K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

Risk of injury!

The device includes slot sensors with sharp edges.

• Adjust the metal tags using a screwdriver only!

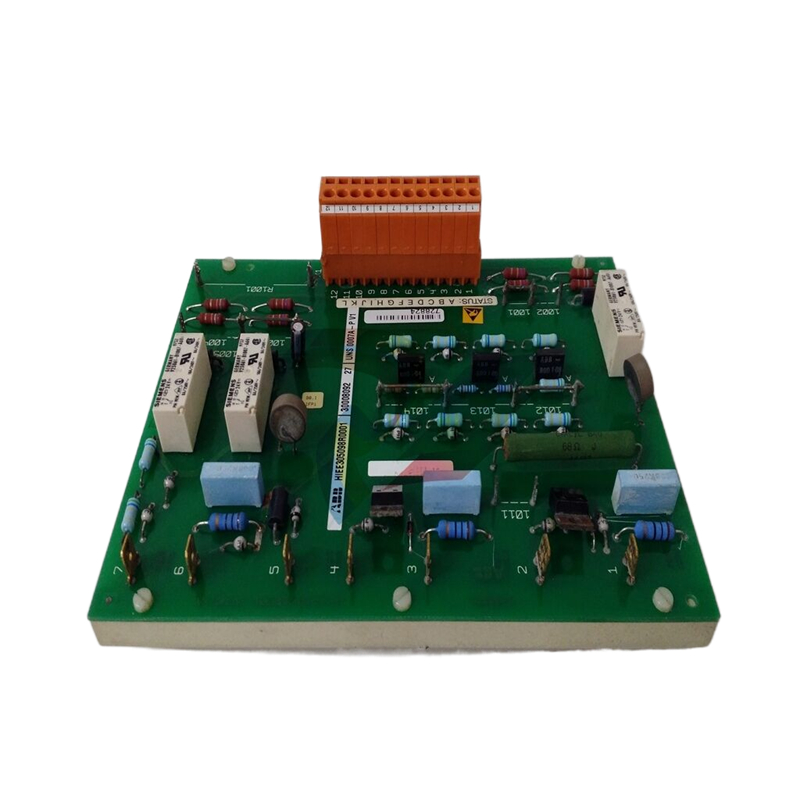

ABB 07KT98 GJR5253100R0278 Programmable Processor Unit

switches

1. Loosen the screws for the housing cover and remove it.

CAUTION

Risk of injury!

The device includes slot sensors with sharp edges.

• Adjust the metal tags using a screwdriver only!

2. Set the upper and lower switching points for binary feedback

as follows:

• Select the ‘Manual Adjustment’ operating mode and move

the final control element by hand into the lower switching

position.

• Using a screwdriver, adjust the metal tag of proximity

switch 1 (lower contact) on the axis until contact is made,

i. e., just before it is inserted in the proximity switch. The

slot sensor enters proximity switch 1 when the feedback

shaft is rotated clockwise (as viewed from the front).

• Move the final control element by hand into the upper

switching position.

• Using a screwdriver, adjust the metal tag of proximity

switch 2 (upper contact) on the axis until contact is made,

i. e., just before it is inserted in the proximity switch. The

slot sensor enters proximity switch 2 when the feedback

shaft is rotated counter-clockwise (as viewed from the

front).

3. Attach the housing cover and screw it onto the housing.

4. Tighten the screws so that they are hand-tight.

Setting the mechanical limit switch with 24 V

microswitches

1. Loosen the screws for the housing cover and remove it.

2. Select the ‘Manual Adjustment’ operating mode and move

the final control element by hand into the desired switching

position for contact 1.

3. Set maximum contact (1, lower washer).

Fasten the upper washer with the special adjustment

retainer and rotate the lower washer manually.

4. Select the ‘Manual Adjustment’ operating mode and move

the final control element by hand into the desired switching

position for contact 2.

5. Set minimum contact (2, upper washer);

Fasten the lower washer with the special adjustment retainer

and rotate the upper washer manually.

6. Connect the microswitch.

7. Attach the housing cover and screw it on to the housing.

8. Tighten the screws so that they are hand-tight.

7 Operation

Safety instructions

CAUTION

Risk of injury due to incorrect parameter values!

Incorrect parameter values can cause the valve to move

unexpectedly. This can lead to process failures and result in

injuries.

• Before recommissioning a positioner that was previously

in use at another location, always reset the device to its

factory settings.

• Never start automatic adjustment before restoring the

factory settings!

If there is a chance that safe operation is no longer possible,

take the device out of operation and secure it against

unintended startup.

Parameterization of the device

The LCD display features operating buttons which enable the

device to be operated with the housing cover open.

Menu navigation

M10980

1 Value display with unit

2 Symbol display

3 Designator display

4 Operating buttons for menu

navigation

Figure 24: LCD display with operating buttons

Value display with unit

This 7-segment display with four digits indicates parameter

values or parameter reference numbers. For values, the physical

unit (°C, %, mA) is also displayed.

Designator display

This 14-segment display with eight digits indicates the

designators of the parameters with their status, of the

parameter groups, and of the operating modes.

Description of symbols

Symbol Description

Operation or access is restricted.

Control loop is active.

The symbol is displayed when the positioner is in operating

mode 1.0 CTRL_ADP (adaptive control) or 1.1 CTRL_FIX (fixed

control) at operating level. On the configuration level there are

test functions for which the controller will be active as well. The

control loop symbol will also be displayed when these functions

are active.

Manual adjustment.

The symbol is displayed when the positioner is in operating

mode 1.2 MANUAL (manual adjustment within the stroke range)

or 1.3 MAN_SENS (manual adjustment within the measuring

range) at operating level. At configuration level, manual

adjustment is active when setting the valve range limits

(parameter group 6 MIN_VR (min. of valve range) and 6 MAX_VR

(max. of valve range)). The symbol will also be displayed when

these parameters are being set.

The configuration icon indicates that the positioner is at the

configuration level. The control operation is inactive.

The four operating buttons ENTER, MODE, and are pressed

individually or in certain combinations according to the function

desired.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information