K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Current position:

Brand

Description

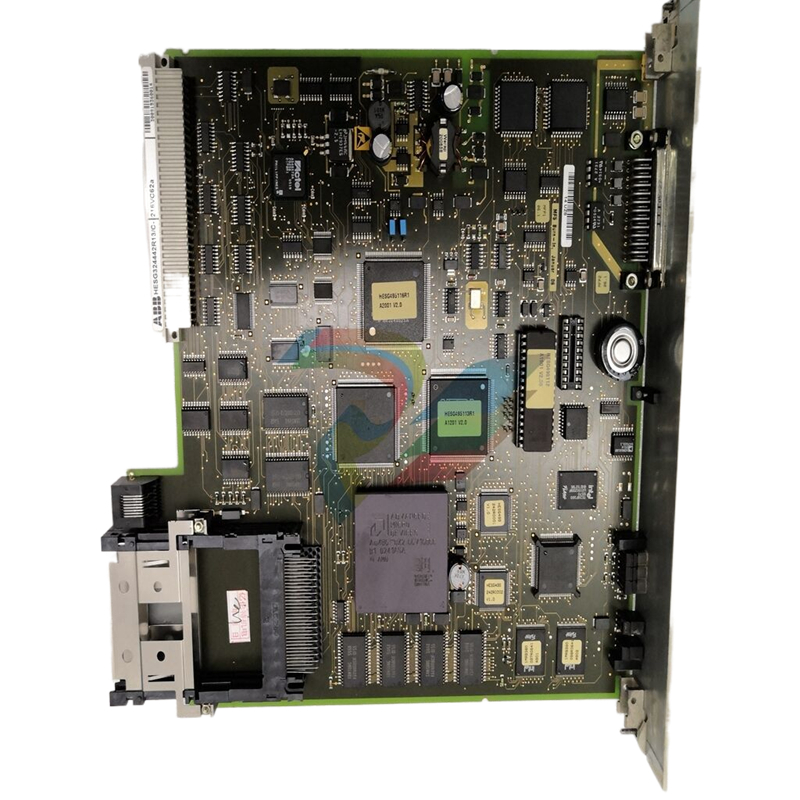

Introducing the ABB DSQC612: A High-Performance Solution for Modern Automation Needs

ABB DSQC612 - Ethernet Board: Industrial Control Module, High Performance, Seamless Integration

ABB DSQC612 - Ethernet Board: Industrial Control Module, High Performance, Seamless Integration

Introducing the ABB DSQC612: A High-Performance Solution for Modern Automation Needs

In the fast-evolving landscape of industrial automation, the ABB DSQC612 stands out as a reliable and efficient controller designed to meet the rigorous demands of modern manufacturing processes. As part of ABB’s extensive portfolio of automation products, the DSQC612 combines advanced technology with user-friendly features, making it an essential component for enhancing operational efficiency and productivity.

Key Technical Features

The ABB DSQC612 is engineered with cutting-edge specifications that ensure optimal performance in various applications. Some of its key technical features include:

1. **Robust Processing Power**: The DSQC612 is equipped with a high-speed processor that enables rapid data processing and real-time communication, ensuring uninterrupted operations in demanding environments.

2. **Versatile I/O Capabilities**: With multiple input and output configurations, the DSQC612 supports a wide range of sensors and actuators, allowing for flexible integration into different automation systems.

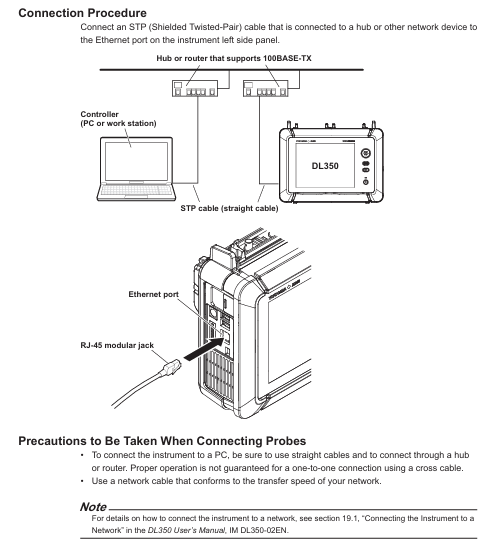

3. **Enhanced Communication Protocols**: The device supports various communication protocols, including Ethernet and fieldbus options, facilitating seamless integration with other ABB automation products and third-party devices.

