K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Manufacturers

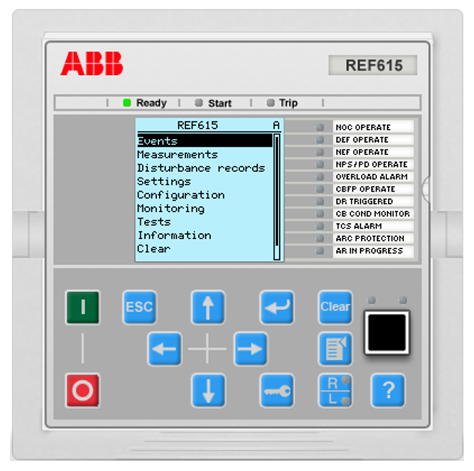

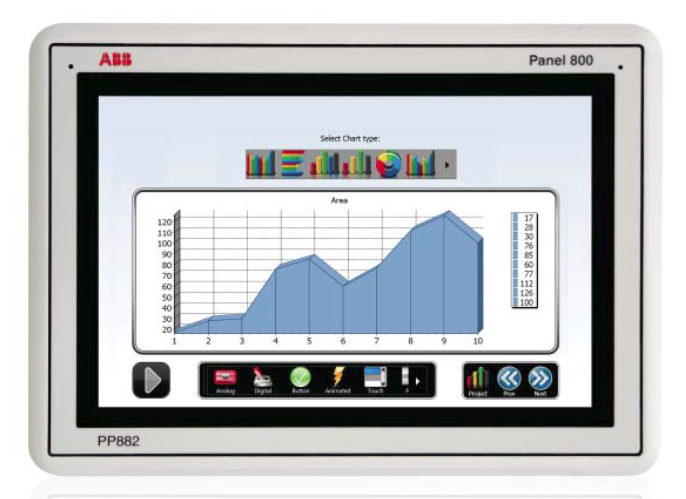

ABB

Model(s)

ABB Advant Controller 31, ABB Advant OCS

Additional Information

07CR41 Advant Controller Basic Unit - 24VDC 8 24VDC Inputs 6 Relay Outputs

Estimated Shipping Size

Dimensions: 4.0" x 4.0" x 5.0"

(10.2 cm x 10.2 cm x 12.7 cm)

Weight: 1 lbs 13.0 oz (0.8kg )

Tariff Code: 8538907080

Country of Origin: Germany

Ships from Webster NY, USA

ABB 1SBP260020R1001 07CR41 Advant Controller Basic Unit - 24VDC

Basic Overview

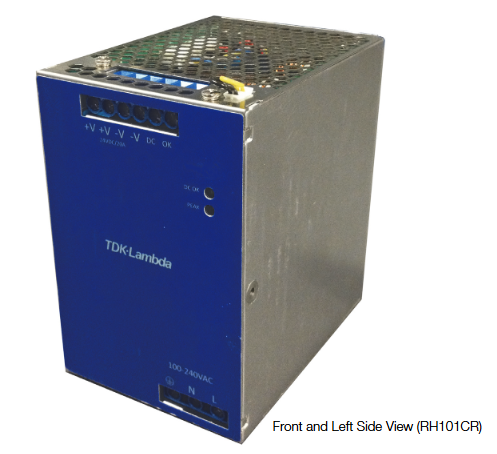

Product Positioning:ABB 1SBP260020R1001 07CR41 Advant Controller Basic Unit - 24VDC is a basic controller unit that operates on 24VDC. It plays a central role in ABB's Advant Controller range and is a key component in building automation control systems.

