K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

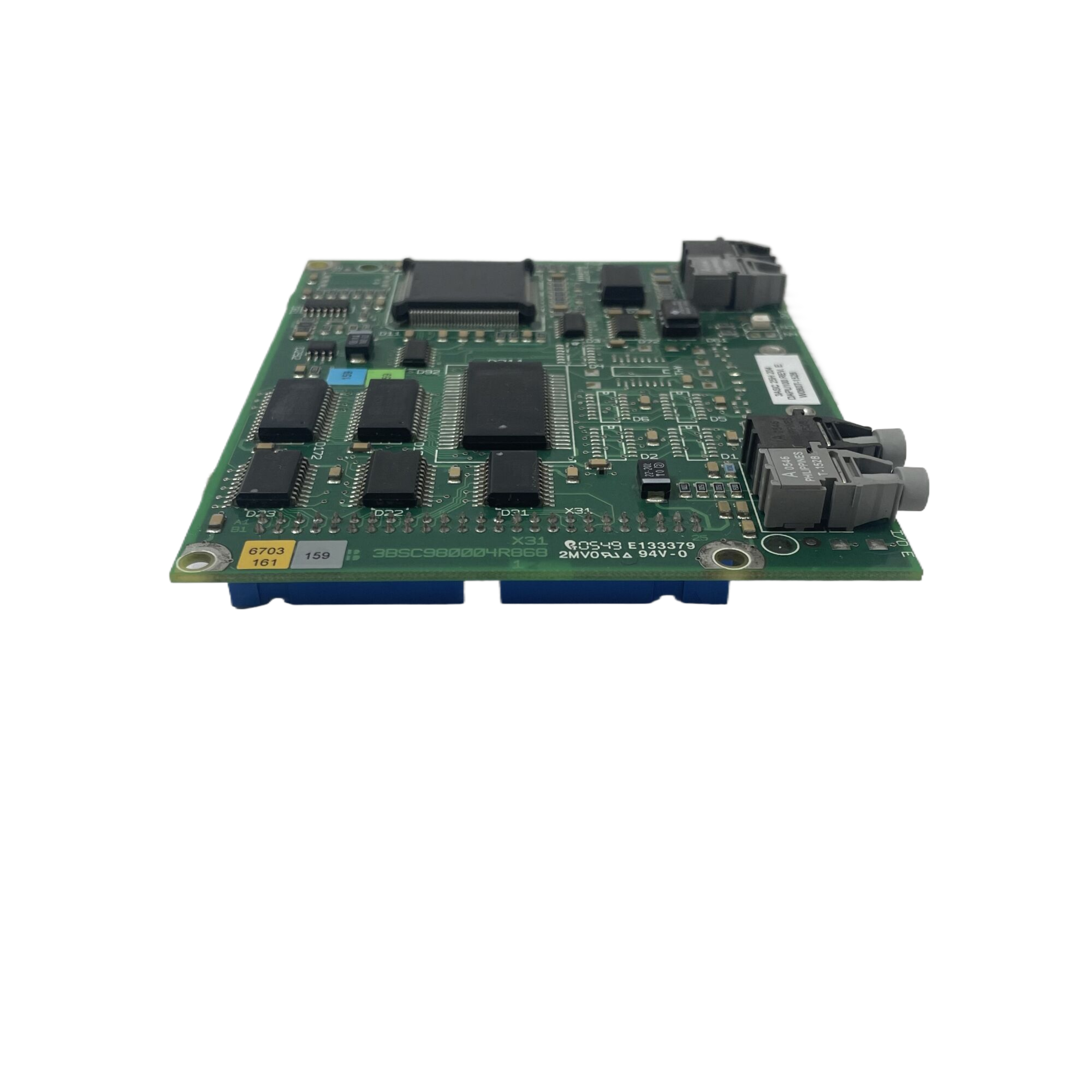

The RER 133 Bus Connection Module acts as an interfacing unit between an RE_54_ host device and a SPA, Modbus or DNP 3.0 system. The RER 133 module converts RS-232 signals to RS-485 signals. RS-485 can be connected by using 2- or 4-wire mode

ABB RER133 Bus Connection Module

The RER 133 module is connected by a cable to the RS-232 D-type connector

marked X3.2 on the rear panel of the RE_ 54_ host device. RER 133 is not a stand

alone device. An RE_ 54_ host device is always required to power the module. No

external power supply is supported.

RER 133 supports communication speeds from 300 to 19200 bits/s. Collision

detection and collision avoidance is supported for communication speeds 4800.

9600 and 19200 bits/s.

A RER 133 delivery includes the RER 133 Bus Connection Module, a connection

cable (1MRS120542) and this manual.

Principle of operation

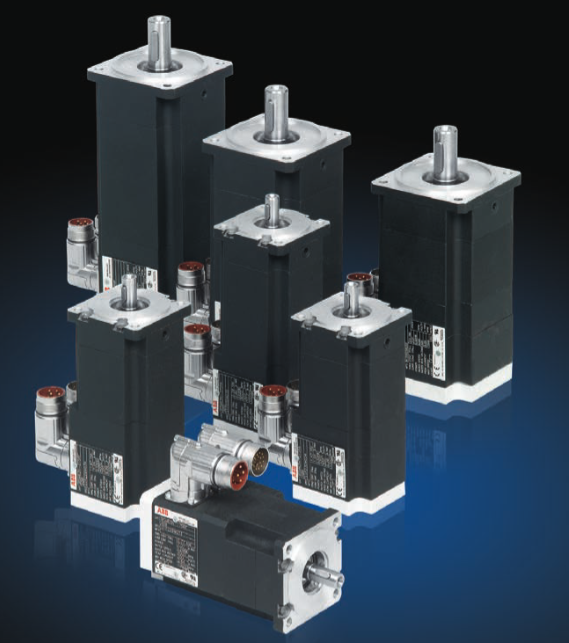

The RER 133 Bus Connection Module is designed to work with RE_ 54_ products.

