K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

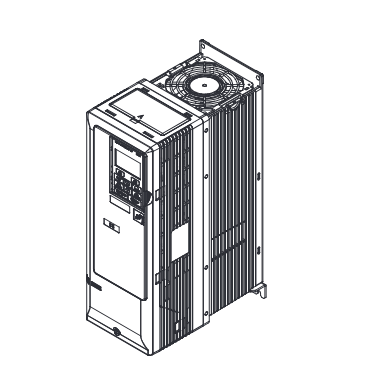

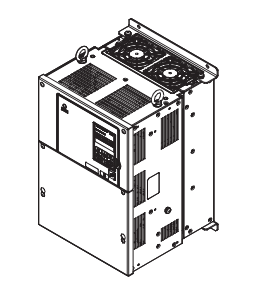

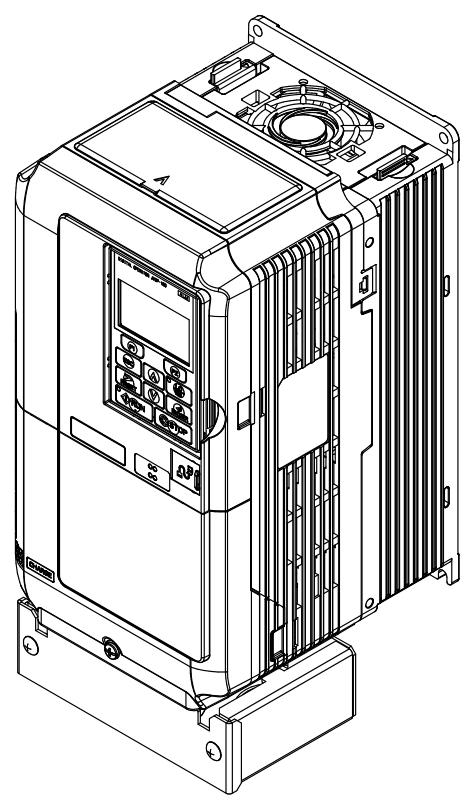

ABB ACQ580-01 Hardware Automatic control system

ABB ACQ580-01 Hardware Automatic control system

Product overview

One purpose of this supplement is to provide information for the two ratings: 125 and 150 HP at 230V. These ratings are built in the R9 drive frame. They are only available in North America and have cULus listing. They do not have certifications for use in other parts of the world.

SPECIFICATION

•The following temperature profile is used in safety value calculations:

– 670 on/off cycles per year with T = 71.66 °C

– 1340 on/off cycles per year with T = 61.66 °C

– 30 on/off cycles per year with T = 10.0 °C

– 32 °C board temperature at 2.0% of time

– 60 °C board temperature at 1.5% of time

– 85 °C board temperature at 2.3% of time

• The STO is a type A safety component as defined in IEC 61508-2.

• Relevant failure modes:

– The STO trips spuriously (safe failure)

– The STO does not activate when requested

• A fault exclusion on the failure mode "short circuit on printed circuit board" has been made (EN 13849-2, table D.5). The analysis is based on an assumption that one failure occurs at one time. No accumulated failures have been analyzed.

• STO response times:

– STO reaction time (shortest detectable break): 1 ms

– STO response time: 2 ms (typical), 5 ms (maximum)

– Fault detection time: Channels in different states for longer than 200 ms

– Fault reaction time: Fault detection time + 10 ms

• Indication delays:

– STO fault indication (parameter 31.22) delay: < 500 ms

– STO warning indication (parameter 31.22) delay: < 1000 ms

Product and service inquiries

Address any inquiries about the product to your local ABB representative, quoting the type designation and serial number of the unit in question. A listing of ABB sales, support and service contacts can be found by navigating to abb.com/ searchchannels.

Product training

For information on ABB product training, navigate to new.abb.com/service/training. Providing feedback on ABB Drives manuals Your comments on our manuals are welcome. Navigate to new.abb.com/drives/manuals-feedback-form. Document library on the Internet You can find manuals and other product documents in PDF format on the Internet at abb.com/drives/documents.