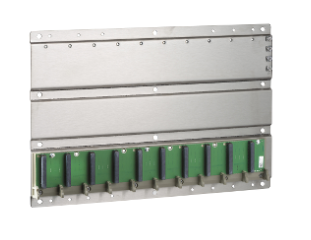

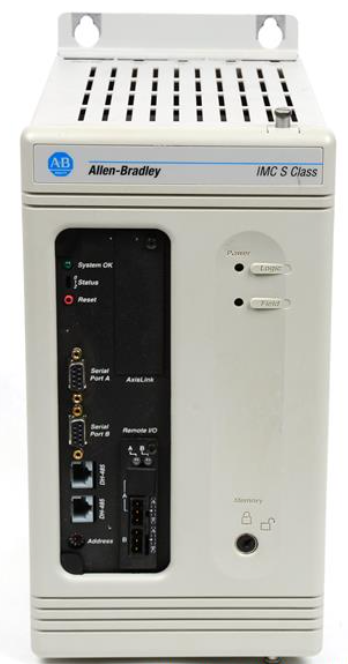

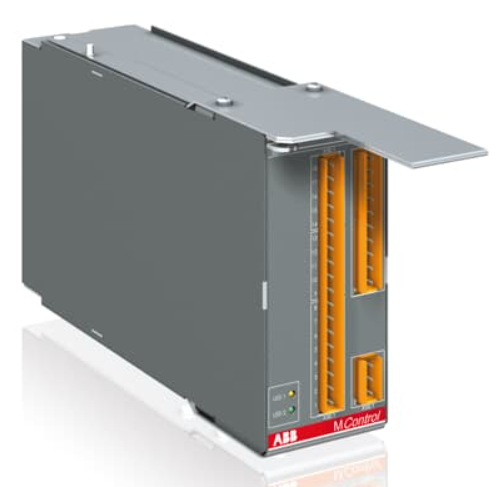

Physical construction: The basic unit is usually of a compact and robust design. The casing is generally metal, which not only provides good electromagnetic shielding for the internal circuitry, but also enhances the mechanical strength of the unit, making it resistant to vibration, shock and a degree of physical damage in industrial environments. The external dimensions are designed for easy installation on standard control cabinet rails, and the layout within the control cabinet is also more flexible.

Functional Characteristics

Processing power

Highly efficient processor: The built-in processor has excellent computing power and is able to quickly process complex control logic. Both simple on/off control and analogue regulation involving complex algorithms, such as PID (Proportional Integral Derivative) control, can be carried out efficiently. For example, in a temperature control system, it can quickly calculate the appropriate control signal through the PID algorithm based on the signal from the temperature sensor, and output it to the heating or cooling equipment to achieve precise temperature control.

Multi-tasking mechanism: It supports multi-tasks running at the same time, which means it can handle several different types of control tasks at the same time. For example, in an industrial production scenario, it can control the rotational speed of a motor while monitoring the data of a pressure sensor, and it can also handle the task of communicating with the host computer at the same time, and it can reasonably allocate system resources to ensure that each task can be executed stably and efficiently.

