K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

Data Log indicator/Data Log menu button.

Gray text when no data logging is occurring on the Control Station.

When data logging is occurring, the icon becomes colorful and the

text becomes black.

Honeywell 8 I/O Slot Rack 900R08-0200

Figure 5 Status bar

Button Description Function

1 Data Log indicator/Data Log menu button.

Gray text when no data logging is occurring on the Control Station.

When data logging is occurring, the icon becomes colorful and the

text becomes black.

Touch to go to Data Log

menu. See page 64.

2 Diagnostic indicator.

Gray text when there is no controller diagnostic present.

When a controller diagnostic is present, the button flashes.

Touch to go to System

Diagnostics page. See page

36.

3 Alarm indicator.

Gray text when there are no active alarms.

When there is an active alarm present (either acknowledged or

unacknowledged), the white background turns red and the icon

becomes colorful and the text becomes white.

When there are any unacknowledged alarms, the button flashes.

When all alarms become acknowledged, the flashing stops.

Touch to go to Alarms

console or Alarm Group

display depending on how the

Control Station was

configured (see Station

Designer manual section on

Alarms). Here all alarms are

displayed, with buttons that let

you mute and acknowledge

alarms.

Note: To see alarm history, go

to Alarm and Event Summary.

4 Event indicator/Alarm and Event Summary button.

Gray text when no event is present.

When an event occurs, a description appears in black text and the

background changes to a pale yellow.

Touch to go to Alarm and

Event Summary, where they

can be viewed or cleared.

5 Controller mode, time and date. Touch to go to Controller

Setup. See page 19.

6 Language of displayed text is indicated by flag icon. Touch to go to Language

Setup. See page 68

Status LEDs

The Status LEDs indicate:

• Run status of the Control Station

• CompactFlash card status

• Alarm status.

Figure 6 Status LEDs

Green LED Indication

Flashing Unit is in the boot loader, no valid configuration is loaded.

Steady Unit is powered and running an application.

Yellow LED Indication

Off No CompactFlash card present.

Steady CompactFlash card present.

Flashing rapidly CompactFlash being checked.

Flickering Unit is writing to the CompactFlash, either because it is storing data, or

because the PC connected via the USB port has locked the drive.

Flashing slowly Incorrectly formatted CompactFlash card present.

Red LED Indication

Flashing A tag is in alarm state.

Steady Valid configuration is loaded and no alarms are present.

USB Device

The USB Device port is for downloading a configuration from Station Designer to the Control Station.

Type B connector. Note: USB 3.0 support is only available on the 900CS10.

USB Host

USB Host Port A is for exporting data logs to a USB storage device with Type A connector.

USB Host Port B is not used.

Ethernet

The Ethernet port is for fastest communication with your HC900 Controller, PC, or other devices. Use an

Ethernet switch to link multiple devices.

RS485

The RS485 port is for communication with HC900 Controller if Ethernet is not desired or available.

RS232

The RS232 ports are not recommended due to reduced performance. Port B may be used to connect to

HC900. Port A PGM Port may be connected to your PC.

NOTE: The 15" model has two Ethernet ports and two RS485 ports whereas the 10" model has one of

each.

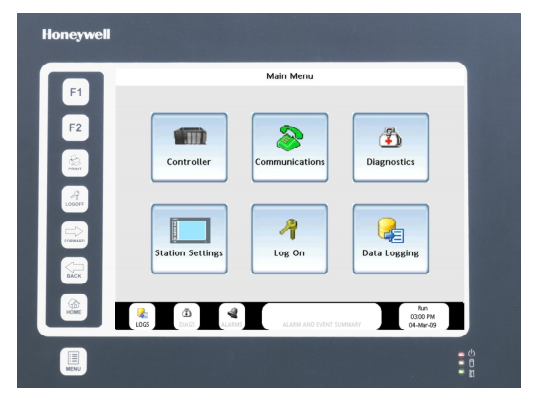

Figure 7 Main Menu

Functions

The Main Menu is for viewing and adjusting settings for your Control Station and HC900 Controller.

Process displays are accessed under the Home key.

Table 1 Main menu functions

Menu Item Function

Controller Controller status and setup.

Communications Controller communications. Serial ports, Ethernet ports, I/O, Modbus, Hosts,

Peers.

Diagnostics Diagnostic status of controller, I/O, communications.

Station Settings File management of CompactFlash and USB device. Adjust/calibrate/clean touch

screen. View status of communication ports. Set passwords.

Log On Security manager for logging on.

Data Logging File management of Data Logs.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923