K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

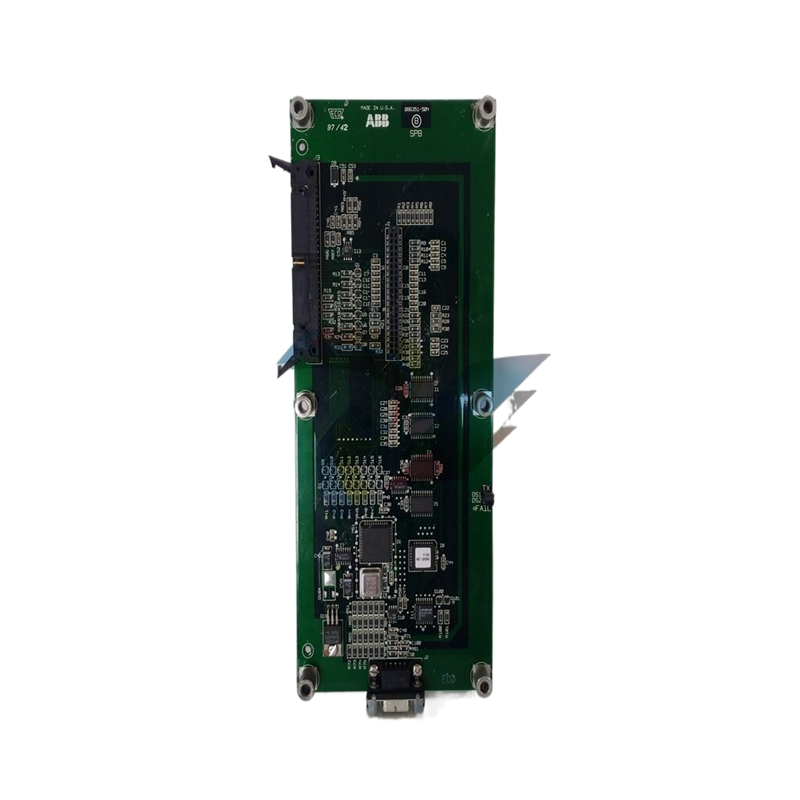

ABB H&B Contronic SL 13 (SL13) Module SL 13 H&B Contronic

Basic Information

Appearance and structure: It usually adopts a standard industrial module form factor design with a robust housing, which may be made of metal or high-quality engineering plastics, with good resistance to electromagnetic interference, dust, water and chemical corrosion. They are generally clearly labelled with the words ‘SL 13’ and ‘ABB H&B Contronic’ for easy identification. The compact dimensions allow mounting in the control cabinet on standard DIN rails for easy system expansion and maintenance.

Weight: The exact weight is not yet known, but is generally moderate, does not overburden the installation structure and ensures stability during operation.

Technical parameters

Power requirements: usually work under 24V DC power supply, and can adapt to a certain range of voltage fluctuations, such as between 20V and 30V DC, to ensure that the industrial site power supply instability can still be stable operation.

Input and output channel characteristics: The module is equipped with multiple digital and analogue input and output channels. The digital input channels can receive discrete signals from digital sensors or other digital devices, such as proximity switches, photoelectric switches, etc., with 0V or 24V indicating the on/off state. The digital output channel outputs digital signals for controlling actuators such as relays and contactors. The analogue input channel can receive continuously changing analogue signals generated by sensors such as temperature, pressure, flow, etc. The common signal range is 0-10V or 4-20mA and other standard industrial analogue signals, and the analogue output channel can output analogue signals for controlling equipment requiring continuous adjustment, such as regulating valves, inverters and so on.

Communication interface: Supporting a variety of industrial communication protocols, such as Profibus, Modbus, industrial Ethernet, etc. Through these communication interfaces, the module can exchange data and communicate with other ABB equipment and third-party industrial equipment, to achieve the collaborative work of the entire industrial automation system.

Functional features

Signal processing function: the input digital and analogue signals can be collected, filtered, amplified and other processing operations, to ensure accurate reading and high quality transmission of signals, but also signal conversion, to meet the demand for signal compatibility between different devices.

Control Function: Rich control logic functions are integrated internally, which can be flexibly set through programming software or configuration tools to realise various complex control strategies, such as logic operation, timing control, counting control, etc., and can be used to precisely control the equipment and processes in industrial production process.

Diagnostic and Alarm Function: With powerful self-diagnostic function, it can monitor its own working status and operating parameters in real time, including power supply voltage, working temperature, input/output channel status and communication status, etc. In case of any abnormality, it can send the fault information to the upper computer or other monitoring devices through the communication interface, and send out intuitive alarm signals through the indicator light or buzzer locally.

Application Fields

Industrial automation production line: It is widely used in automation production line in automobile manufacturing, electronic equipment production, machining and other industries, such as controlling robot movement, conveyor belt speed, tightening tool torque, etc., to improve production efficiency and product quality.

Process control industry: in the chemical, pharmaceutical, food and beverage, sewage treatment and other process control industry, used in the production process of a variety of physical quantities for measurement and control, such as temperature, pressure, flow, level, etc., to ensure the stability of the production process and product quality.

Energy management system: in the field of energy supply and management such as electric power, heat, gas, etc., it can be used to monitor and control the energy production equipment, transmission equipment and metering equipment, to achieve optimal distribution and management of energy, to improve the efficiency of energy utilisation, and to guarantee the reliability of energy supply.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923