K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

Synchronizing devices are widely used in power stations or

industrial installations with their own power generating facilities,

where the generators need to be paralleled with an island line

or a public line, or in power distribution systems.

ABB SYNCHROTACT Synchronizing devices

Synchronizing devices are widely used in power stations or

industrial installations with their own power generating facilities,

where the generators need to be paralleled with an island line

or a public line, or in power distribution systems.

Power circuit breakers may only be closed if both voltages are

approximately synchronous (coincident). Otherwise, faults in

line operation, loading of the generators and, in extreme cases,

damage to the generators can result.

SYNCHROTACT® 5 performs these functions safely and reliably,

whether as a monitoring element for manual paralleling or as

an independent fully-automatic synchronizing device.

SYNCHROTACT® 5

Range of applications

1. Automatic synchronizing and paralleling of synchronous generators

with line.

2. Automatic paralleling for synchronous and asynchronous lines,

transmission lines and busbars.

3. Paralleling monitoring (synchrocheck) for the monitoring of

automatic or manual paralleling procedures including the

connection of voltage-free lines (dead bus).

SYNCHROTACT® 5

Principle of operation

The synchronizing and paralleling process can be divided

into the following blocks

Measuring

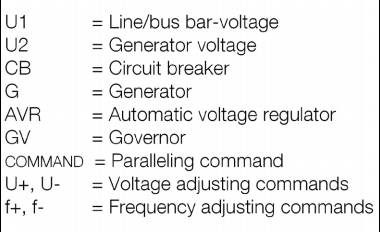

Voltage difference ΔU (amplitude), slip s (frequency diffe rence), and phase-angle α, are all required for paralleling.

These values are formed from the two measurement signals

U1 and U2 (see illustration, left).

Matching

Voltage and frequency matching functions reduce the voltage

difference ΔU, and slip s by sending adjusting pulses to the

voltage or turbine regulators.

Monitoring of paralleling conditions

This function compares the actual values with their set

maximum values and releases paralleling (CHK RELEASE) if

all conditions are fulfilled simultaneously.

Synchrocheck mode (paralleling monitoring)

In synchrocheck mode, only the measuring and monitoring

function blocks are active. The output relay is closed during

paralleling release.

Command generation

The command generation calculates the necessary lead angle

αv, by which the paralleling command must be advanced

due to closing time delay. The action ensures that the main

contacts close at precisely the right time. If α reaches αv at

the same time as paralleling release (CHK RELEASE), the

command is issued. Under synchronous conditions, ie,

permanent paralleling release during the adjustable monitoring

time, tsup, the CMD is also issued without taking the lead

angle into consideration.

From a synchronizing device, it is expected to close the

power circuit breaker at the correct time but also that, if

required, paralleling can take place whenever permissible.

Although the series connection of the output contacts of two

independently-functioning channels (dual-channel system),

which is usual in synchronizing systems, greatly increases

security against incorrect paralleling, it necessarily leads to a

reduction in availability.

Single or dual-channel?

Not every synchronizing system needs to be structured

according to the above pattern. The SYNCHROTACT® 5

single-channel synchronizing devices offer a high degree of

security and are often used in practice. However, security

can be significantly increased by means of dual-channel

systems. It is unlikely that the two channels - of which the

hardware and software are structured differently - will have

the same malfunction simultaneously. The extra cost of a

dual channel system can prove beneficial compared to the

damage arising from incorrect paralleling.

Second, redundant synchronizing system?

Often, two redundant synchronizing systems are installed

in a single plant so that, in the event of one system failing,

the other can be used, thereby increasing availability. The

second system is often designed for manual synchronizing

with or without synchrocheck.

In addition, with SYNCHROTACT® 5, ABB offers two automatic

dual-channel systems in a single casing, thus avoiding

manual synchronizing.

Advantages of such a solution:

– No engineering and wiring costs for the second system

– Further increased security since all four output contacts

are normally operated in series

– No problems with synchronizing where the

manual synchronizing system is seldom used.

Specific settings for synchronizing and paralleling are stored

in a parameter set. Devices with seven parameter sets have

seven times the same parameters, with the possibility of

individual setting. That way, seven paralleling points with

individual settings may be operated. Firstly, the parameter

set, or the circuit breaker to be synchronized has to be

selected. Then the synchronizing process can be started.

The software-driven link between parameter set and

paralleling point guarantees the correct assignment of the

setting values to the related plant components

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923