The module utilizes the RS-232 communication port located on the rear panel of the

RE_ 54_. The module is not designed to be connected to any other ABB product,

nor to any third party products.

The signal levels and the functionality of the RER 133 module are defined in the

RS-485 standard. RER 133 module is a regular type of RS-485 interface, meaning

that a maximum of 32 nodes can be connected in a daisy chain type of bus

configuration.

Collision detection on the RS-485 bus is supported when a maximum of 32 nodes

are connected to the same daisy chain. In order for collision detection to operate, the

communication speed has to be set to 4800. 9600 or 19200 bits/s. These speeds are

set by using the DIP switches on the front of the module. For an example on how to

set these DIP switches, please see section ìModule configurationî on page 9. When

collision detection is not used, the communication speed does not have to be set.

General

The RER 133 Bus Connection Module acts as an interfacing unit between an

RE_54_ host device and a SPA, Modbus or DNP 3.0 system. The RER 133 module

converts RS-232 signals to RS-485 signals. RS-485 can be connected by using 2- or

4-wire mode.

The RER 133 module is connected by a cable to the RS-232 D-type connector

marked X3.2 on the rear panel of the RE_ 54_ host device. RER 133 is not a stand

alone device. An RE_ 54_ host device is always required to power the module. No

external power supply is supported.

RER 133 supports communication speeds from 300 to 19200 bits/s. Collision

detection and collision avoidance is supported for communication speeds 4800.

9600 and 19200 bits/s.

A RER 133 delivery includes the RER 133 Bus Connection Module, a connection

cable (1MRS120542) and this manual.

Principle of operation

The RER 133 Bus Connection Module is designed to work with RE_ 54_ products.

The module utilizes the RS-232 communication port located on the rear panel of the

RE_ 54_. The module is not designed to be connected to any other ABB product,

nor to any third party products.

The signal levels and the functionality of the RER 133 module are defined in the

RS-485 standard. RER 133 module is a regular type of RS-485 interface, meaning

that a maximum of 32 nodes can be connected in a daisy chain type of bus

configuration.

Collision detection on the RS-485 bus is supported when a maximum of 32 nodes

are connected to the same daisy chain. In order for collision detection to operate, the

communication speed has to be set to 4800. 9600 or 19200 bits/s. These speeds are

set by using the DIP switches on the front of the module. For an example on how to

set these DIP switches, please see section ìModule configurationî on page 9. When

collision detection is not used, the communication speed does not have to be set.

