ABB BRC100 Bridge Controller and Processor Bus Adapter

The BRC-100 Harmony Bridge Controller is a high-perfor�mance, high-capacity process controller. It is a rack controller

designed to interface with both Harmony I/O blocks and Har�mony rack I/O in the Symphony Enterprise Management and

Control System. The Harmony bridge controller is fully com�patible with the INFI 90® OPEN system in functionality, com�munication and packaging. The Harmony bridge controller

collects process I/O, performs control algorithms and outputs

control signals to process level devices. It also imports and

exports process data of other controllers and system nodes,

and accepts control commands from operators and computers

connected to the network.

This instruction provides information about how the Harmony

bridge controller works, and how to install, configure, operate

and troubleshoot the module.

The Harmony bridge controller is designed for redundancy.

This can be achieved while remaining connected to the Hnet, or

without, using an optional BRC redundancy kit.

ABB will provide assistance in the operation and repair of its

products. Requests for sales or application services should be

made to your nearest sales or service office. ABB can also pro vide installation, repair and maintenance contract services.

When ordering parts, use nomenclature or part numbers and

part descriptions from equipment manuals. Parts without a

description must be ordered from the nearest sales or service

office. Recommended spare parts lists, including prices are

available though the nearest sales or service office.

ABB has modern training facilities available for training your

personnel. On-site training is also available. Contact your

nearest ABB sales office for specific information and schedul ing.

Additional copies of this instruction, or other instructions, can

be obtained from the nearest ABB sales office at a reasonable

charge.

The BRC-100 Harmony Bridge Controller is a high-perfor mance, high-capacity process controller. It is a rack controller

designed to interface with both Harmony I/O blocks and Har mony rack I/O in the Symphony Enterprise Management and

Control System. The Harmony bridge controller (BRC) is fully

compatible with the INFI 90 OPEN system in functionality,

communication, and packaging.

The Harmony bridge controller is a stand-alone controller that

can handle specific control and information processing appli cations in addition to multiple-loop analog, sequential, and

batch control. It has the power to execute demanding process

control applications that are data intensive, program intensive

or both. The Harmony bridge controller supports multiple con trol languages which include function codes,C, Basic,

Batch 90, and Ladder.

The Symphony system uses a variety of analog, control, and

digital I/O devices to interface with the process. Control input/

output is available from I/O blocks using the Harmony com munication network (Hnet) or from Harmony rack I/O modules

using the I/O expander bus.

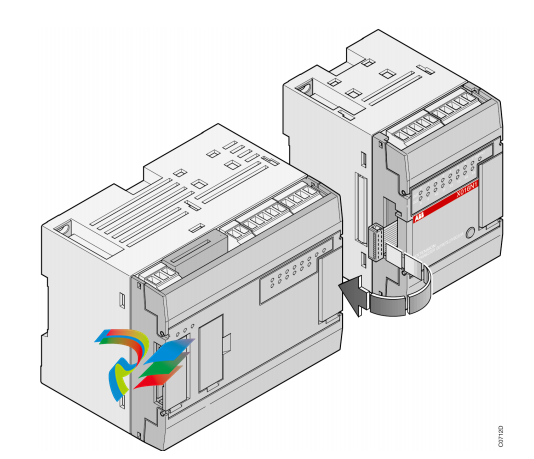

For added reliability, the BRC module has circuitry that sup ports redundancy. A backup BRC module waits in a standby

mode while the primary module executes. If the primary goes

offline for any reason, there is a bumpless transfer of control to

the backup module. A processor bus adapter (PBA) board is

required to support redundant BRC modules and redundant

Hnet buses. When no Hnet and termination unit connection is

needed, a BRC redundancy kit may be used to support redun dant BRC modules.

IISAC01 Analog Control Stations can connect directly to the

BRC module via a PBA board and termination unit. The BRC

module also supports IISAC01 stations that are connected to a

Harmony control I/O block (CIO-100/110) on the Hnet bus or

a Harmony control I/O module (IMCIS12, IMQRS12) on the I/

O expander bus. The BRC module supports up to 128 SAC sta

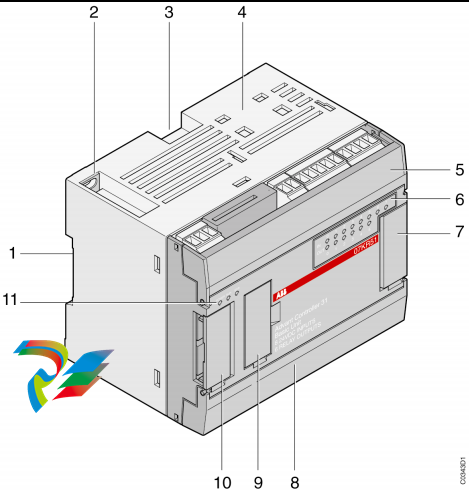

Hardware Description

The Harmony bridge controller consists of a circuit board and

a faceplate.

Faceplate

The BRC faceplate measures 35.56-millimeters wide by

177.80-millimeters high (1.4-inches wide by 7.0-inches high).

Two latching screws, one at the top, the other at the bottom,

lock the module assembly in a module mounting unit (MMU). A

transparent window on the faceplate enables viewing the 16

CPU LEDs and the status LED. These LEDs display operating

information. A small hole directly below the window provides

access to the combination stop/reset pushbutton. Besides

locking the module in place, the faceplate also protects the cir�cuit components and promotes proper air flow within the

enclosure.

Circuit Board

The circuit board features state-of-the-art surface mount tech�nology. On the board are nonvolatile random access memory

(NVRAM), static random access memory (SRAM), flash memory

(ROM), a microprocessor running at 32 megahertz, direct

memory access (DMA) circuits, ABB Process Automation cus�tom bus circuits, and various support circuitry. The board

attaches to the faceplate with two screws. The module assem�bly occupies one slot in a module mounting unit.

A processor bus adapter board is required for connection to the

Harmony I/O subsystem via Hnet. It also connects to a termi�nation unit for two auxiliary serial I/O ports and IISAC01 sta�tions. Redundant BRC modules and Hnet buses connect

through redundant PBA boards.

Hardware Application

Because of the superior performance of the BRC module, appli�cations that formerly required an external mainframe or mini�computer can now be handled in the Harmony control unit.

The large memory space and on-board communication ports of

the BRC module enable it to meet the sophisticated control