K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

Continuous productivity improvements and increased profitability are the driving

force behind today’s automation system. Furthermore, systems must support users

with the power to react quickly to ever rising demands from the markets they serve

ABB CBI20-P MR Series (Melody Rack)

Continuous productivity improvements and increased profitability are the driving

force behind today’s automation system. Furthermore, systems must support users

with the power to react quickly to ever rising demands from the markets they serv

Features and benefits

Flexible, cost-effective assembly

Decentralized, DIN rail-mounted controller

assembly can be combined with local or

remote I/Os.

Comprehensive I/O system

A wide range of local and remote I/O is available

with integrated intrinsic safety design and

transmitter power supply options. Features

such as sequence of events (SOE) time stamping

(1 ms resolution), monitoring, filtering, as well

as HART, PROFIBUS, Modbus RTU and TCP

communication are supported with a wide range

of I/Os such as Melody Rack local I/O, ABB’s S800

and S900, and other remote PROFIBUS I/Os.

Distributed capability

ABB’s S800 and S900 remote I/O and Melody

Rack local I/O are connected via high-speed serial

communication buses. Local I/O offers a high

packing density to reduce mounting space to

a minimum, whereas remote I/O fully supports

distributed system configurations.

Efficient field device integration

Standardized field device tool/device type

manager (FDT/DTM) interfaces enable plug and-play integration of field devices.

Easy to configure

Module configuration and service is executed

using S+ Engineering for Melody and its unrivaled

library of fully tested and field-proven powerful

function blocks.

Inherent redundancy design

System-integrated redundancy options for power

supply, hardware and communication networks

provide the highest level of availability.

High performance modular network

Symphony Plus MR Series based control systems

uses a redundant, high-speed serial communi cation network with inherent capability for

remote communication. The network is

easy to expand without requiring routing

configuration.

Overview

The MR Series includes a series of compact DIN

rail mounted controllers, a wide range of I/O

modules and modern, standardized fieldbus

interfaces. These modules offer all the

functions required for data acquisition and signal

conditioning, as well as powerful open loop

and closed loop control, sequence control and

monitoring. All process management

tasks are executed on the basis of integrated

complex control strategies. Without the need

for configuration, The MR Series inherent

redundancy design – including integrated

redundancy concepts for power supply,

communication and I/O – provides the highest

level of availability.

Key features include:

• A wide range of I/O interfaces with optionally

integrated intrinsic safety (Ex i) design and

transmitter power supply. Features such as

time stamping with a 1 ms resolution,

monitoring, filtering and HART communication

are implemented directly in the I/O modules

• PROFIBUS interfaces provide connections to

ABB’s S800 and S900 remote I/O stations in

Ex and non-Ex versions, as well as other

PROFIBUS devices

• IEC 61850 interface to intelligent electronic

devices (IEDs) for the integration of electrical

subsystems

• Modbus RTU and TCP interfaces provide

connections to 3rd party devices

02 Functional overview of MR Series capabilities

• The MR Series control network uses a

redundant, high-speed serial communication

network with inherent capability for remote

communication. The network is easy to handle,

without requiring routing configuration

• Flexible mounting alternatives such as cabinet,

DIN rail or 19” rack mounting. All three can be

combined in one project. This allows optimal

adaptation to all plant structures and supports

flexible upgrades of existing installations

• An unrivaled high packing density in the

system cabinets saves installation space

• Controller time synchronization based on

a time precision of 0.5 msec

• Sequence of events (SOE) time stamping

with a resolution of 1 ms is implemented

in the controller and local I/O module level

The control subsystem includes flexible

communication options to I/O and intelligent

field devices via system buses. HART as well as

PROFIBUS information, including configuration

and diagnostic information, is communicated

via the control network. This information is

available to system controllers and system

level applications such as asset optimization

and device management. The comprehensive

bus concept of the system controller allows

for the easy integration of HART, PROFIBUS,

Modbus RTU and TCP field devices as well as

of PROFIBUS and IEC 61850 electrical assets.

