K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

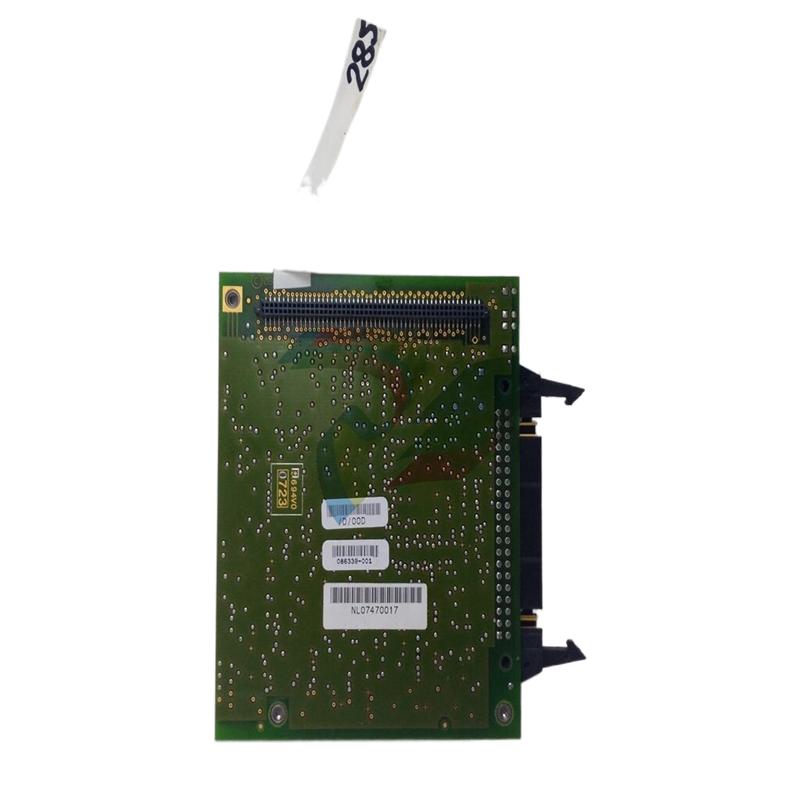

ABB SPCMM11 Condition Monitoring Module

Overview

Product Definition and Usage: ABB SPCMM11 Condition Monitoring Module is an important module developed by ABB for condition monitoring of industrial equipment. It is mainly used for real-time collection and analysis of various parameters during the operation of industrial equipment (such as motors, pumps, fans, etc.), so as to detect possible failures or abnormalities in the equipment in advance, and to provide key data support for preventive maintenance, ensure the reliable operation of the equipment, and prolong the service life of the equipment.

Working Principle

Signal Acquisition Process: The module is equipped with a variety of input interfaces that can receive signals from different sensors. These sensors include, but are not limited to, vibration sensors, temperature sensors, current sensors and pressure sensors. For example, vibration sensors can detect the vibration amplitude, frequency and other information of the equipment; temperature sensors can measure the temperature of key parts of the equipment. When these sensors transmit analogue signals (e.g., 4-20mA current signals, 0-10V voltage signals) to the module, the analogue-to-digital conversion (A/D) circuitry inside the module converts the analogue signals to digital signals for subsequent processing.

Data analysis and feature extraction: The converted digital signals enter the module's microprocessor. The microprocessor runs complex data analysis algorithms to analyse the signal in the time and frequency domains. In time-domain analysis, it can obtain parameters such as the peak value, mean value and RMS value of the signal; in frequency-domain analysis, the frequency components and energy distribution of the signal are determined through algorithms such as Fast Fourier Transform (FFT). For example, through the frequency domain analysis of motor vibration signals, characteristic frequencies such as motor rotor imbalance, misalignment, bearing failure, etc. can be identified, so as to determine the operating status of the motor. At the same time, the module can also extract other features of the signal, such as the trend of the waveform, harmonic content, etc., for a more comprehensive assessment of the state of the equipment.

Fault Diagnosis and Alarm Mechanism: Based on the pre-set fault diagnosis rules and thresholds, the module compares the data obtained from the analysis with the standard data under normal operating conditions. When one or some parameters are found to be out of normal range, the module will trigger an alarm signal. The alarm signal can be output in various ways, such as digital output interface to control external alarms, or through the communication interface to send the alarm information to the upper computer monitoring system. In addition, the module can also assess the severity of the fault, according to the different severity of the alarm issued by different levels, so that maintenance personnel can take timely action.

