K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

Troubleshooting

IntroductionThis section provides troubleshooting information necessary to

isolate HCU interface errors. It is not meant to be all inclusive.

If a problem exists that cannot be corrected using the informa tion provided in this instruction, contact a local ABB service

office for assistance.

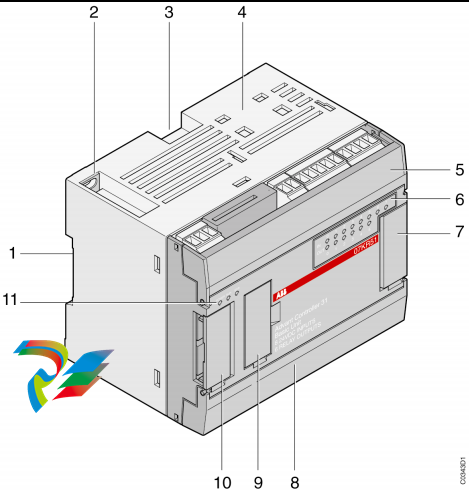

ABB INNPM12 Counter module

Troubleshooting

Introduction

This section provides troubleshooting information necessary to

isolate HCU interface errors. It is not meant to be all inclusive.

If a problem exists that cannot be corrected using the informa tion provided in this instruction, contact a local ABB service

office for assistance.

Troubleshooting Procedures

Troubleshooting the HCU interface is limited to deciphering

module LED error codes and viewing the contents of the error

counters and the module status report from any human sys tem interface (HSI). Refer to the instruction for the specific HSI

workstation being used for information on module status

reports.

Error Codes

All Cnet communication modules have faceplate LEDs that

serve as error code displays. The INNIS01 module has event

and error counters that are selectable.

INNIS01

The INNIS01 module error counters total errors in the same

manner as the event counters total events. Table PR5-6 lists

the types of error counters. The module halts operation if a

fatal error condition occurs. Group A LEDs on the module face plate display error codes. Group B LEDs are off when group A

LEDs are displaying any error code. Refer to Table 5-1 for a list

of error codes and associated corrective actions.

INNPM12

If errors occur while the INNPM12 module is operating, the sta tus LED turns on red and the CPU LEDs on the module face plate display error codes. Table 5-2 lists the INNPM12 module

Diagnostics

The firmware of the INNPM12 and INNIS01 modules contain

various diagnostic routines used to verify proper operation of

components and circuitry. Some are run automatically during

startup and normal operation (online), and others can be

invoked manually (offline). If any of the online checks detect a

hardware problem, the module will provide error status code

indications (if possible) and will halt. Refer to Tables 5-1 and

5-2 to decipher the status codes.

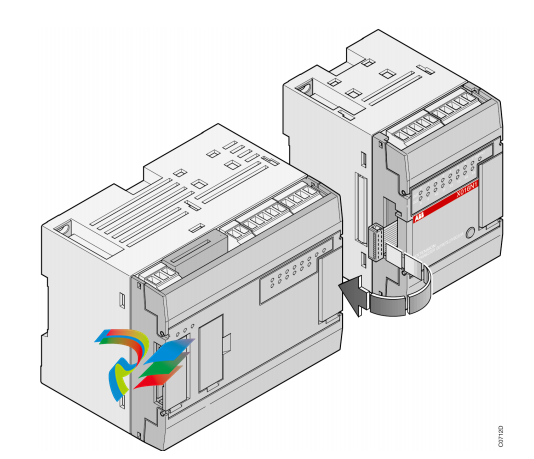

Offline tests can be run to verify operation of suspect INNPM12

modules or to check module integrity before putting it into

operation. Offline diagnostics should only be run during

installation or when a system is down. Refer to procedure sec tion PR14 for the steps to run offline diagnostics. Putting the

INNPM12 module into diagnostic mode allows it to perform a

variety of diagnostic tests but suspends normal operation.

INNPM12 Status Summary

The INNPM12 presents two different status summaries

depending on its mode of operation (i.e., Cnet or Plant Loop

mode) set with switch SW3 (refer to Table PR6-1). In Cnet

mode, INNPM12 has a 16-byte module status record. In Plant

Loop mode, INNPM12 has a five-byte module status record. In

either case, the status report provides summary flags for error

conditions, module type, and firmware revision level.

The status report can be viewed from a human system inter face. To interpret the status bytes:

1. Convert each hexadecimal byte to its binary equivalent.

For example (Cnet mode):

Refer to Tables 5-3 and 5-4 for an explanation of each byte and

data bit.

Byte 1 0x75 = 01110101

Bit 7 0 = no errors.

Bit 6/5 11 = execute mode.

Bit 4-0 10101 = enhanced node type; reference

byte 6 (ETYPE) for actual type.

Cnet Mode

Table 5-3 lists the fields that make up the INNPM12 module

status report when in Cnet mode. Table 5-4 describes each

field within the module status record.

Table 5-3. INNPM12 Status Byte Description (Cnet Mode)

ByteBit76543210

1 ES MODE TYPE

2 Reserved

3 CSP MOV BKCFG BKSTS PSI

4 NSF LR1 LR2 LT1 LT2 RI1 RI2 RCF

5 Reserved

6 ETYPE

7 CWA CWB

8 Reserved

9 NDT1 NDT2 NCD1 NCD2

10 - 13 Reserved

14 Module nomenclature

15 Revision letter (ASCII)

16 Revision number (ASCII)

Table 5-4. INNPM12 Status Bit Descriptions (Cnet Mode)

Byte Field Field Size or Value Description

1 ES 80 Error summary: 0 = good, 1 = errors

MODE 60 Module mode: 10 = error, 11 = execute

TYPE 1F Module type: 0x15 = enhanced status (ETYPE)

2 — 00 Reserved

3 CSP 80 Communication status problem: 0 = no, 1 = yes

MOV 40 Memory overflow: 0 = good, 1 = bad

BKCFG 10 Redundant configuration: 0 = no, 1 = yes

BKSTS 08 Backup failed: 0 = no, 1 = yes

PSI 00 Primary/backup indicator: 0 = primary, 1 = backup

4 NSF 80 Node environment status flag: 0 = good, 1 = bad

LR1 40 Cnet 1 receive error: 0 = no, 1 = yes

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923