K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

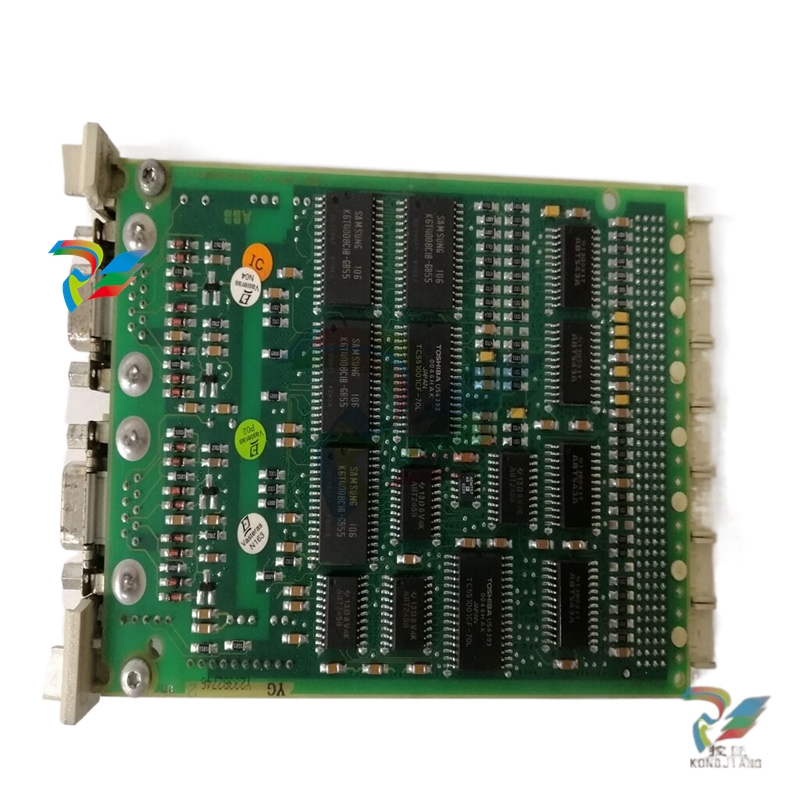

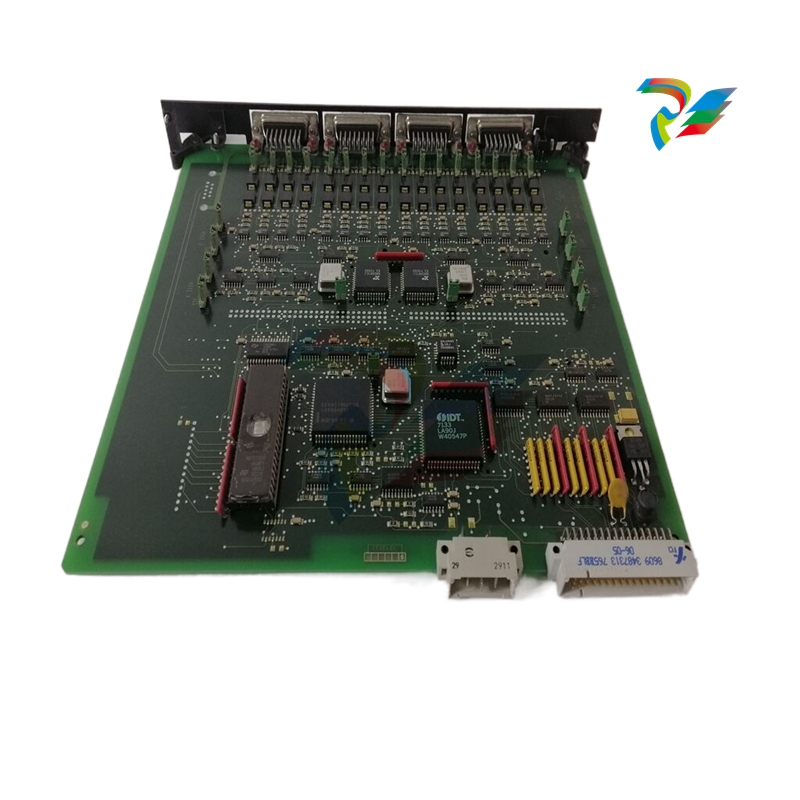

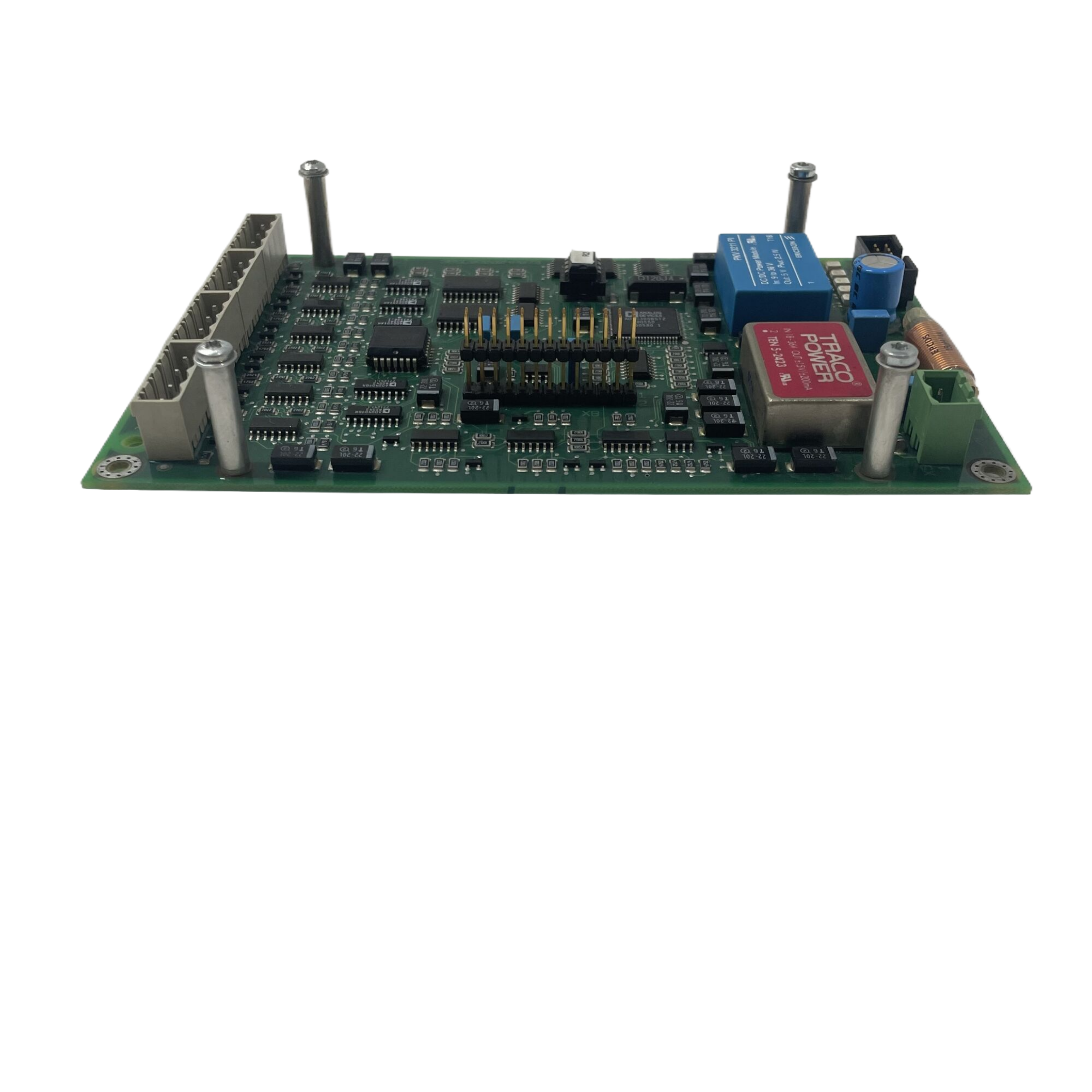

The Analog Output Module with 4 isolated outputs is an intelligent

module that controls to up to 4 analog devices.

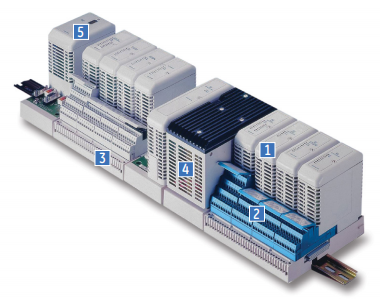

GE IC200ALG331 Analog Output Module

In current mode, a separate power supply may be required for

isolated inputs.

Module features include:

Four isolated 4-20mA current output channels

Software configuration, no jumpers or switches

Sixteen bit converter resolution

High accuracy factory calibration

The following features are software-configurable:

Per-channel selection of 4-20mA current or +/–10V voltage outputs

Selection of default/hold last state operation

Per-channel selection of default values

Per-channel selection of under-range and over-range

diagnostics levels

Per-channel selection of alarm levels

Per-channel scaling

Field re-calibration on command

Host Interface_______________________________________

The module receives 4 words of analog output data from the system.

