K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

Event and alarm lists are also available and expor table as CSV format for documentation. The data

of the lists are stored on the flash which makes it

power failure proof.

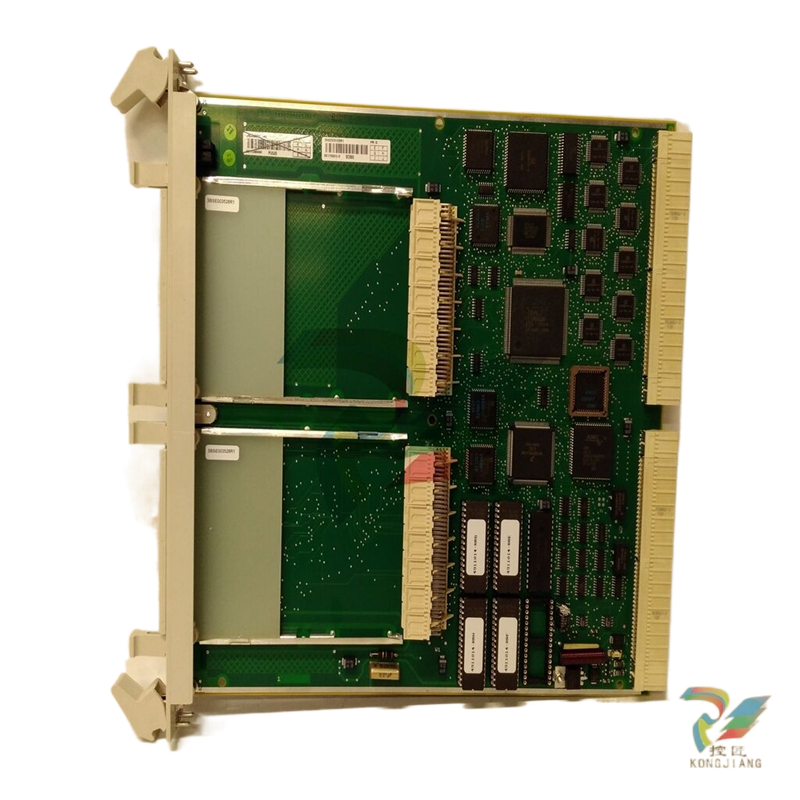

ABB 1TGE120011R1001 UN 6000 high voltage inverter accessories

For basic local monitoring and basic control an

Human Machine Interface was integrated into the

RTU560. The HMI-functionality itself is an integrated part of the RTU560 functionality;no additional

SCADA product is needed.Single line pictures with

active monitoring and control elements are stored

on the CMU of the RTU560.

Event and alarm lists are also available and exportable as CSV format for documentation. The data

of the lists are stored on the flash which makes it

power failure proof.

The only software requirement for visualization

on a PC is the Java Virtual Machine Freeware. The

single line diagram allows an instant overview of

the substation. The picture editor has a symbol

library with predefined dynamic symbols. The picture editor contains different language and character sets. The component editor enables the user to

create customer specific symbols in case they are

not available in the standard libraries.

The editor allows easy linking of dynamic symbols

to the RTU560 runtime data to prevent engineering faults.Access authority for different users or

groups together with command authority is essential for secure operation. Therefore this feature is

also an integrated component of the RTU560.

RTU560 diagnosis system is based on the web

server technology. Therefore no special tools are

required to analyse the RTU560.The diagnosis

could be carried out either locally or remote via

LAN/WAN.

All RTU560 modules are maintenance free.Due to

the small numbers of different modules,spare part

stock is kept to a minimum.Since the application

data is stored on Compact Flash CardsTM it is pos sible to exchange modules without new configu ration download.

The functional operation of the RTU560 is guaran teed by a comprehensive monitoring concept. The

hardware and software is continuously monitored

from the I/O boards throughout the entire RTU.

The hardware and software monitoring is carried

out by active checks at several levels.

The diagnosis concept of the RTU560 is conse quently adapted to the possibilities of modern

communication.Once access to the RTU560 by

Intranet has been established,all of the RTU560's

relevant information can be read out from any

location by a laptop.

This system can be used for a checkup of the con figuration or signal values and statuses.

It allows service personnel to analyse and possibly

solve a RTU problem from their office rather than

making an unnecessary visit to the station.

On the other hand,when travelling to the site is

inevitable,the required spare parts can be determi ned beforehand.

Remote access via Intranet is combined with

authority privileges for the user.It is possible to:

• Monitor the RTU-produced internal

error messages

• Monitor and check the RTU560 configuration

and the status of all connected process signals

• Check the current version of the configuration file

• Down- or upload the RTU560 configuration file

• Check and download revised software files

for the RTU560 CMU boards

• Upload the archive files

Access to each communication board is granted

individually. The presentation of process informa tion about statuses and values is presented in such

a way that the service personnel are able to work

with the same designations (object identification

keys) as the operator in the control station.

The following data can be stored with time stamp:

• Process events of the RTU560 and connected

subsystems (subordinate RTUs,IEDs,protection

relays)

• Virtual data points (e.g.calculated values of PLC

function)

• User login

• Commands

• System events and messages

• Analogue measured values

• Integrated totals (counter values)

• File archive (Load profiles of metering devices,

Disturbance records of protection relays)

The archive data are accessible via:

• Web server,front MMI (cable)

• Web server,TCP/IP channel (remote,WAN/LAN)

• CSV export (text file),Import in MS-ExcelTM

• Local print function to serial printer

• Data of the File archives are also accessible via

file transfer

The RTU560 is able to handle and file archive data

which are protected against voltage loss (Compact

Flash CardTM).

The File archive can handle the following file

types:

• Disturbance recorder files of connected pro tection relays/bay controller via IEC60870-5-103

• Disturbance recorder files of some connected

protection relays/bay controller via SPABUS

• Load profiles of connected metering devices

(e.g.IEC62056-21)

• Disturbance recorder of connected subordinated

RTUs with IEDs are supported

• The upload to Flash memory is running auto matically

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923