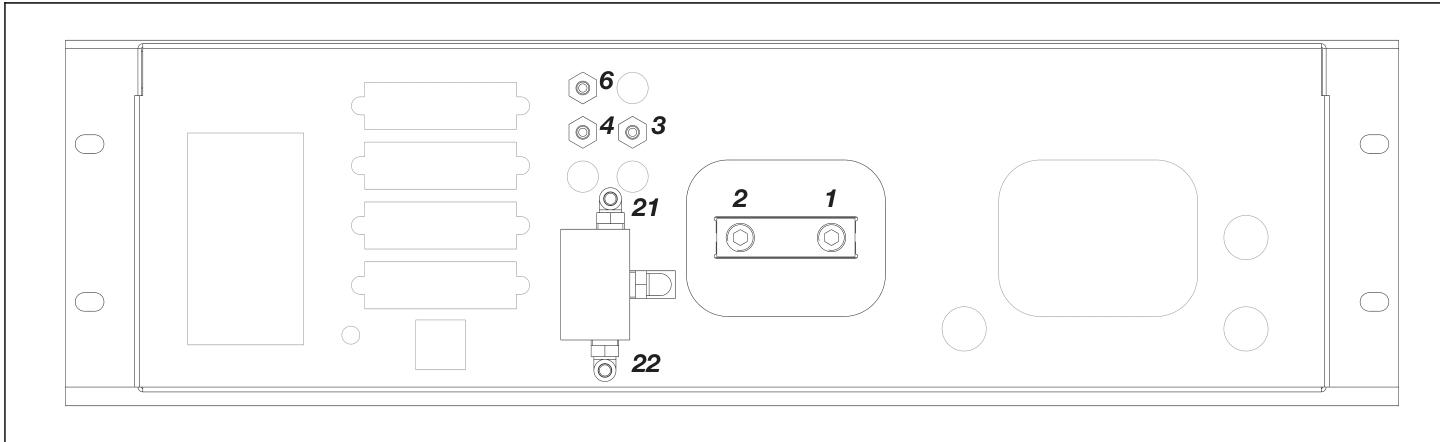

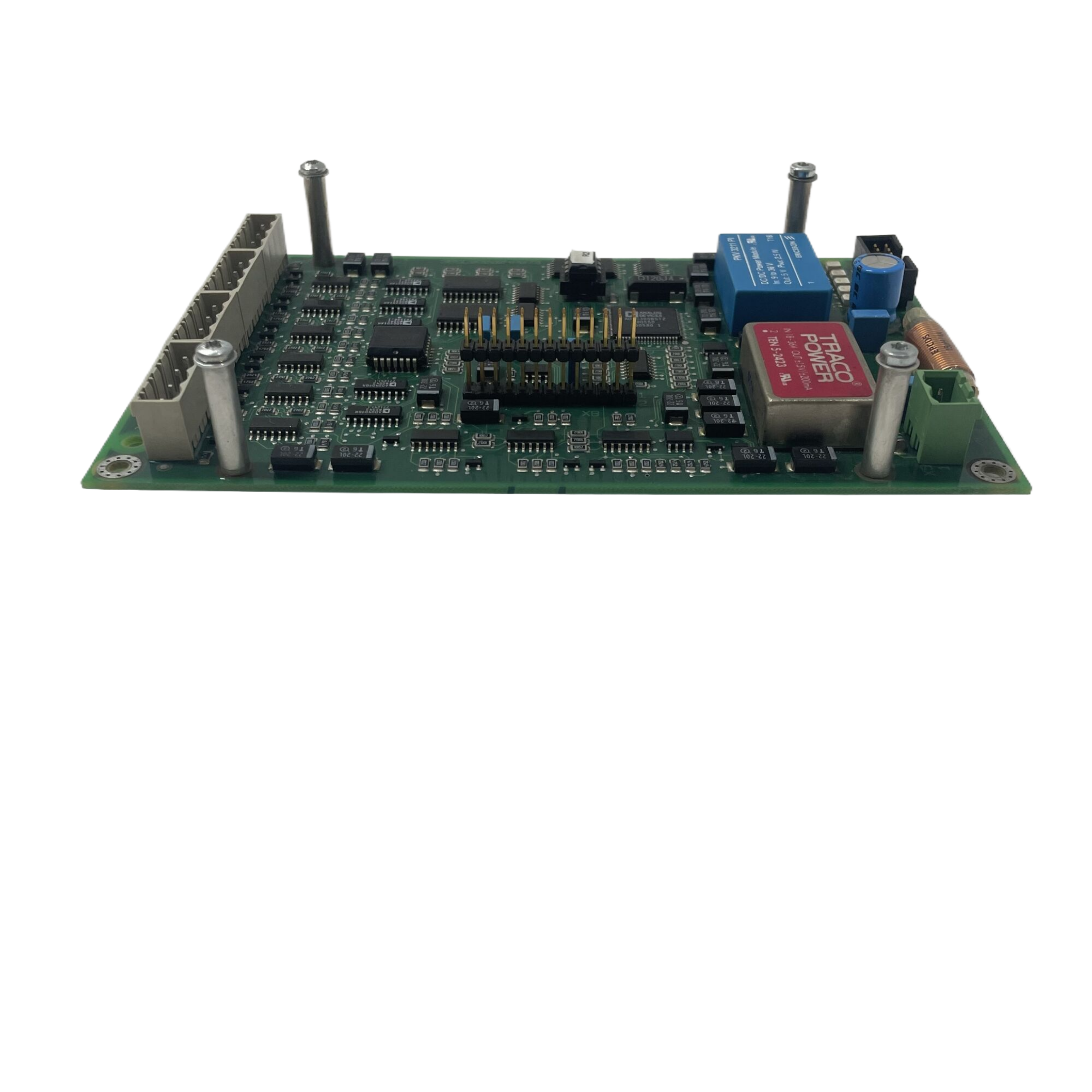

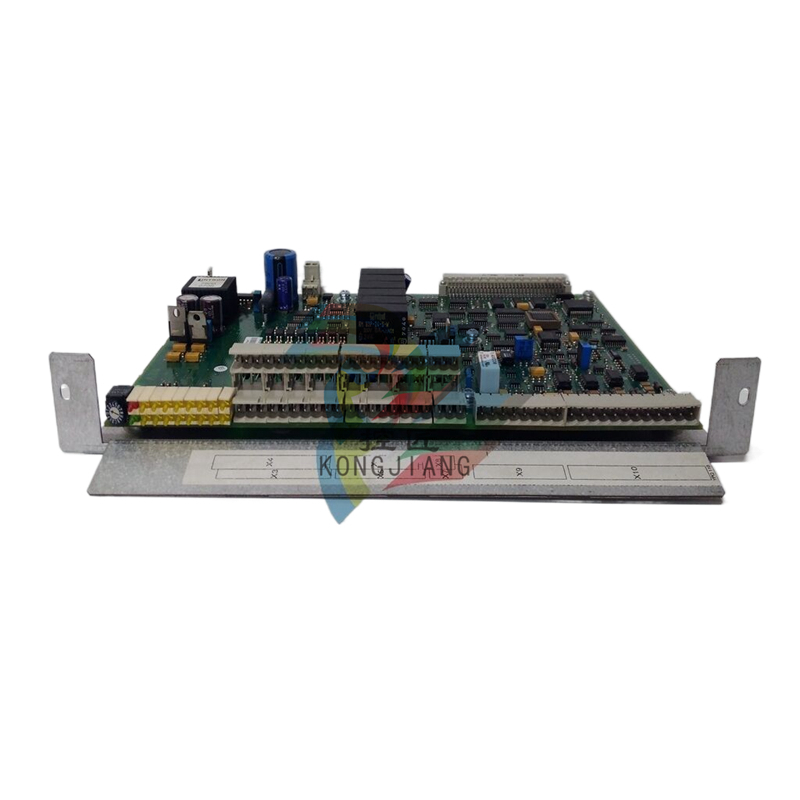

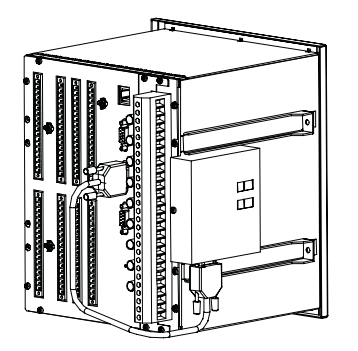

Construction and installation

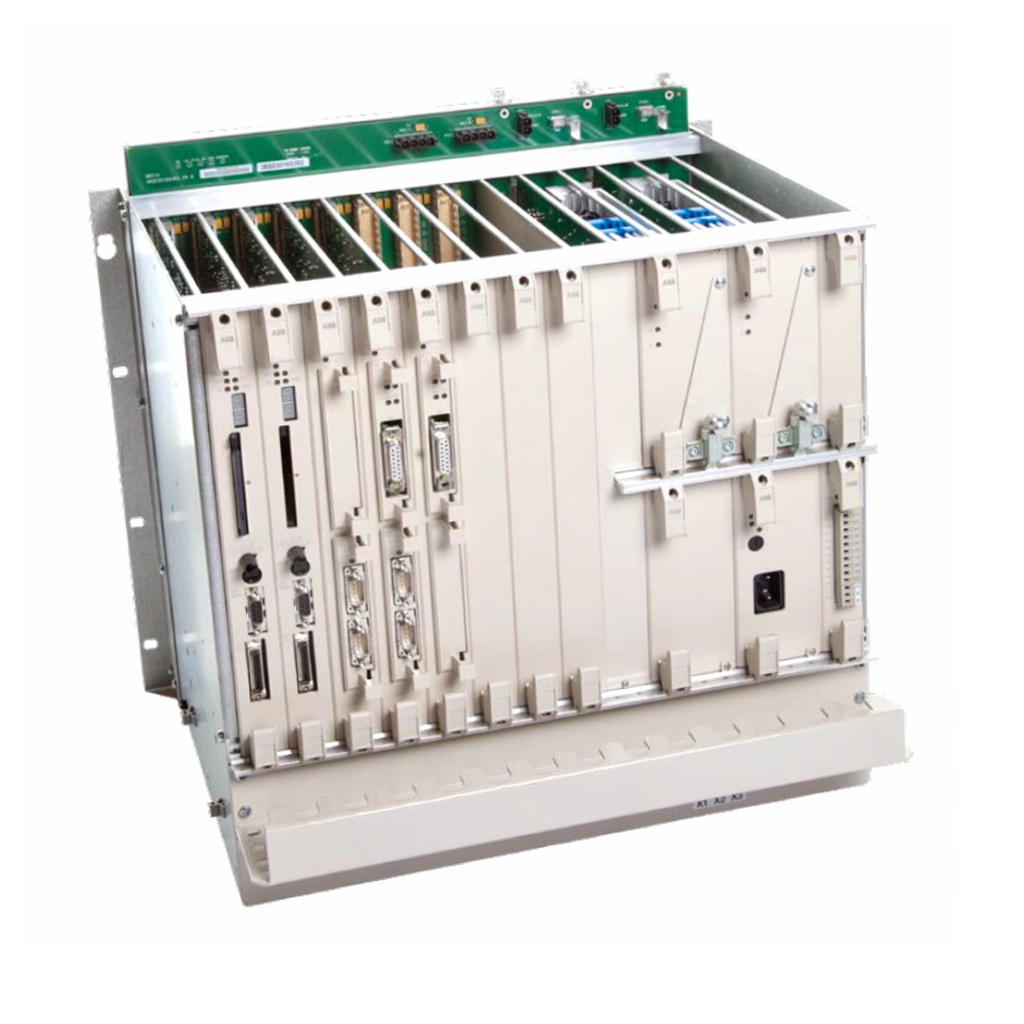