Diagnostics ________________________________________

The module reports High/Low Limit, Over/Underrange, Open Wire,

Loss of Field Power Supply, and Non-volatile memory fault

diagnostics.

LED Indicators ______________________________________

The green FLD PWR LED indicates the presence of both logic

power and field power for the analog field-side circuits. It does not

indicate the presence of other supplies such as current loop supplies

on output points. The absence of either backplane or field power

turns off the FLD PWR LED.

The OK LED indicates module status:

On green indicates normal operation.

Flashing green indicates boot mode or update

Flashing amber indicates self-diagnostic error.

Off indicates no 3.3V power

Note that this module is the only one that has its OK LED located

before the FLD PWR LED in the A slot.

Module Characteristics

Channels 4 outputs

Module ID FFFF9805

Isolation:

User input to logic (optical)

and to frame ground,

Group to Group

Channel to channel

250VAC continuous; 1500VAC for 1 minute

Not applicable

250VAC continuous; 1500VAC for 1 minute

LED indicators FLD PWR LED indicates the presence of both logic

power and user power. OK LED indicates module

status.

Backplane current

consumption

5V output: 10mA maximum.

3.3V output: 115mA maximum

Configuration parameters Output default

External power supply:

Range

Current consumption

+18 to +30VDC including ripple

100mA maximum plus load currents

Thermal derating None

Diagnostics High/Low Limit, Over/Underrange, Open Wire, Loss of

Field Power Supply, Non-volatile memory fault

Output Characteristics

Output operating range Current mode: +1 to 20mA

Voltage mode: +/-10VDC

Accuracy at 25 degrees C +/- 0.1% maximum of full scale

Temperature coefficient Current mode: 45ppm/°C typical, 90 ppm/°C maximum

Voltage mode: 30ppm/°C typical, 60 ppm/°C maximum

Load characteristics Current mode: 0 to 1250 ohms

Voltage mode: 2K ohms minimum

Analog Resolution (1LSB) Current mode: 381 nA nominal

Voltage mode: 381 µV nominal

Update rate 7mS maximum

Channel-to-channel

crosstalk rejection

70dB minimum

Output default Hold Last State (default)

0 (configurable)

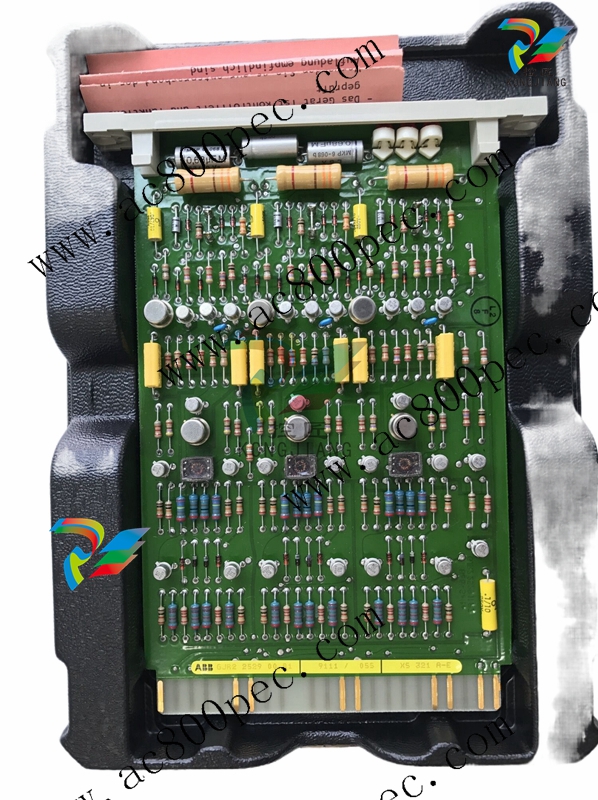

Preinstallation Check

Carefully inspect all shipping containers for damage. If any equipment is

damaged, notify the delivery service immediately. Save the damaged

shipping container for inspection by the delivery service. After unpacking

the equipment, record all serial numbers. Save the shipping containers

and packing material in case it is necessary to transport or ship any part

of the system.