The MR Series functional capabilities are

summarized in figure 2.

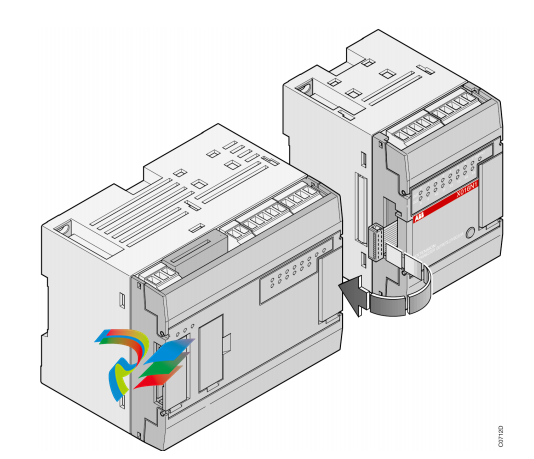

Scalable control stations

MR Series control stations are conveniently

set up according to project needs and are made

up of modular controllers and I/Os. Depending on

the scope of the automation task, the controller

is extended with I/O modules or communication

interfaces.

The controllers are connected via the control

network to ensure reliable, high speed and

system wide real-time signal exchange with

other control stations, with S+ Operations,

with system level applications and with

S+ Engineering for Melody.

Each node on the control network operates

autonomously. Acting as its own communication

manager, the system requires no traffic directors.

The controller’s associated I/O modules are

connected using the high-speed redundant serial

field network or PROFIBUS DP (DPV1 as well as

DPV2).—

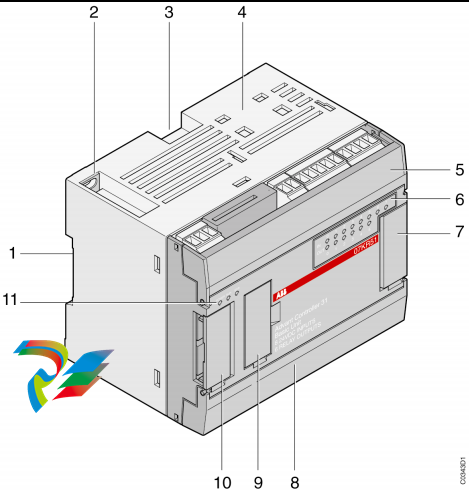

MR Series controllers

Melody controllers are designed for maximum

computing power and modular scalability.

Each controller can handle up to 2,000 analog

and/or digital I/O points from the local I/O, and

additionally 6,000 analog and/or digital I/O

points connected via PROFIBUS DP. In addition

to the standard tasks such as signal processing,

loop and logic control, the MR Series controller

also performs complex computations such as

sequential, batch and advanced controls.

Diagnostic routines periodically check the

hardware and firmware integrity. Any abnormal

conditions are automatically routed to the HMI

or other alarm or message collecting software.

The redundant design provides an automatic

one- to-one backup, thus ensuring high system

availability. If the primary controller is faulty, the

hot standby controller, executing the same

control strategy and process data, immediately

takes over control.

MR Series controller key features include:

• Large variety of powerful functions available

in tested libraries

• Easy configuration, service and commissioning

with S+ Engineering

• Inherent redundancy without configuration/

wiring costs

• Real-time multitasking operating system

• Up to 16 different cycle times

• Comprehensive monitoring and diagnostic

functions

• Interface for radio clock connection

• Bumpless downloadable firmware and

application programs (no EPROMs)

• Cyber security proven

• PM 877 without battery

The range of available function blocks extends

from simple control and individual drive functions

to complex recipes based on S88 and NAMUR

using sequential function charts based on IEC

61131-3.

Function blocks may also be used to set up

customer-specific libraries in S+ Engineering

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923