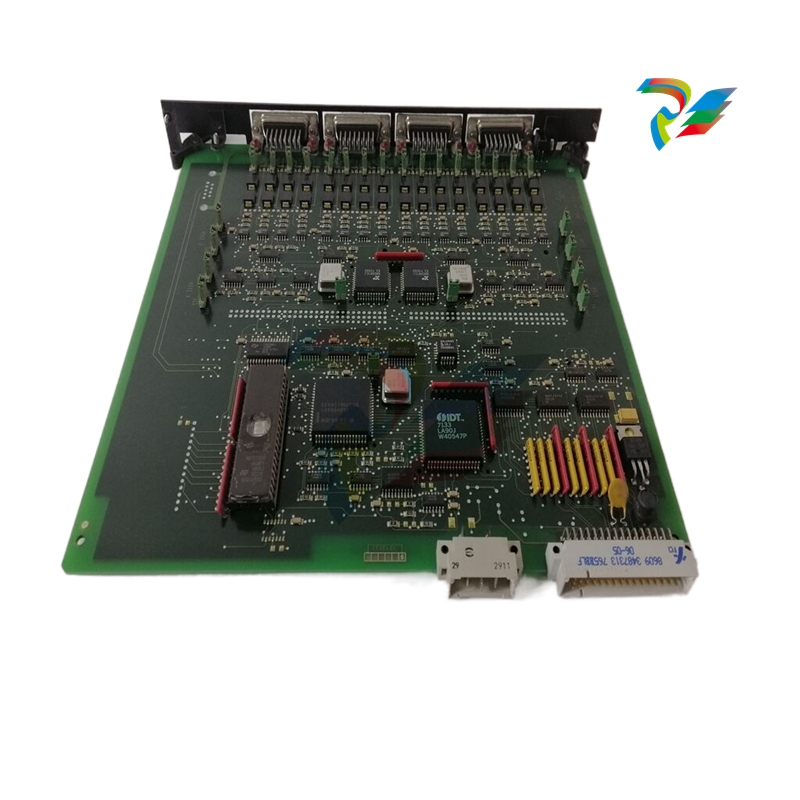

The RER 133 module is mounted on the side of the RE_ 54_ host device and is

connected by the supplied cable to the 9-pin female type D-connector (X3.2) of the

RE_ 54_ host device.