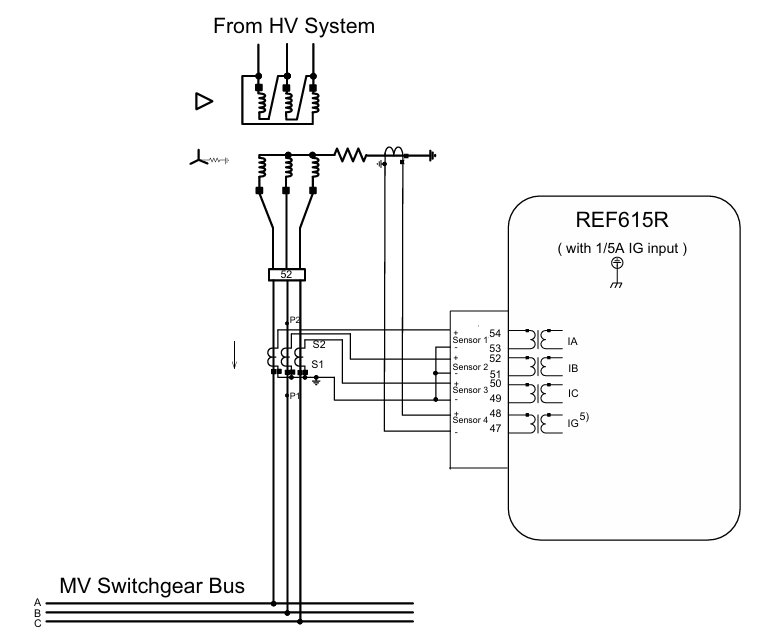

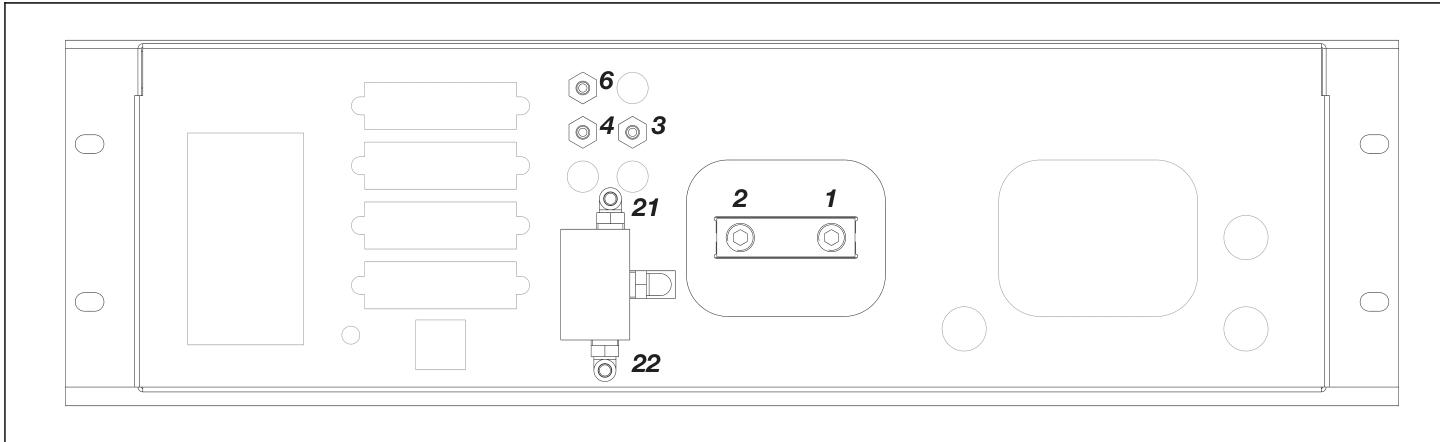

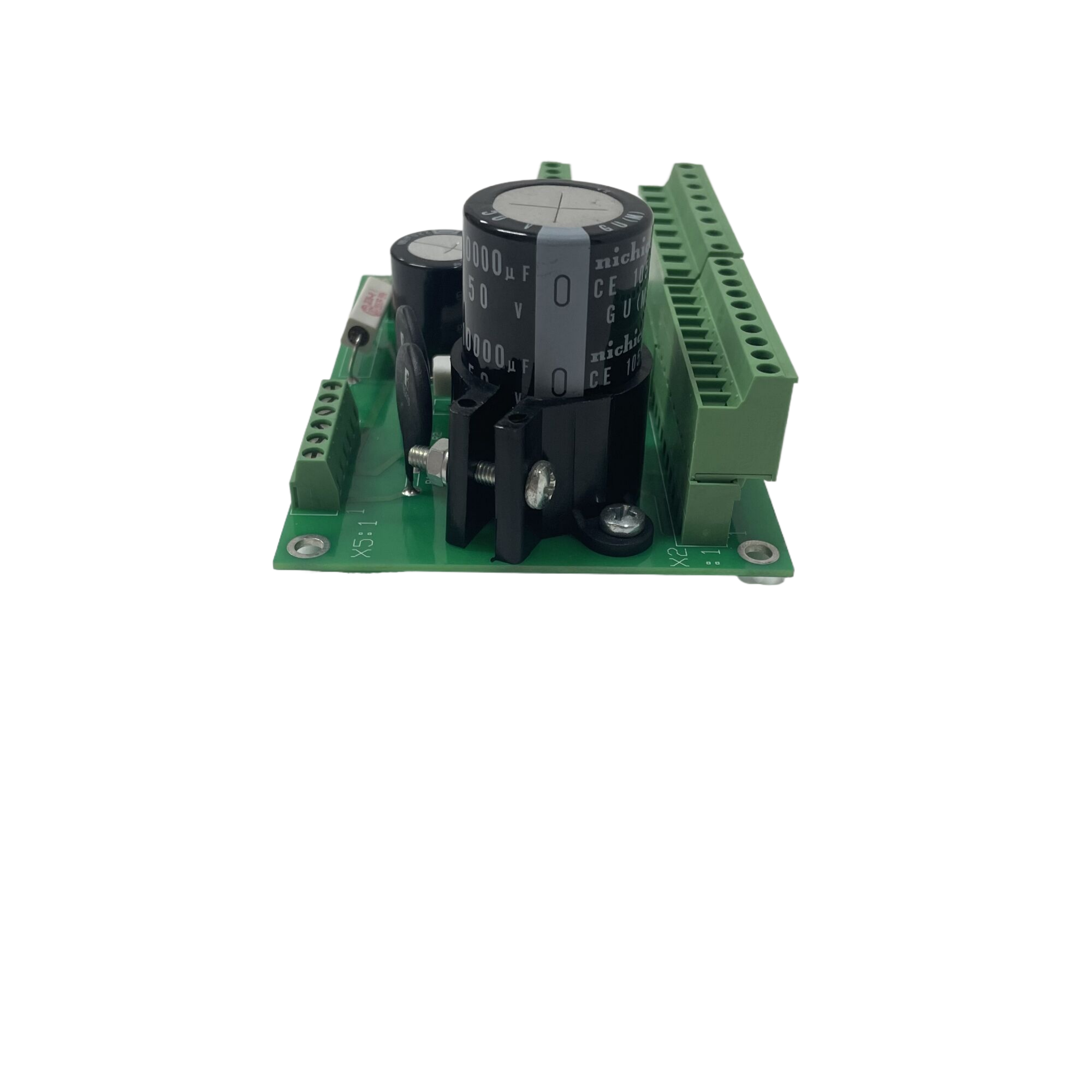

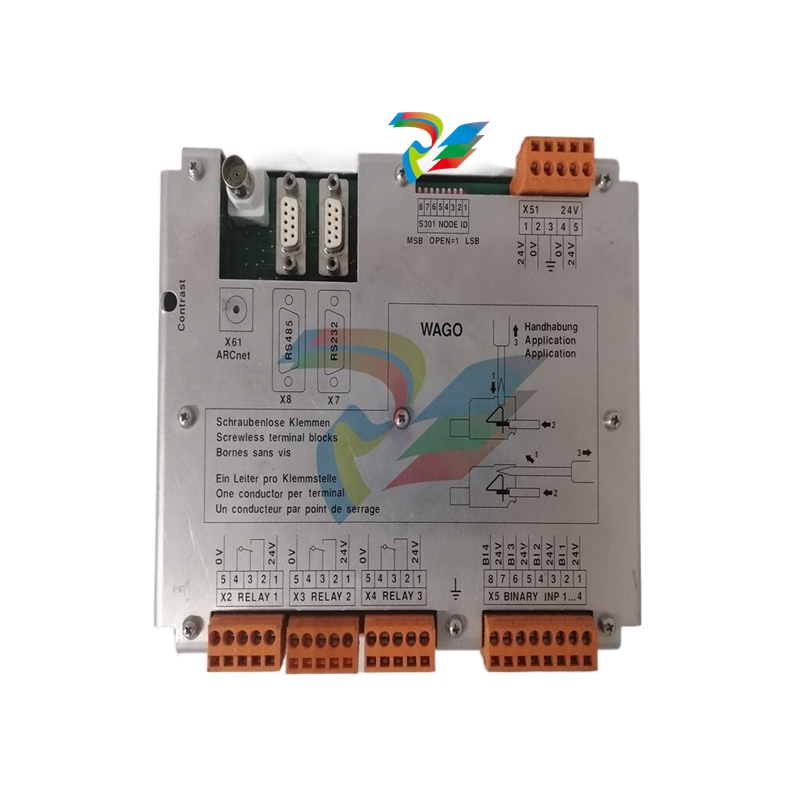

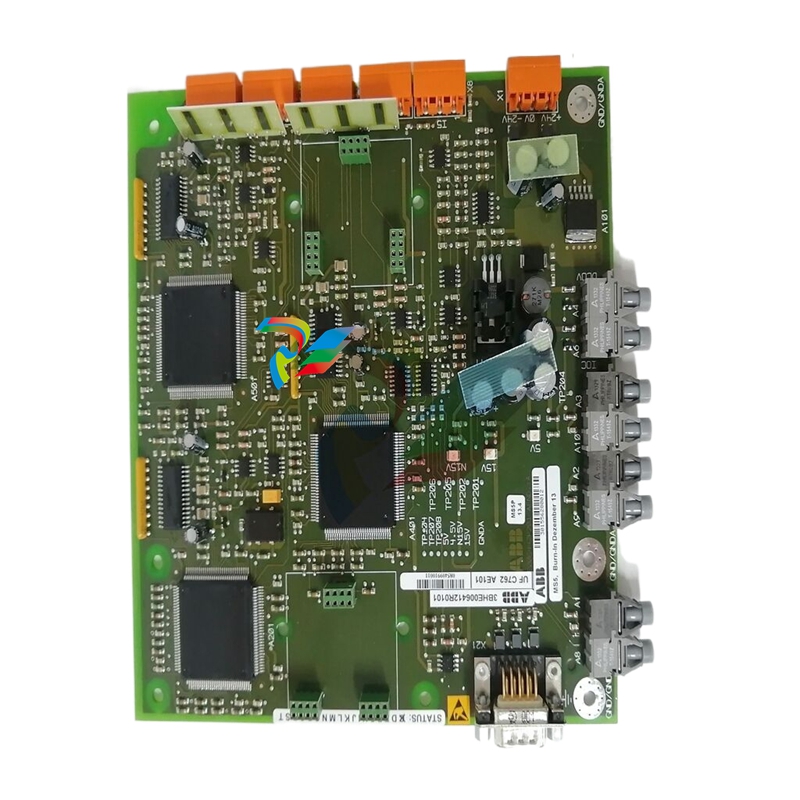

Field Wiring Terminals

Terminal assignments for the module are shown below.

Number Connection Number Connection

A1 No connection B1 I1+

A2 Shield Ground B2 I1-

A3 No connection B3 V1+

A4 Shield Ground B4 V1-

A5 No connection B5 I2+

A6 Shield Ground B6 I2-

A7 No connection B7 V2+

A8 Shield Ground B8 V2-

A9 No connection B9 I3+

A10 Shield Ground B10 I3-

A11 No connection B11 V3+

A12 Shield Ground B12 V3-

A13 No connection B13 I4+

A14 Shield Ground B14 I4-

A15 No connection B15 V4+

A16 Shield Ground B16 V4-

A17 No connection B17 DC -

A18 No connection B18 DC+

A 24 volt power supply must be connected to B17 and B18 to

operate the module.

Voltage outputs are powered from the module. For each channel, V+

is positive with respect to V- when the channel’s output data is

positive.

Current outputs act as current regulators and require a supply to

power the load. The current loop can be connected either as a

current source or as a current sink to the load.

The loads are isolated if the loop supply is isolated. However, if the

module supply is also used as the loop supply, the loads are not

isolated.

Wiring Connections for Carriers with Two Rows of Terminals

Shielded twisted pair cable is recommended for the analog channel

connections.

If the module is installed on a Terminal-style I/O Carrier or a Compact

Terminal-style I/O Carrier, the cable shield can be connected directly to

the carrier.

If the module is installed on a Connector-style I/O Carrier, the cable

shield can be connected directly to an Interposing Terminal. A shielded

interposing cable (shielded cables are available separately) must be

used between the Connector-style I/O Carrier and the Interposing

Terminal.

An Auxiliary I/O Terminal Strip can also be added to the Interposing

Terminal if additional shield connections are required.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information