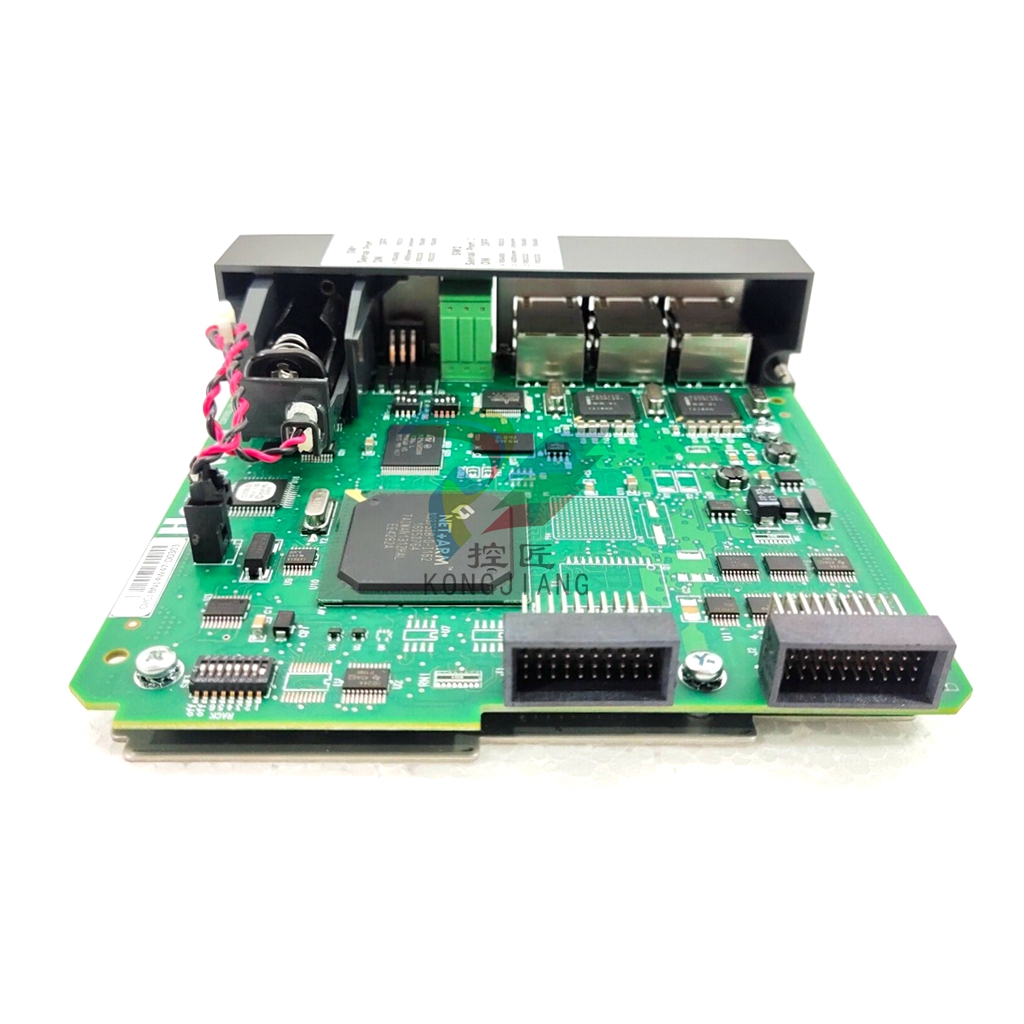

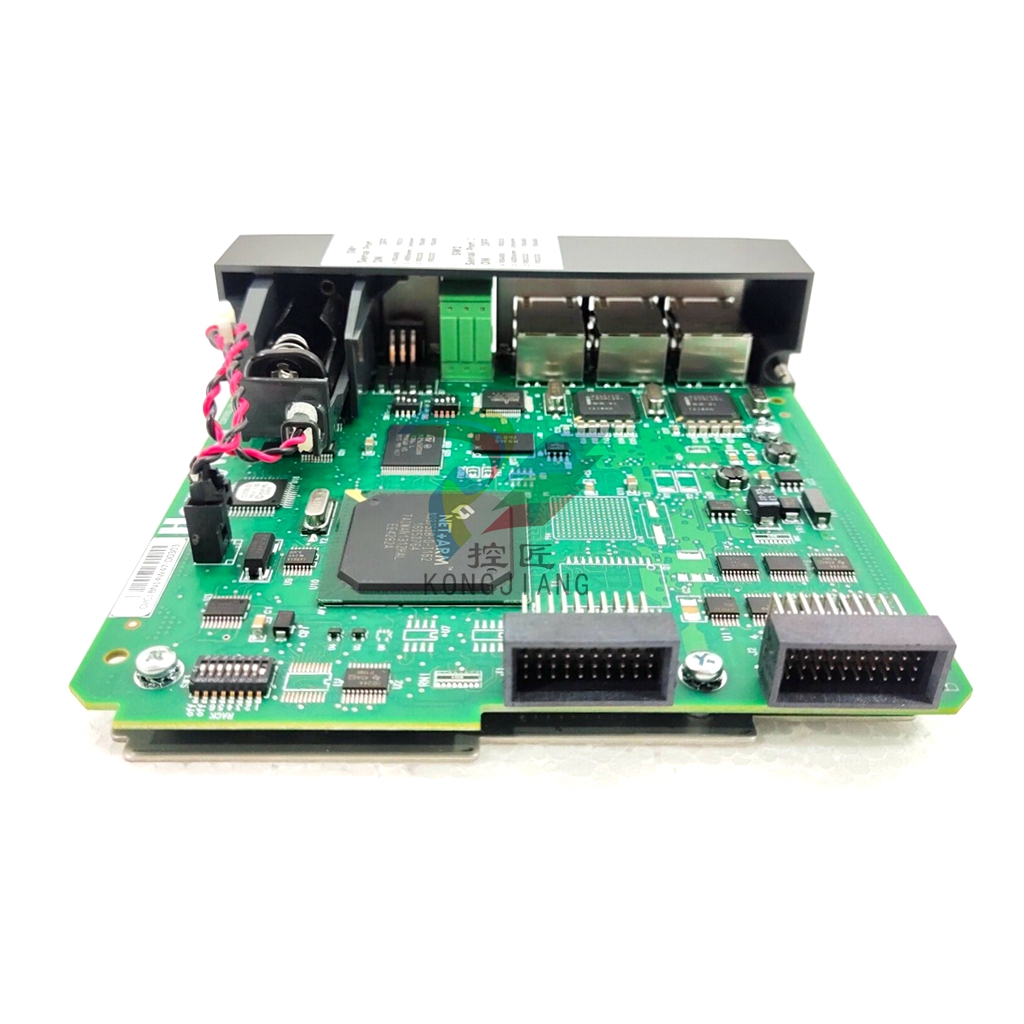

Honeywell 12 I/O Slot Rack 900R12-0200

Item DescriptionController Mode Controller’s mode of operation:

RUN: Controller is running normally.

Note: (For C30S, C50S, C70S and C75S Controllers only)

Blinking RUN text on master slide on lower right hand corner indicates

controller is in invalid mode, which means there are some forced output(s)

present in Safety portion of the controller configuration and user changed the

controller mode to RUN-LOCKED mode from RUN-PRGM mode.

PROG: Controller is in Program mode.

OFLN: Controller is in Offline mode.

FAULT: A fault was found reading the Controller switch.

NO COMM: This is displayed if controller is not responding.

Frequency (Hz) Line frequency. Used for configuring the conversion time of the A/D converter.

