/O module.

Notes:

The module mappings provided are the most optimal recommended solutions and apply

to installations that conform to those provided in GFK-0262. Series 90-70 Programmable

Controller Installation Manual, and GFK-0600. Series 90-70 Programmable Controller Data

Sheet Manual. It is the customer’s responsibility to validate their installation for

compliance to agency requirements.

It is recommended to review the isolation specifications for discrete modules and Form A

and C applications for relay modules when configuring the RX3i system.

Some applications require more than one RX3i module to transfer the Series 90-70 I/O. In

these cases, adjustments must be made in the user’s program.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|