K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

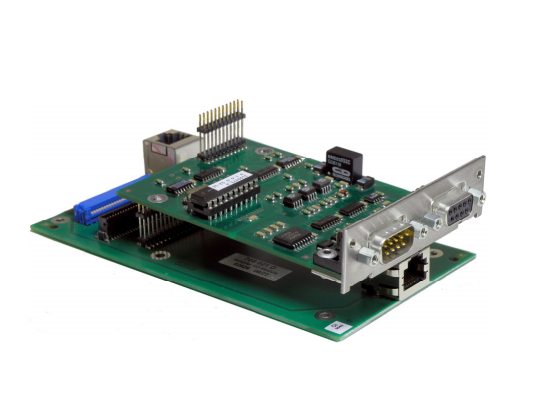

Information from the AO2000 gas analyzer can be transferred to a PC or DCS via

the Modbus. Measurement values, status signals and also signals of analog and

digital inputs and outputs are thus available for further usage.

ABB AO2000 gas analyzers

Transferred data Read Write Example

Measurement values x – CO, NO, H2, etc.

Analog inputs x – Indication of mA-values of external analyzers

Analog outputs x – Indication of mA-values of measurement values or calculated

values (function block application)

Digital inputs x – Indication of external status signals

Digital outputs x – Measurement range feedback, indication of solenoid or pump controls

Bus analog inputs x x Entering analog values into the function block application

Bus analog outputs x – Outputting analog values from the function block application

Bus digital inputs x x Control of functions such as auto calibration, measuring range

control, etc. after function block configuration

Bus digital outputs x – Indication of all functions integrated by function block configura tion such as alarm signaling etc.

Modbus configuration x – Indication how many components, AOs, DOs, etc. have been

configured or are in the gas analyzer

Status signals x – Indication of failure, maintenance mode, maintenance request

Measurement range feedback

x – Index of the active measurement range

Measurement range configuration

x – Measurement range limits (start and end value)

Measurement range drift values

x – Offset drift, amplification drift, delta offset drift, delta amplification drift

QAL3 calibration data x – Setpoints and actual values, measuring range and date of last

calibration (not available in analyzer modules Limas11, Uras14,

Magnos16, Magnos106, Caldos15, Caldos17, and MultiFID14)

Data transfer For data transfer a combination of frames is used, that consists of 1/0 information,

united to one or more telegrams.

Frame The transfer values are decomposed in bytes (= 8 bit). Each of these bytes is

completed by one start-bit, possibly one parity-bit (even number of “1”) and one

stop-bit. In the following description the term “byte” will be used, even if ten or

eleven bits will be transferred including the start-, stop- and parity-bits.

Telegrams The Modbus telegrams consist of the following frames:

address (1 byte), function (1 byte), data (n bytes) and check sum (2 bytes).

The telegrams also take on the “shake-hands-function”: each telegram from

master to slave must be responded, before a new telegram is allowed to be

transmitted. The computer has to have in a adequate supervision, for excluding

non answering bus participants (time-out-supervision).

Admissible addresses As addresses for the participants of the bus the numbers 1 to 255 are admitted.

The address 0 is the global address (broadcast-address). When this address will

be used in a telegram, all participants accept this telegram without an acknowledg ment to the master.

Functions Code Term Function

01 Read coil status Reading of binary values of type coil

02 Read input status Reading of binary values of type status

03 Read holding registers Reading of 16 bit holding-registers

04 Read input registers Reading of 16 bit input-registers

05 Force single coil Setting of a single binary value

06 Preset single register Set of a single 16 bit-register; for DINT or

REAL two telegrams are necessary

08 Loopback diagnostic test Testing telegram for diagnostics of the

communication capability of slave

15 Force multiple coils Set of several successive binary values

16 Preset multiple registers Set of several successive 16 bit-registers

Check sum The check sum is calculated over all bytes of one telegram without the start-,

stop- and parity-bits.

Transfer rules The neutral position of the data line corresponds with the logical “1”.

A distance of more than 3.5 bytes, however at least 10 ms is defined as separation

between two telegrams. For the beginning of the data transfer the neutral position

of the data line must be observed.

Integration The AO2000 Modbus/TCP server expects requests from the current IP addresses

via the communication port. A maximum of 4 clients can be connected to the

Modbus/TCP server of an AO2000 at the same time. If the connection to a client

breaks down, the connection status in the Modbus/TCP server is enabled again

after a max. 60 seconds. Reading out data

from the AO2000 Modbus/TCP server

The following procedure must be executed on the Modbus client, in order to

receive data from the AO2000 Modbus/TCP server:

1. Establish a TCP connection to port 502 on the server.

2. Create a Modbus request.

3. Send the Modbus request incl. the Modbus/TCP MBAP Header.

4. Wait for a response to the same TCP connection.

5. Read the first 6 bytes of the response; these state the length of the response.

6. Read the remaining bytes of the response.

Functions, addressesand registers

The supported functions and the addresses and registers of Modbus over TCP/IP

are equivalent to those of Modbus over RS232/RS485.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923