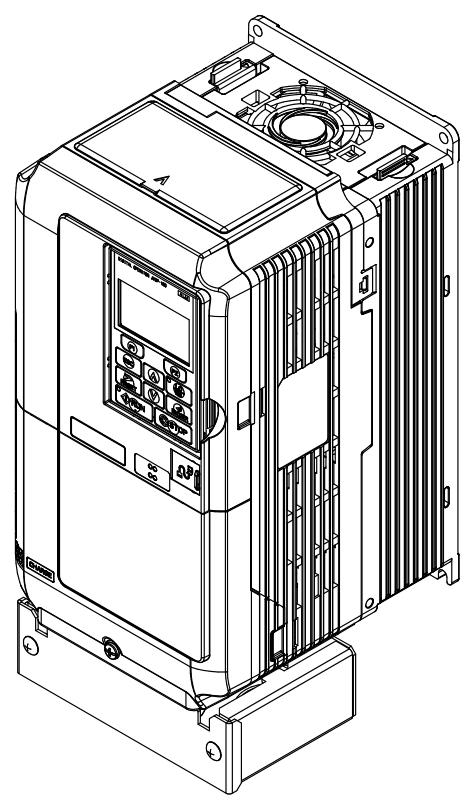

4. **Compact Design**: Its compact form factor allows for easy installation in space-constrained environments, making it suitable for both new installations and retrofitting into existing systems.

5. **High Reliability and Durability**: Built to withstand harsh industrial conditions, the DSQC612 features robust housing and protection against dust and moisture, ensuring long-lasting performance even in challenging settings.

6. **User-Friendly Interface**: The intuitive interface simplifies setup and configuration, reducing downtime and operational costs, while also enhancing user experience.

Usage Scenarios

The ABB DSQC612 is versatile and can be deployed in a variety of industrial automation scenarios. Here are a few examples:

1. **Manufacturing Automation**: In production lines, the DSQC612 can control robotic arms, conveyor systems, and assembly stations, facilitating efficient material handling and processing.

2. **Process Control**: The controller is ideal for managing complex processes in industries such as chemicals, pharmaceuticals, and food and beverage, where precise control and monitoring of variables are crucial.

3. **Machine Automation**: The DSQC612 can be utilized to automate machinery in sectors like automotive and electronics, improving throughput and consistency while reducing manual intervention.

4. **Energy Management**: In energy-intensive applications, the DSQC612 can help optimize energy consumption and improve overall system efficiency, contributing to sustainability goals.

5. **Data Acquisition and Monitoring**: The device can collect and analyze data from various sensors, providing insights for predictive maintenance and operational improvements.

Comparison with Other Models

When comparing the ABB DSQC612 to other models within the ABB automation product lineup, several distinctions become apparent. For instance:

- **ABB DSQC352B**: While both controllers are designed for industrial applications, the DSQC612 offers higher processing speeds and more versatile I/O options compared to the DSQC352B, making it more suitable for complex automation tasks.

- **ABB TU841**: The TU841 is primarily focused on I/O functions, whereas the DSQC612 serves as a comprehensive controller with advanced processing capabilities, making it a more integrated solution for automation.

- **ABB PM864AK01**: The PM864AK01 is designed for specific control tasks, while the DSQC612 provides broader applications across various industries, giving it an edge in versatility and adaptability.

- **ABB ACS880-01-246A-3**: Although the ACS880 series is focused on drives and motor control, the DSQC612's capabilities extend beyond that, allowing for a more holistic approach to automation.

By evaluating these comparisons, it becomes clear that the ABB DSQC612 is a robust choice for companies looking to streamline their operations and enhance productivity.

Reference to Related Models

As part of the ABB ecosystem, the DSQC612 works seamlessly with a range of related models, enhancing its functionality and integration potential. Some notable models include:

1. **ABB UNS1860B-P**: A versatile controller for motion control applications.

2. **ABB IRB 2600**: A compact robot designed for manufacturing tasks.

3. **ABB TU852 S800 I/O**: A flexible I/O module for expanding input/output capabilities.

4. **ABB 07DC91**: A digital output module for controlling various devices.

5. **ABB ACS-CP-C**: A compact drive controller that complements the DSQC612 in motor control applications.

6. **ABB GINT5611C**: A general-purpose industrial network interface for communication.

7. **ABB SDCS-PIN-48-SD**: A modular controller designed for process control.

8. **ABB TB820-1**: A terminal block for connecting various devices within the automation system.

9. **ABB 3HAC16035-1**: A versatile controller suitable for a range of applications.

10. **ABB PM511V16**: A digital input/output module designed for communication with the DSQC612.

Conclusion

In conclusion, the ABB DSQC612 is a powerful and versatile controller that caters to the diverse needs of modern industrial automation. With its superior processing capabilities, robust design, and seamless integration with other ABB automation products, it represents an ideal solution for enhancing operational efficiency, productivity, and flexibility. Whether in manufacturing, process control, machine automation, or energy management, the DSQC612 is poised to meet the challenges of today’s dynamic industrial landscape. Embrace the future of automation with the ABB DSQC612 and unlock new levels of performance and efficiency in your operations.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information