A050316

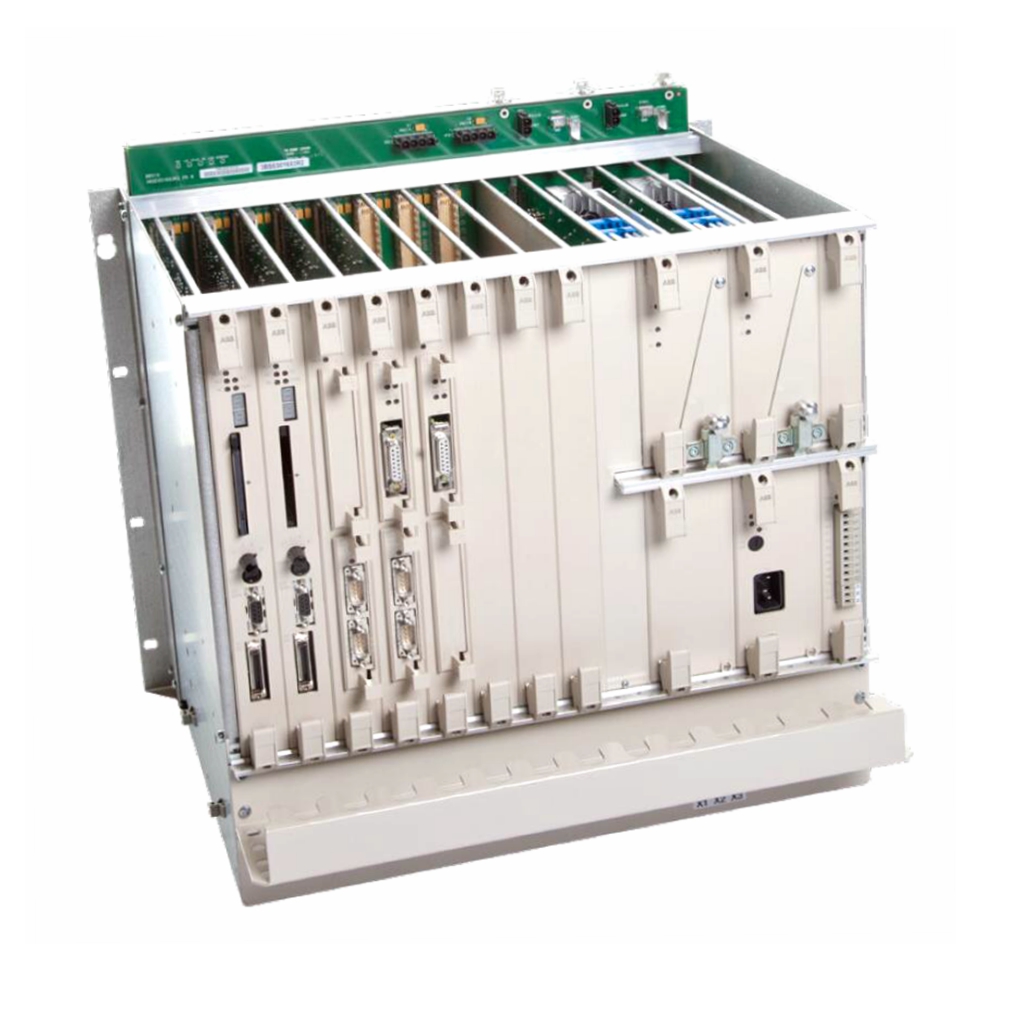

Fig. 5.-1 RER 133 mounted on a REF 54_ host device

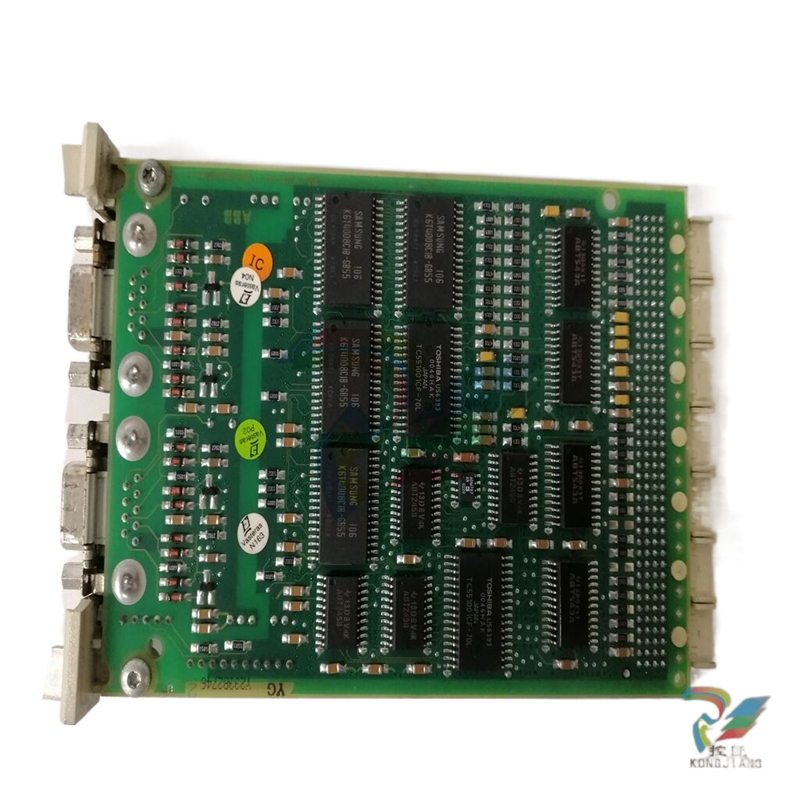

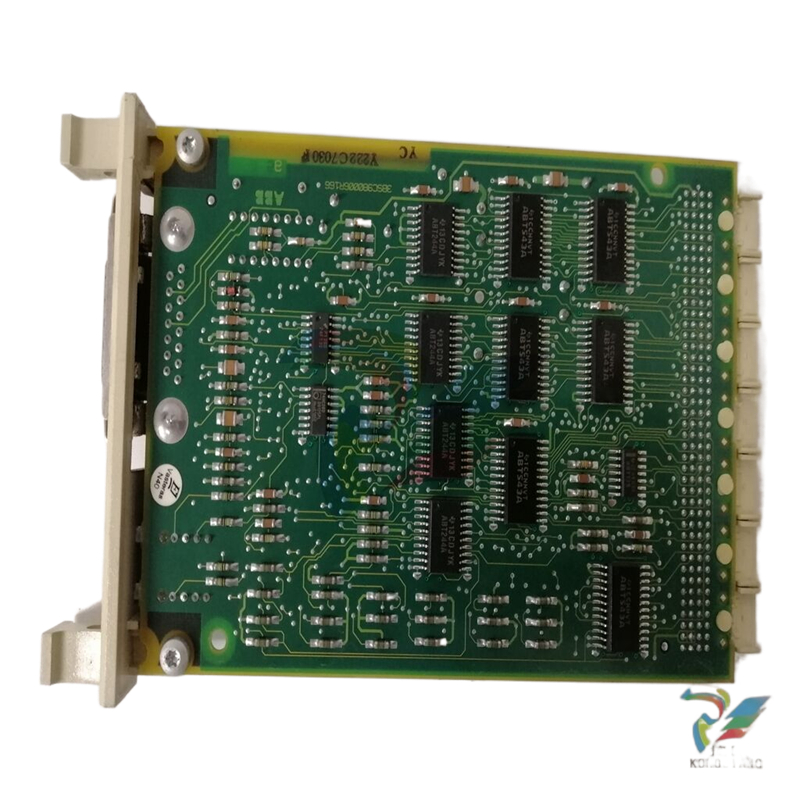

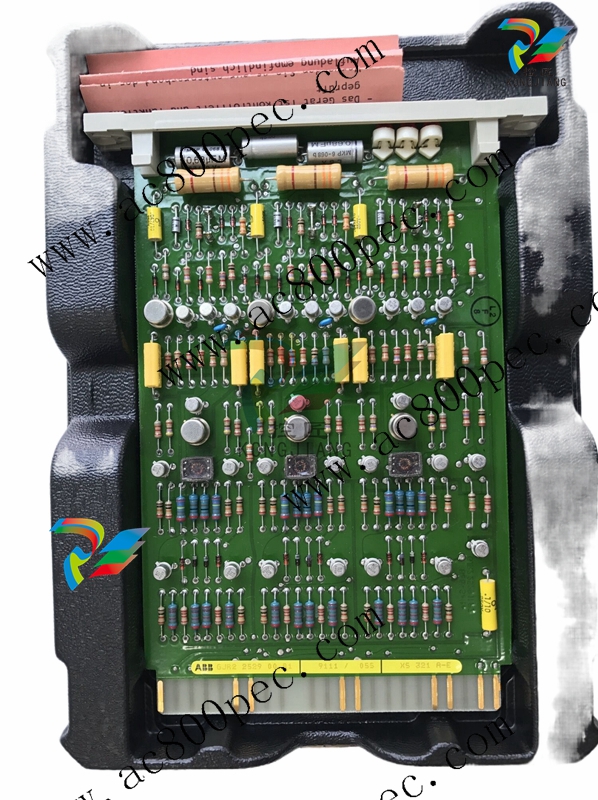

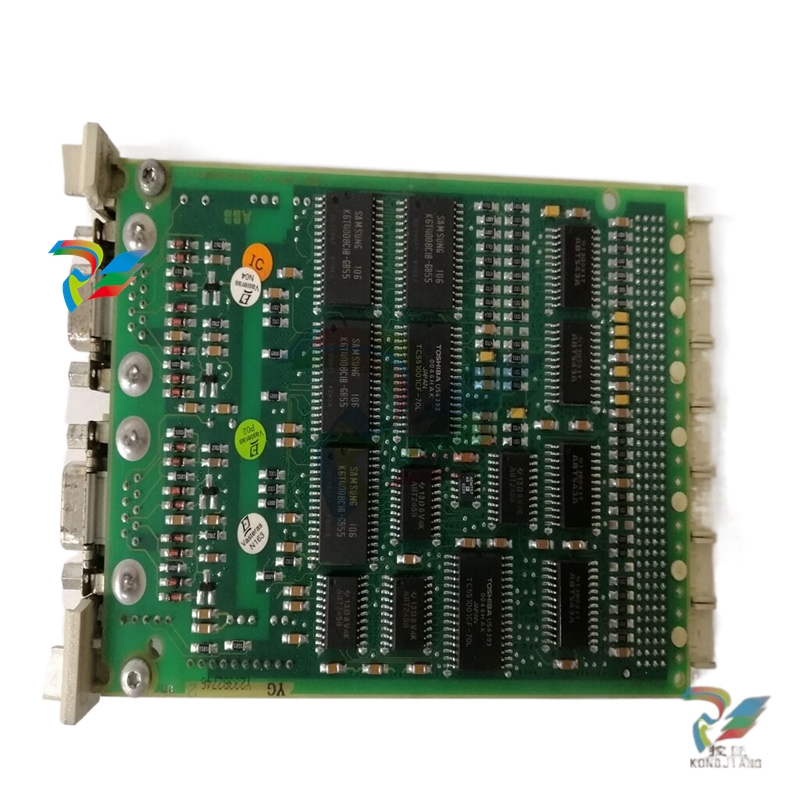

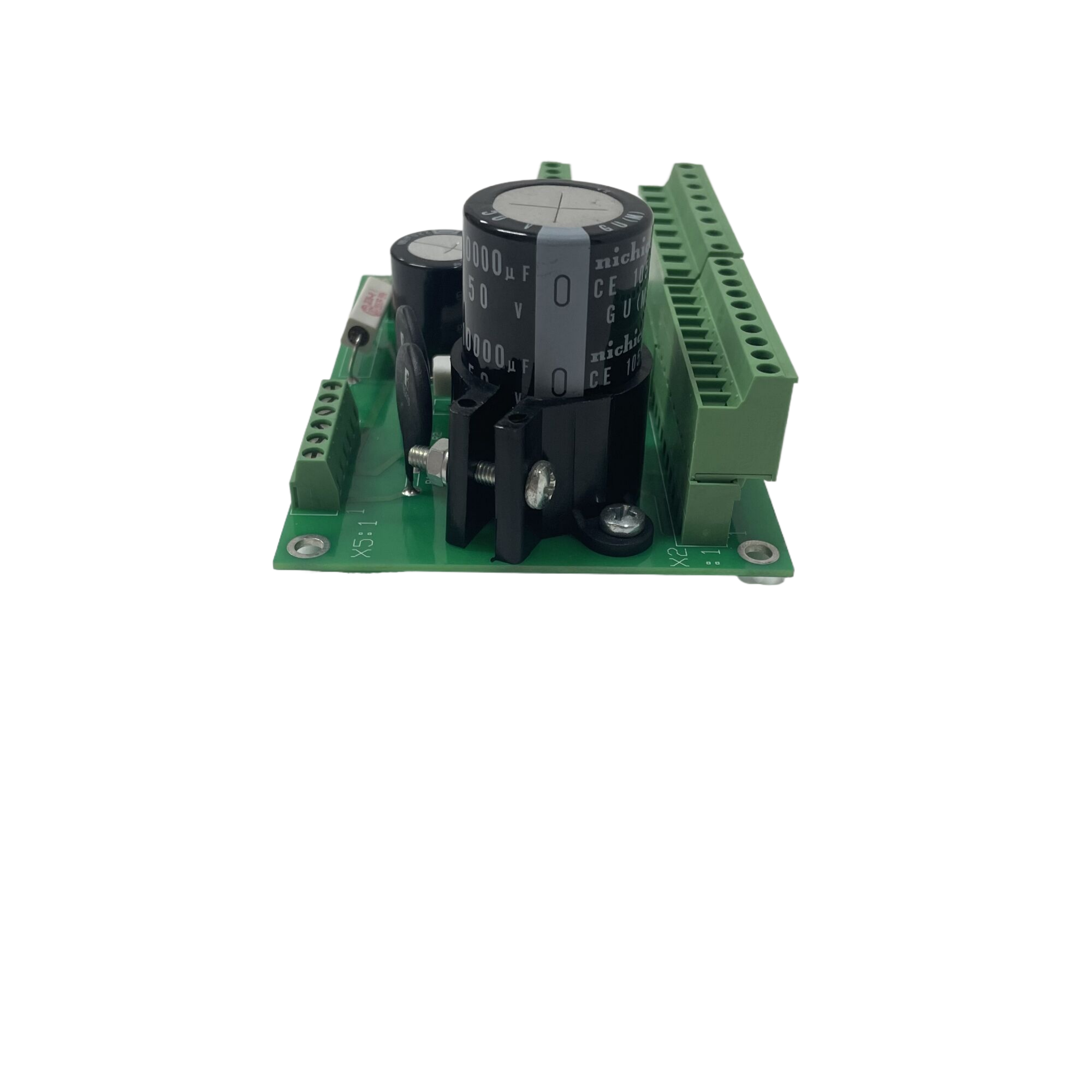

The RER 133 module consists of a printed circuit board and is housed in a metal

case. Because shielded cables and an RS-485 interface is used, special attention

must be paid to the grounding.

The dimensions of the case are: 95 mm x 101 mm x 30 mm (95 mm x 105 mm x 38

mm with mounting bracket)

Interfaces

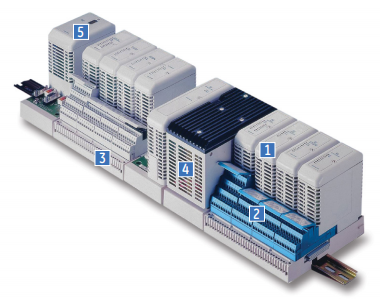

The RS-485 bus used by SPA, Modbus and DNP 3.0 requires a daisy chain topology.

A daisy chain topology means a node-to-node connection, where nodes are chained

using cables of minimal length. The cables must be point to point, no stars, rings or

other topologies are allowed. The bus must be terminated at both ends using 120Ω

resistors. The RER 133 includes as an option the use of internal termination

resistors. These resistors are enabled through DIP switch S2.

Pull-up and pull-down resistors must be used in one of the nodes, in order for the

receivers to be able to determine the state of the bus when it is idle. These resistors

can be enabled through DIP switch S2.

Please see sections ìModule configurationî on page 9 and ìConfiguration

examplesî on page 10 for the correct settings.

