K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

The information in this document has been carefully checked and is believed to be entirely reliable. While all

reasonable efforts to ensure accuracy have been taken in the preparation of this manual, GE Fanuc Embedded Systems

assumes no responsibility resulting from omissions or errors in this manual, or from the use of information contained herein.

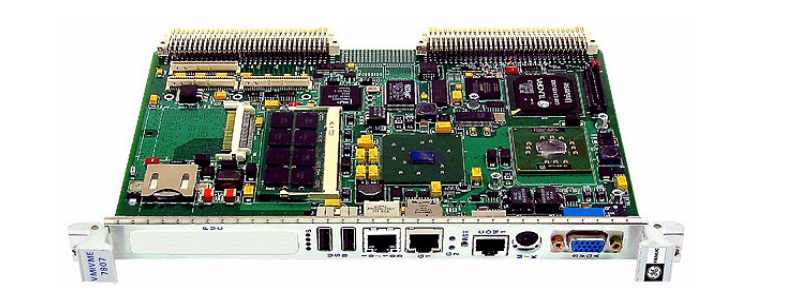

GE VMIVME-7807 M-Based VME SBC

IntroductionGE Fanuc Embedded Systems’ VMIVME-7807/VME-7807RC are full featured

Pentium® M-based, single board computers (SBCs) in a single-slot, passively cooled,

VME Eurocard form factor. These products utilize the advanced technology of Intel®’s

855GME chipset.

The VMIVME-7807/VME-7807RC provide features typically found on desktop

systems such as:

• 1.0GB DDR SDRAM using one SODIMM and an optional 512MB of solder-in

memory for a maximum of 1.5GB

• Built-in SVGA support (front panel connection)

• Digital video controller (rear I/O) DVI-D with dual head display capabilities

• 10/100 Mbit Ethernet controller (front panel connection)

• Dual Gigabit Ethernet supporting (front panel or rear I/O)

• Optional P0 with VITA 31.1 interface

• Serial ATA (SATA) support (rear I/O)

• Serial port COM1 (front panel connection)

• Ultra IDE drive support (rear I/O)

• Real-Time clock/calendar

• Front panel reset switch

• Miniature speaker

• Keyboard/Mouse port (front panel connection)

The 855GME chipset allows the VMIVME-7807/VME-7807RC to provide enhanced

features such as integrated video and Ultra ATA/100 IDE support. The

VMIVME-7807/VME-7807RC are capable of executing many of today’s desktop

operating systems such as Microsoft®’s Windows® XP, Windows 2000 and a wide

variety of Linux® based operating systems. The standard desktop features of the

VMIVME-7807/VME-7807RC are described in Chapter 2 of this manual.

The VMIVME-7807/VME-7807RC provide features useful to embedded applications

such as:

• Three serial ports: COM2, COM3 and COM4 (rear I/O)

• Four USB 2.0 ports (two on front panel and two rear I/O)

• 32KB of nonvolatile RAM

• Remote Ethernet booting

• Up to 2GB of CompactFlash on secondary IDE (optional)

• Software-selectable Watchdog Timer with reset

Additionally, the VMIVME-7807/VME-7807RC offer one PMC expansion site (PCI-X,

66MHz) with front panel access. The VMIVME-7807/VME-7807RC are capable of

executing many of today’s operating systems such as VxWorks®, Solaris™ or QNX®.

The embedded features of the VMIVME-7807/VME-7807RC are described in

Chapter 3 of this manual.

The VMIVME-7807/VME-7807RC are suitable for use in applications ranging from

telecommunications, simulation, instrumentation, industrial control, process control

and monitoring, factory automation, automated test systems, data acquisition

systems and anywhere that the highest performance processing power in a single

VME slot is desired.

Intel 855GME Chipset

The VMIVME-7807/VME-7807RC incorporate the latest Intel chipset technology, the

855GME. This chipset utilizes Advanced Hub Architecture (AHA). The AHA allows

for increased system performance by separating many high-bandwidth I/O accesses

from PCI accesses, relieving bottlenecks on the PCI bus. Furthermore, the 855GME

chipset brings new levels of integration to motherboard chipsets and provides

additional features such as Integrated LVDS and Serial ATA

Organization of the Manual

This manual is composed of the following chapters and appendices:

Chapter 1 - Installation and Setup describes unpacking, inspection, hardware jumper

settings, connector definitions, installation, system setup and operation of the

VMIVME-7807/VME-7807RC .

Chapter 2 - Standard Features describes the unit design in terms of the standard PC

memory and I/O maps, along with the standard interrupt architecture.

Chapter 3 - Embedded PC/RTOS Features describes the unit features that are beyond

standard functions.

Maintenance provides information relative to the care and maintenance of the unit.

Compliance provides applicable information regarding regulatory compliance.

Appendix A - Connector Pinouts illustrates and defines the connectors included in the

unit’s I/O ports.

Appendix B - AMI BIOS Setup Utility describes the menus and options associated

with the AMI (system) BIOS.

Appendix C - Argon BIOS describes the menus and options associated with the LAN

Boot BIOS.

Appendix D - System Driver Software describes the steps required to load system

drivers.

Safety Summary

The following general safety precautions must be observed during all phases of the

operation, service, and repair of this product. Failure to comply with these

precautions or with specific warnings elsewhere in this manual violates safety

standards of design, manufacture, and intended use of this product.

GE Fanuc Embedded Systems assumes no liability for the customer's failure to

comply with these requirements.

Ground the System

To minimize shock hazard, the chassis and system cabinet must be connected to an

electrical ground. A three-conductor AC power cable should be used. The power

cable must either be plugged into an approved three-contact electrical outlet or used

with a three-contact to two-contact adapter with the grounding wire (green) firmly

connected to an electrical ground (safety ground) at the power outlet.

Do Not Operate in an Explosive Atmosphere

Do not operate the system in the presence of flammable gases or fumes. Operation of

any electrical system in such an environment constitutes a definite safety hazard.

Keep Away from Live Circuits

Operating personnel must not remove product covers. Component replacement and

internal adjustments must be made by qualified maintenance personnel. Do not

replace components with power cable connected. Under certain conditions,

dangerous voltages may exist even with the power cable removed. To avoid injuries,

always disconnect power and discharge circuits before touching them.

Do Not Service or Adjust Alone

Do not attempt internal service or adjustment unless another person, capable of

rendering first aid and resuscitation, is present.

Do Not Substitute Parts or Modify System

Because of the danger of introducing additional hazards, do not install substitute

parts or perform any unauthorized modification to the product. Return the product

to GE Fanuc Embedded Systems for service and repair to ensure that safety features

are maintained.

Dangerous Procedure Warnings

Warnings, such as the example below, precede only potentially dangerous procedures

throughout this manual. Instructions contained in the warnings must be followed.

WARNING: Dangerous voltages, capable of causing death, are present in this system.

Use extreme caution when handling, testing, and adjusting

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923