Performance features

Multi-parameter monitoring capability: capable of simultaneously monitoring a variety of equipment operating parameters, such as vibration, temperature, current, pressure and so on. This integrated multi-parameter monitoring can reflect the operating status of the equipment in a more comprehensive way, avoiding the misjudgment that may be caused by single-parameter monitoring. For example, for motor monitoring, the combination of vibration and temperature parameters can more accurately determine whether the motor has bearing wear, overload and other problems.

High-precision signal processing and analysis: high precision in signal processing and analysis. the A/D conversion accuracy can reach ±0.1% - ±0.5% full-scale accuracy, and the data analysis algorithm can accurately extract various features of the signal. This makes it possible to detect small changes in the operating status of equipment, which helps in the early detection of potential faults. For example, small changes in vibration frequency can be accurately identified, thus providing early warning of possible equipment failure.

Flexible Configuration and Adaptability: It can be flexibly configured according to different equipment types and monitoring needs. Users can adjust the module's input parameters (e.g., sensor type, signal range, etc.), analysis algorithms (e.g., parameter settings for time-domain and frequency-domain analyses), and alarm thresholds, etc., either through software settings or hardware jumpers. This flexibility makes it adaptable to a variety of industrial equipment and complex monitoring scenarios.

Remote monitoring and communication function: It has a powerful communication function and supports a variety of industrial communication protocols, such as Industrial Ethernet, Modbus, Profibus, etc.. This makes it possible to transmit monitoring data and alarm information in real time to the remote host computer monitoring system or the mobile terminal of maintenance personnel. Through remote monitoring, the maintenance personnel can know the operation status of the equipment at anytime and anywhere, deal with alarm events in time, and improve the efficiency of equipment maintenance.

Technical Parameters

Input parameters

Number of Analogue Input Channels: Usually there are multiple analogue input channels, the number of which may vary from 4 - 16, depending on the module model. These channels are used to connect to various sensors and collect equipment operating parameters.

Input signal type and range: A wide range of analogue signal types are supported, such as voltage signals (- 10V - + 10V, 0 - 10V, etc.) and current signals (4 - 20mA, 0 - 20mA, etc.). Signals from different sensors can be received to suit various equipment monitoring needs.

Input signal resolution: For analogue input signals, resolutions of 12 - 16 bits are possible, which ensures highly accurate acquisition of input signals.

Processing parameters

A/D Conversion Accuracy: The conversion accuracy is ±0.1% - ±0.5% full scale accuracy, which ensures the accuracy of signal conversion.

Data analysis algorithms: Includes a variety of algorithms such as time domain analysis (e.g. calculation of peak, mean, RMS, etc.) and frequency domain analysis (e.g. FFT algorithm), which are used to comprehensively analyse the operating parameters of the equipment. The frequency resolution of frequency domain analysis can reach 0.1Hz - 1Hz, depending on the sampling frequency and data length.

Output parameters

Number and type of digital output channels: A certain number of digital output channels are available for controlling external alarms or other devices. The digital output signals can be TTL (Transistor - Transistor Logic) level or CMOS (Complementary Metal Oxide - Semiconductor) level, and the output current is able to meet the needs of driving external devices (e.g., small alarms, indicator lights, etc.).

Communication interfaces and protocols: Supports a variety of industrial communication protocols, such as Industrial Ethernet (communication rates up to 10Mbps - 1000Mbps), Modbus (communication rates between 9600bps - 115200bps), Profibus (communication rates up to 12Mbps - 100Mbps), etc., for data transmission and remote monitoring.

Physical Parameters

Dimensions: The external dimensions are generally designed according to the installation requirements, the length may be between 15cm - 30cm, the width between 10cm - 20cm, the thickness between 5cm - 10cm, which is easy to be installed in the control cabinet or the monitoring position of the equipment.

Weight: The weight is usually between 1kg - 3kg, which will not cause too much burden on the installation and structure of the equipment.

Environmental Parameters

Operating temperature range: can work in a wide temperature range, generally - 20 ℃ - + 60 ℃, can adapt to different industrial site temperature conditions.

Humidity range: The relative humidity range is usually 10% - 90% (non-condensing), ensuring normal operation in different humidity environments.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923