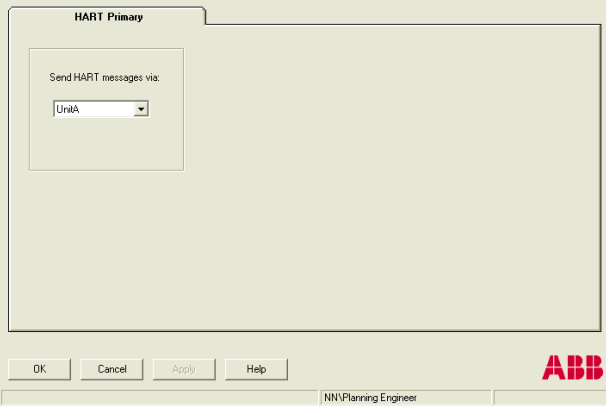

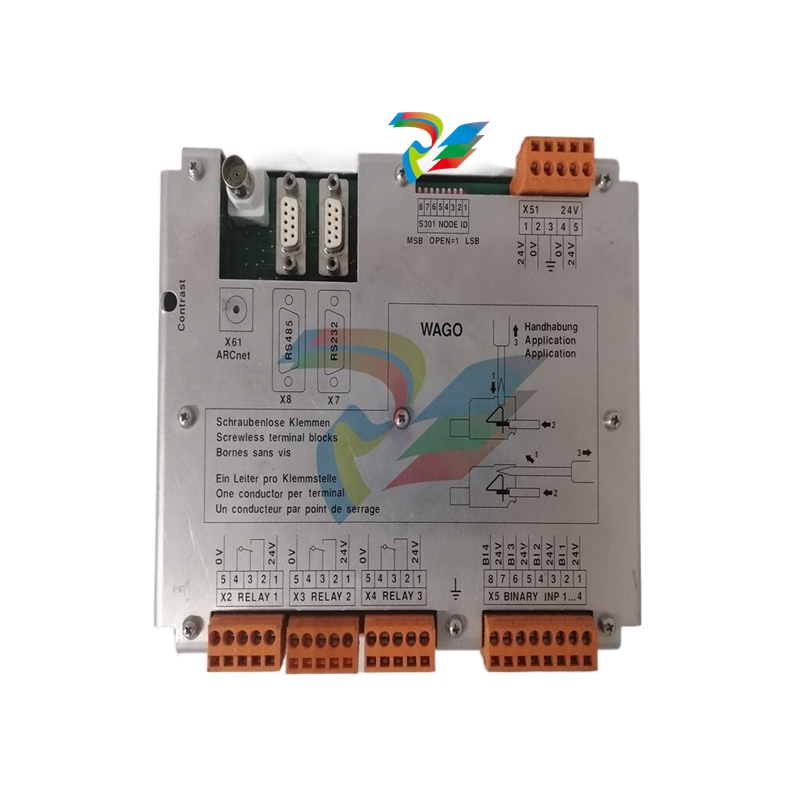

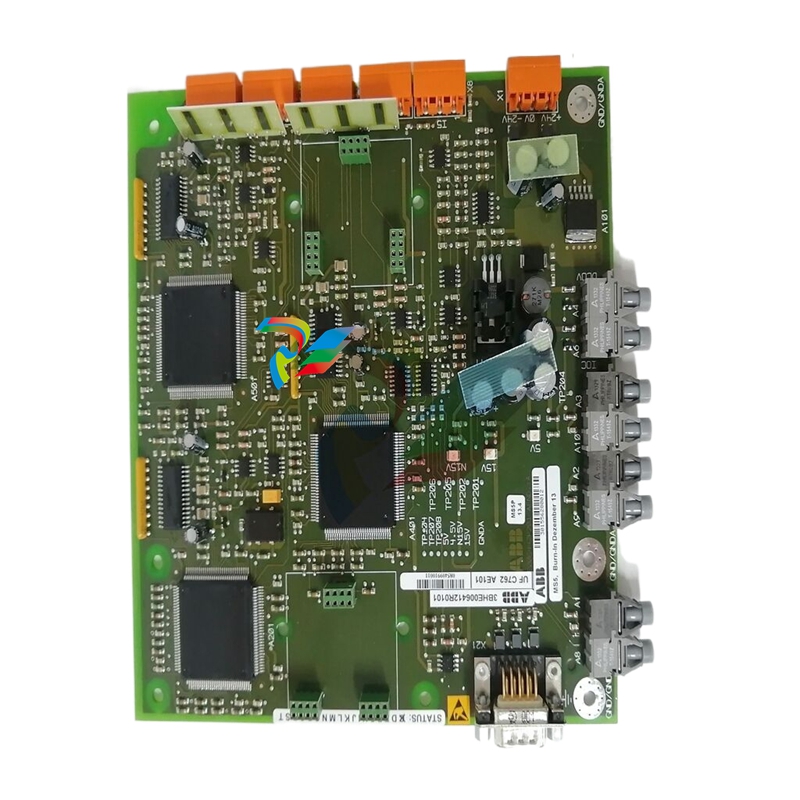

The RS-232 interface (X1) of the RER 133 module is shown in Fig. 6.-1.

Fig. 6.-1 Pin usage table for the 9-pin D-type connector (X1)

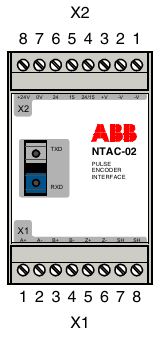

The RS-485 interface of the RER 133 module is shown in Fig. 6.-2. The connector

(X2) is an 8-pin Weidm¸ller terminal block. If GND (pin 5) is used, then it is

required for all other nodes to be isolated as well.

Fig. 6.-2 Pin usage table for the Weidm¸ller terminal block (X2)

1) used for Tx in 4-wire connection

2) used for Rx in 4-wire connection

Pin Usage

1 Not connected

2 TX

3 RX

4 +15 V DC, power supply for the RER 133 module

5 GND, signal ground for power supply

6 DSR (CD/CS)

7 RTS

8 Not connected

9 Not connected A050323

Pin Signal Functionality

1 Shield GND Can be used for cable shield

grounding

2 Shield GND C Can be used for cable shield

grounding via a capacitator

3 NC Not connected

4 AGND Can be used for potential

balancing between RS-485 nodes

5 B- Differential signal B (-) 1)

6 A+ Differential signal A (+) 1)

7 B- 4-wire differential signal B (-) 2)

8 A+ 4-wire differential signal A (+) 2)

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|