Cycle Time (Sec) The analog control cycle time in seconds. This value is determined from the

execution time estimated from the configured control scheme. Cycle Time and

Fast Cycle Time increase (slow down) as the following increase: CPU % Used,

Fast CPU % Used, Dynamic Memory, Config Memory. Also, extensive use of

Free Form Logic blocks (as opposed to equivalent gate logic) can substantially

increase Fast Cycle Time.

CPU Percent used Calculation of percentage of time the CPU is active during the analog cycle time

Peak time (sec) Maximum time used to complete the analog cycle

Control Block

Overruns

Number of times that the processing of the analog control blocks exceeds the

allocated analog cycle time

Fast Logic Cycle Time

(Sec)

Cycle Time and Fast Cycle Time increase (slow down) as the following

increase: CPU % Used, Fast CPU % Used, Dynamic Memory, Config Memory.

Also, extensive use of Free Form Logic blocks (as opposed to equivalent gate

logic) can substantially increase Fast Cycle Time.

Fast Logic CPU Per

Cent Used

Calculation of percentage of time the CPU is active during the processing of

digital control blocks

Fast Logic Peak Time

(Sec)

Maximum time used to complete the digital control cycle

Fast Logic CB

Overruns

Number of times that the processing of the digital control blocks exceeds the

allocated digital cycle time

Controller Setup

The current controller mode is indicated on the bottom right of the display.

Table 4 Controller Setup details

Item Description

Set Controller Time

and Date

Set the controller time and date.

Change mode of the

controller

Run Mode: Select this to resume running the process.

Offline Mode: Select this before performing AI calibration.

Program mode: Select this:

• Before performing AI and AO Calibration.

• To turn off all of the controller outputs while reconfiguring a control strategy.

Cold Start: Refreshes the Flash memory of the controller so that if your battery goes

dead the data in Flash is up to date. Use the Program mode for changes whenever

possible.

Write To Flash Write controller database to Flash memory. Controller must be in the Run, Run Locked,

or Offline Mode. Saves any parameters that you may have changed in the controller to

the controller’s non-volatile Flash memory. The affected parameters include:

Loop tuning parameters (gain, rate, reset, etc.)

Changes to Recipes, Profiles, Schedules, and Sequences.

If the write fails, upload the controller's configuration to the PC (using HC Designer) and

save the uploaded configuration to disk to make sure that you have captured all of the

non-volatile parameter changes.

Summary Displays

About Summary Displays

There are six summary displays to show the I/O blocks present in the Controller and the variables in the

configuration. The six summary displays are:

• Analog Input Summary

• Analog Output Summary

• Analog Variable Summary

• Digital Input Summary

• Digital Output Summary

• Digital Variable Summary

The Analog Input and Output Summary Displays show the following fields.

1. Physical Address of the Block (RMC)

• Rack Number

• Module Number

• Channel Number

2. Tag

3. Description

4. Value

5. Units

6. Error Status

The following additional fields are displayed when an I/O Safety Function block Analog Input Voting is

configured.

7. Channels A,B, and C

8. VFAIL

9. SFAIL

The following additional fields are displayed when an I/O Safety Function Block Analog Output Validated

is configured.

7. VFAIL

8. FBFAIL

The Analog Variable Summary Display shows the following fields:

1. Variable Number

2. Tag

3. Description

4. Value

5. Units

The Digital Input Summary Display shows the following fields:

1. Physical Address of the DI Block (RMC)

• Rack Number

• Module Number

• Channel Number

2. Tag

3. Description

4. State

5. Error Status

The following additional fields are displayed when an I/O Safety Function block Digital Input Voting is

configured.

6. Channels A,B, and C

7. VFAIL

8. SFAIL

The following additional fields are displayed when an I/O Safety Function Block Digital Output Validated

is configured.

6. VFAIL

7. FBFAIL

The Digital Output Summary Display shows the same information as above plus the Type of the module.

The Digital Variable Summary Display shows following fields:

1. Variable Number

2. Tag

3. Description

4. Data