K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

These Operating Instructions apply to the digital generator

protection REG 216, REG 216 Compact and to the digital control

unit REC 216. In these instructions, the designation RE.216 is

used to refer to both types.

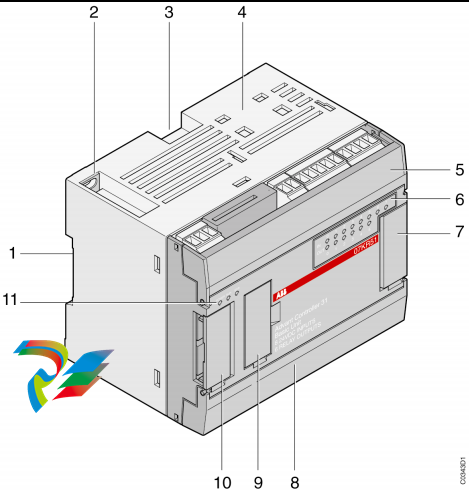

ABB REC216 Numerical Generator Protection

INTRODUCTION

These Operating Instructions apply to the digital generator

protection REG 216, REG 216 Compact and to the digital control

unit REC 216. In these instructions, the designation RE.216 is

used to refer to both types.

Application of the protection system

A number of different protection functions are provided in the

software permanently stored within the RE.216 system.The

functions required to protect a specific plant can be individually

selected, activated and set. A particular protection function may

be used several times in different protection schemes. How the

signals are to be processed by the protection for the plant in

question such as the assignment of tripping, signalling and logic

signals to the various inputs and outputs is also determined by

appropriately configuring the software.

The system hardware is modular in structure. The number of

electronic devices and I/O units actually installed, for example, to

increase the number of protection functions or for purposes of

redundancy, can vary according to the requirements of the par-

ticular plant.

Because of its modular design and the possibility of selecting

protection and other functions by configuring the software, the

generator protection REG 216 can be adapted for the protection

of small, medium and large generators as well as large motors,

power transformers and feeders, while the control unit REC 216

can perform data acquisition and control and supervision

functions in medium and high-voltage substations.

Other relevant documents

A general description of the system and the electronic devices

and I/O units installed and the corresponding technical data are

to be found in data sheet 1MRB520004-Ben "Type REG 216 and

Type REG 216 Compact Generator Protection".

Each RE. 216 protection system is engineered to fulfil the par-

ticular requirements of the plant concerned. A specific set of

diagrams is provided for each installation, which defines the

system with respect to the electronic devices and 1/O units in-

stalled, their locations and the internal wiring.

The set of plant diagrams includes:

single-line diagram of the protection: complete representation

of the plant showing the c.t. and v.t. connections to the

protection.

standard cable connections: block diagram showing the

protection equipment cabling (electronic equipment racks to

I/O units).

protection cubicle layout: installation and locations of the

electronic equipment and I/O units.

electronic rack layout: equipment locations within a rack.

measurement circuits (three-phase plant diagram): connec-

tion of the c.t's and v.t's to the protection.

auxiliary supply: external connection and interal distribution

of the auxiliary d.c. voltage supply.

I/O signals: external connection and internal wiring of the

tripping and signalling outputs and the exteral input signals.

General instructions

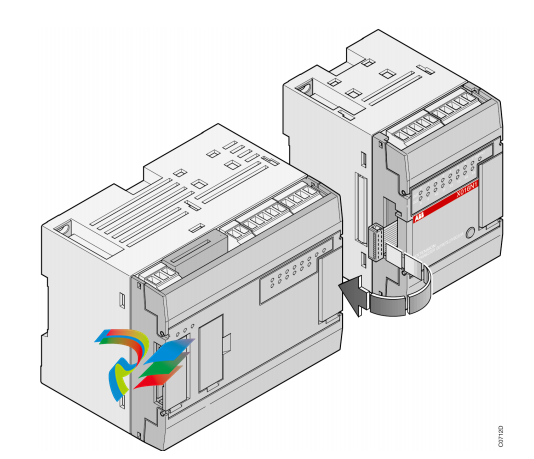

The electronic units may only be inserted into or removed from

the equipment rack when the auxiliary supply is switched off!

The auxiliary supply is switched off by means of a switch on the

auxiliary d.c. supply units 216NG61,resp. 216NG62 or 216NG63.

The following must be noted in this respect:

Every electronic equipment rack is equipped with its own

auxiliary power supply unit.

Either one or a maximum of two redundant216NG6.auxiliary

d.c. supply units can be installed in an equipment rack.

Where two redundant auxiliary d.c. supply units are fitted,

both units must be switched off.

(See also Section 2.2.)

Any work carried out on the protection such as interal adjust-

ments, inserting soldered jumpers, wiring,connections etc., may

only be performed by suitably qualifed personnel.

In addition to these instructions, all applicable local regulations

governing work and safety must be strictly observed when in-

stalling, wiring and commissioning the protection.

Modifications and repairs to the electronic units or software

changes may not be performed by the user. No liability will be

accepted and any warranty becomes invalid in the case of im-

proper interference or tampering with the protection equipment.

Defective units must be returned to ABB for repair (see alsoSection 7.).

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923