K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

ControlEdge HC900 I/O modules use terminal blocks with

various features available.

Honeywell Digital Input, 24VDC (16 channel)900G02-0202

Terminal Blocks (900TEK-xxxx, 900TBK-xxxx, 900TER-xxxx, 900TBR-xxxx)ControlEdge HC900 I/O modules use terminal blocks with

various features available.

Terminals are available in Barrier style and Euro style.

The Barrier style terminal block provides a floating

washer to accommodate two different size conductors.

The Euro style offers a more compact terminal design

providing more room within the terminal block cavity for

conductors.

All terminal blocks support customer wiring entering the

block from the top or bottom when mounted in the

controller. A locking swing out door provides easy access

for wiring and covers potential high voltage connections

during operation.

For low voltage terminals accepting thermocouple inputs,

cold junction compensation is provided by the AI

modules.

Terminal blocks are secured to the rack assembly with

screws. These screws provide vibration immune terminal

connections during operation and also serve as jacking

screws when removing modules to minimize the

extraction force required.

The rear of the Terminal block provides keying to prevent

accidental terminal block insertion into incorrect module

slots. Labels are provided to identify the module type by

name and color, offer wiring instructions and provide an

area for customer identification of field circuits. Shorting

combs are available for use with Barrier terminal blocks

to connect common signal pairs together or to jumper

together common signals on AC and Relay output

modules.

Shield terminal strips are also available to terminate the

shields of shielded cables at the controller.

Number of

terminals

20 36*

Type Terminal blocks removable

under instrument power.

(Field power disconnected)

Terminal blocks removable

under instrument power.

(Field power disconnected)

Gauge Wires Barrier and Euro: #14 to 26

AWG, solid or stranded

Euro: #12 to 26 AWG, solid

or stranded

Terminal color High voltage: Red

Low Voltage: Black

Black

Contacts High Voltage: Tin Coated

Low Voltage: Gold Plated

Gold plated

Contact Style Post and socket Post and socket

Door Access Tool accessible Tool accessible

Cold Junction

compensation for

thermocouples

Yes (provided by AI

module)

N/A—thermocouples not

used

*Required with the following I/O modules: 16 HL AI, 8 AO, 16 AO, 32 DI, 32

DO and 16 AC/DC DI.

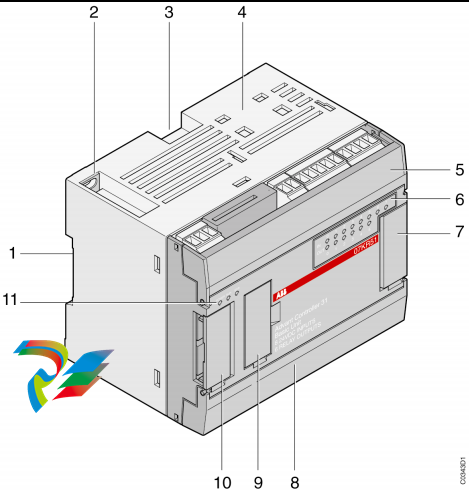

I/O Scanner Module (900S50x-xxxx)

The I/O Scanner 1 module resides in a remote I/O rack

along with the I/O modules. The Scanner 1 and the

controller are connected to each other’s I/O port (see the

photo on the right side of this page). The scanner collects

data from the Input modules populated in its remote rack

and communicates the information to the controller.

Output data is sent from the controller to the Scanner 1

module which in turn sends the data to appropriate output

module. Data exchanges are synchronous with the

controller scan time to maintain deterministic operation.

Diagnostic status of I/O modules is also monitored and

reported to the controller when detected. The Rack

address of a Scanner 1 is set via DIP switches on the

Scanner 1’s circuit board. Connection to the controller

uses IEEE 802.4 Ethernet 100base-TxPhysical Layer. An

external Ethernet switch is required when multiple I/O

scanners are used with a single controller. Scanner 1

modules do support removal and insertion under power.

Number of

terminals

20 36*

Type Terminal blocks removable

under instrument power.

(Field power disconnected)

Terminal blocks removable

under instrument power.

(Field power disconnected)

Gauge Wires Barrier and Euro: #14 to 26

AWG, solid or stranded

Euro: #12 to 26 AWG, solid

or stranded

Terminal color High voltage: Red

Low Voltage: Black

Black

Contacts High Voltage: Tin Coated

Low Voltage: Gold Plated

Gold plated

Contact Style Post and socket Post and socket

Door Access Tool accessible Tool accessible

Cold Junction

compensation for

thermocouples

Yes (provided by AI

module)

N/A—thermocouples not

used

*Required with the following I/O modules: 16 HL AI, 8 AO, 16 AO, 32 DI, 32

DO and 16 AC/DC DI.

Type I/O Scanner

Status indicators Scanner: Module status Red/Green LED indicates mode

or error

Expansion I/O port: Green and Yellow LEDs indicate

receive/transmit

Power supply loading 5V; 770 mA max

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923