Hardware automatic control system function

Built-in control for pump applications

•The ACQ580-01 has built-in specialised pump control functions for the water industry, which are designed to ensure that the pumping system operates in a stable manner, thus reducing energy bills.

•By avoiding pressure spikes, the service life of water pipes and pumping systems is extended.

Level control function

•Level control function can be used to control water levels in tank fill or emptying applications.

•Cascade operation of up to eight pumps is supported, in keeping with the IPC Smart Pump function.

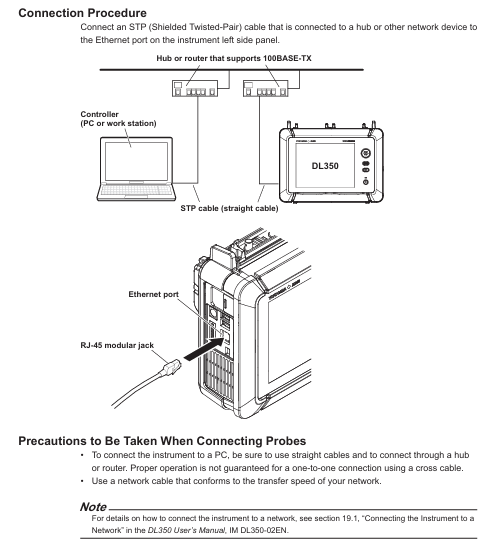

•The frequency converter communicates via I2I based on the built-in fieldbus EFB interface for precise control.

•When the actual liquid level reaches the start level of the pump, the system automatically starts the corresponding pump; when the liquid level reaches the stop condition, the pump stops running.