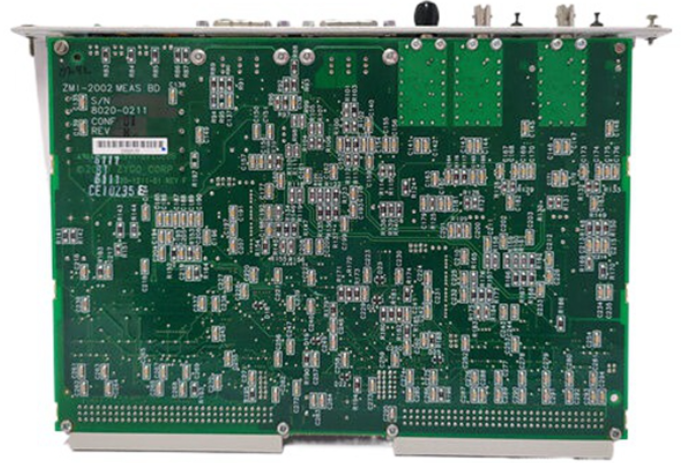

Input/Output Function

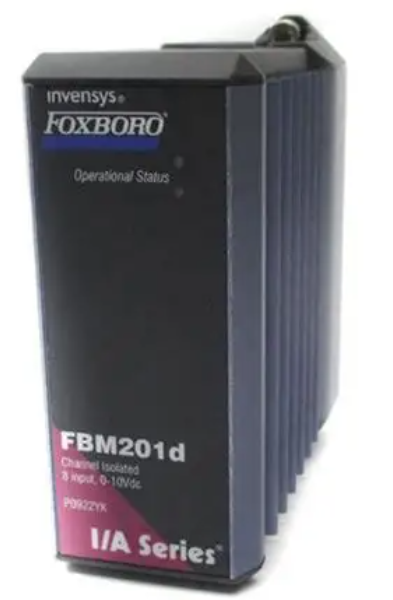

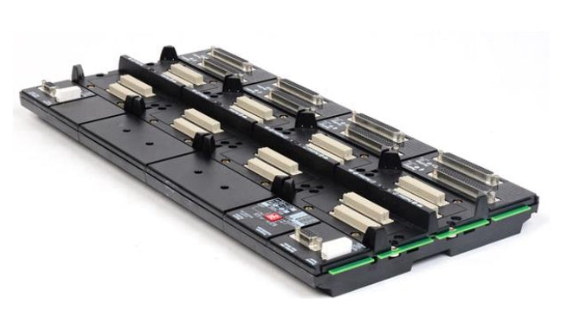

Rich I/O interface types: Equipped with various types of input and output interfaces, including digital input (DI), digital output (DO), analogue input (AI) and analogue output (AO). Digital inputs can receive digital signals from devices such as pushbuttons, limit switches, proximity switches, etc. These signals are typically used to indicate the state of a device (e.g. start/stop, on/off, etc.). Digital outputs can drive relays, indicators, solenoid valves, etc. to control external devices. Analogue inputs can process analogue signals from temperature sensors, pressure sensors, flow sensors, etc. Common signal ranges such as 0 - 10V DC, 4 - 20mA are used to collect various physical quantities in industrial processes. The analogue outputs can output analogue signals to control devices that need to be continuously adjusted, such as frequency converters to control the speed of motors, regulating valves to control the flow rate and so on.

Flexible I/O Expansion: I/O expansion interface is provided, which allows users to flexibly expand the number of input and output points according to the actual application requirements. For example, when more devices need to be controlled or more sensor data need to be collected, the control range and data collection capability of the system can be easily increased by adding appropriate I/O expansion modules to meet the requirements of complex industrial automation systems.

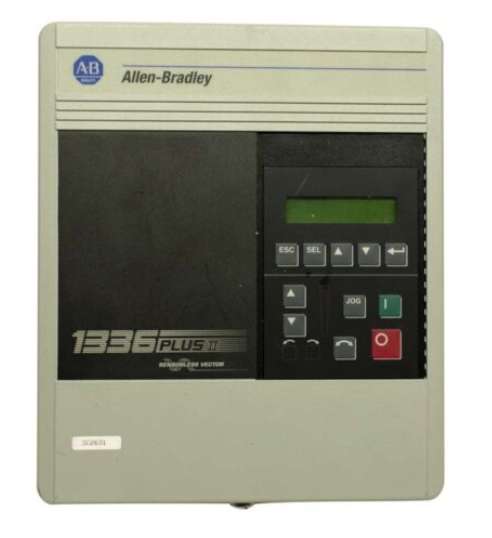

Communication Functions

Various communication interfaces: A variety of communication interfaces are available, such as Ethernet interface (RJ45) and serial interface (RS-232, RS-485). The Ethernet interface supports high-speed data transmission and is suitable for remote monitoring, large data volume communication with the host computer system, and access to the factory's local area network for centralised data management and remote control. Serial interface can be used to connect some specific field devices, or used in close communication scenarios, and in some industrial environments with strong electromagnetic interference, serial communication has better anti-interference ability.

Wide range of protocol support: It supports a variety of industrial communication protocols, such as Modbus, Profibus, TCP/IP and so on. This makes it possible to communicate and exchange data with equipment produced by different manufacturers, which is convenient for users to integrate sensors, actuators and other automation equipment of various brands when building automation systems. For example, in an automation system with both ABB and Siemens devices, seamless data communication and device co-operation can be achieved through these common communication protocols.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|