K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

Digital Positioner for the

positioning of pneumatically

controlled final control elements.

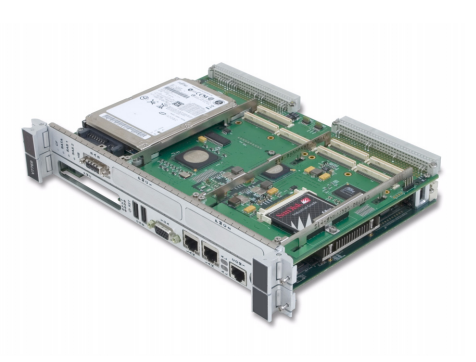

ABB 07CR41 1SBP260020R1001 Expansion Module

2 Use in potentially explosive atmospheres ange from one to two columnsGeneral requirements

• The ABB positioner has been approved only for appropriate

and intended use in standard industrial atmospheres. Any

breach of this rule leads to a cancellation of warranty and

manufacturer's responsibility!

• Make sure that only devices which comply with the types of

protection relevant to the applicable zones and categories

are installed.

• All electric equipment has to be suited for the respective

intended use.

Commissioning, Installation

The ABB positioner has to be mounted in a major system.

Depending on the degrees of IP-protection, an interval for

cleaning the equipment (dust settlement) has to be defined.

Strict care has to be taken that only devices which comply with

the types of protection relevant to the applicable zones and

categories is installed. When installing the device, the locally

applicable installation regulations, such as EN 60079-14, must be

observed.

Other important facts to be observed:

• The electric circuits of the positioner must be put into

operation in all zones by persons qualified in accordance

with TRBS 1203. The details on the type label are

mandatory for doing this.

• The device has been designed in accordance with IP 65

(optionally IP 66) and must be protected accordingly

against adverse ambient conditions.

• The EC Type Examination Certificate has to be taken into

account, including any special conditions defined therein.

• The device may only be used in accordance with its

intended use.

• The device may only be connected when de-energized.

• The potential equalization of the system must be

established in accordance with installation regulations

applicable in the respective country (VDE 0100, part 540,

IEC 364-5-54).

• Circulating currents must not be guided through the

housing!

• Make sure that the housing is properly installed and that

its IP rating has not been compromised.

• In potentially explosive atmospheres, assembly may be

conducted only in compliance with locally applicable

installation regulations. The following conditions have to

be observed (incomplete):

- Assembly and maintenance may only be conducted if

there is no explosion hazard in the area and you have a

hot work permit.

- The TZIDC may be operated in a fully mounted and

intact housing only.

Notes for operation

• The positioner must be integrated in the local potential

equalization system.

• Only either intrinsically safe or non intrinsically safe circuits

may be connected. A combination is not permit - ted.

• If the positioner is operated with non intrinsically safe

circuits, later use for the intrinsic safety type of protection is

not permitted.

Use, operation

The TZIDC is approved for proper and intended use only. In case

of non-compliance, the warranty and manufacturer’s liability do

no longer apply!

• Only those auxiliary components which fulfill all the

requirements of European and national standards may be

used in potentially explosive atmospheres.

• The ambient conditions specified in the operating

instruction must be strictly followed.

• The TZIDC is approved for proper and intended use in

standard industrial atmospheres only. Where aggressive

substances are present in the air, the manufacturer has to be

consulted.

2 Use in potentially explosive atmospheres

Maintenance, repair

Definition of terms according to IEC 60079-17:

Maintenance

Defines a combination of actions performed to maintain or

restore the condition of an item such that the item meets the

requirements of the relevant specification and performs its

required functions.

I ¬Analyzer module without electronics module (power supply):

Defines an action which involves careful inspection of an item

(either without disassembly or with partial disassembly, as

required) supplemented by measurements, aimed at achieving a

reliable conclusion regarding the condition of the item.

Visual inspection

Defines an inspection which identifies defects which are visible

to the naked eye, such as missing screws, without the use of

access equipment and tools.

Close inspection

Defines an inspection which encompasses the aspects covered

by a visual inspection and in addition, identifies defects such as

loose screws, which can only be detected with the use of access

equipment (e.g. steps) and tools.

Detailed inspection

Defines an inspection which encompasses the aspects covered

by a close inspection and in addition, identifies defects, such as

loose connections, which can only be detected by opening the

housing and / or by using tools and test devices, as needed.

• Maintenance and exchange work may be conducted by

qualified specialists only, i.e., qualified personnel in

accordance with TRBS 1203 or similar.

• Only those auxiliary components which fulfill all the

requirements of European and national guidelines and

regulations may be used in potentially explosive

atmospheres.

• Maintenance works that require disassembly of the system

may only be performed in non-hazardous areas. If that is not

possible, however, the usual precautions have to be ensured

according to local regulations.

• Components may only be replaced by original spare parts

which are therefore approved for use in potentially explosive

atmospheres.

• The device must be regularly cleaned when used in

potentially explosive atmospheres. The intervals must be

defined by the operator in compliance with the ambient

conditions present at the operating location.

• After all maintenance and repair work has been completed,

any barriers and plates removed for that purpose must be

put back in their original place.

• The flameproof joints differ from the tables of IEC 60079-1

and may be repaired by the manufacturer only.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923