APPLICATIONS

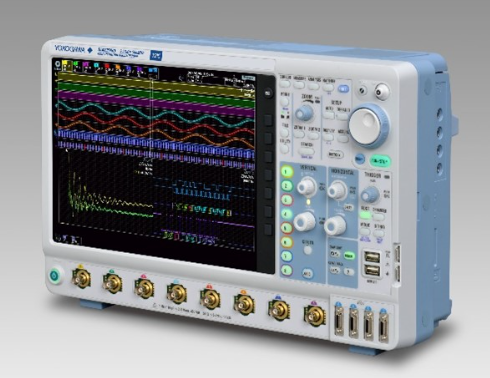

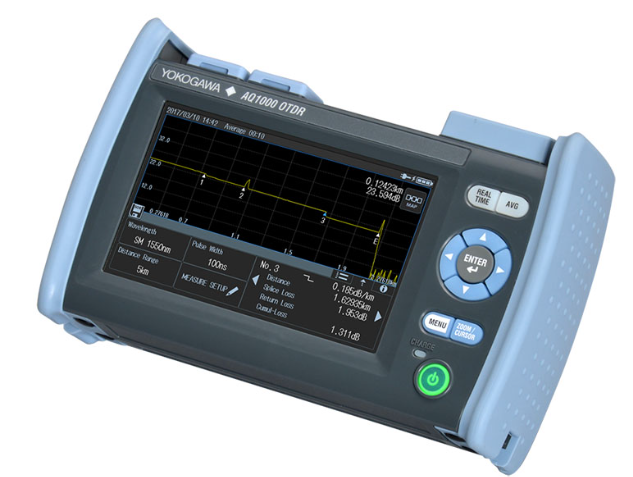

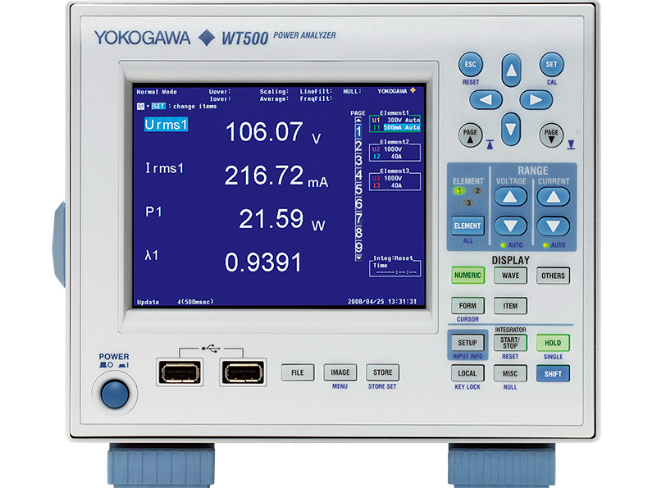

• Simulation

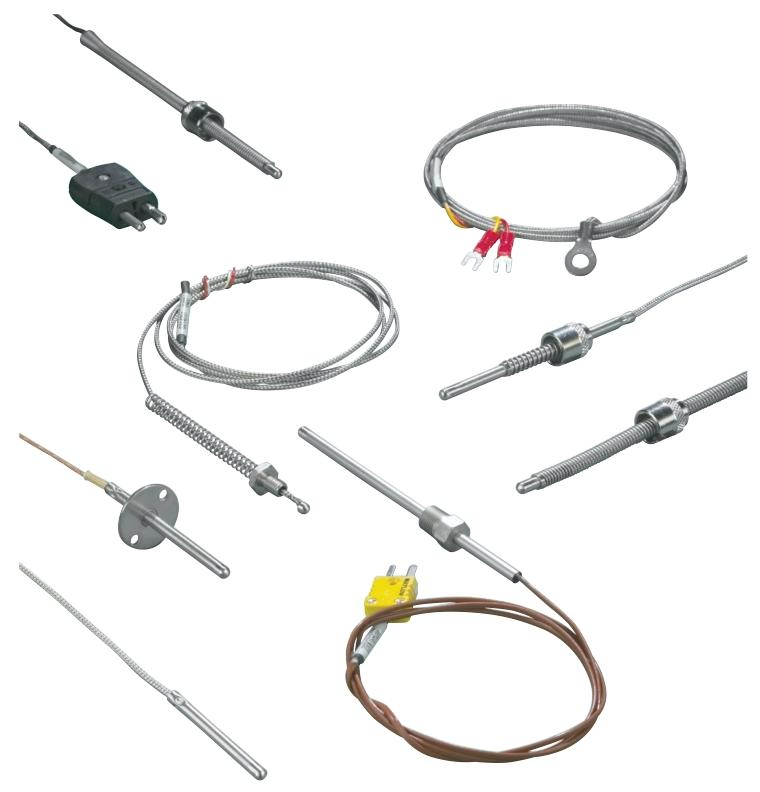

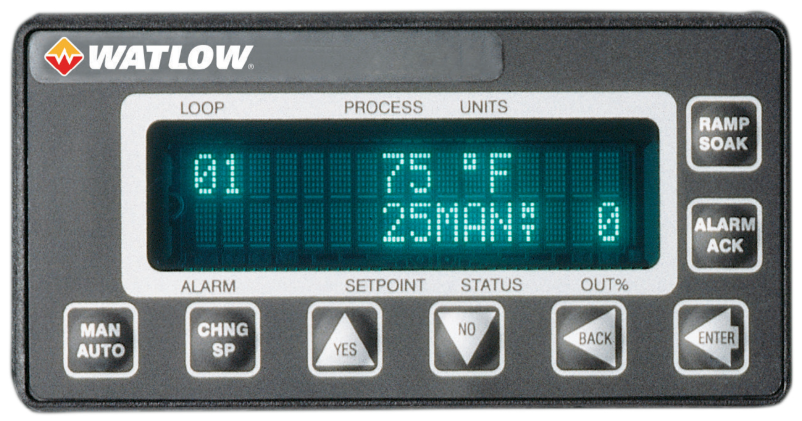

• Instrumentation

• Industrial control

• Process control and monitoring

• Factory automation

• Intelligent networked PLC controllers

• Automated test

• Data acquisition

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|