K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

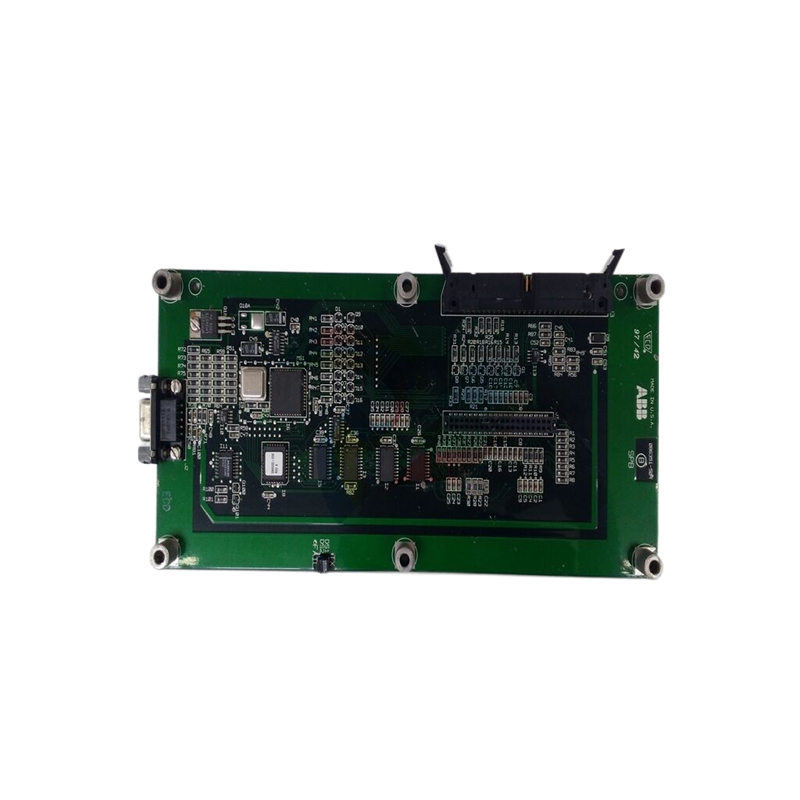

ABB SPDSI14 DSI14 Digital Input Module

Overview

Product Definition and Function: The ABB SPDSI14 DSI14 Digital Input Module is a module designed by ABB for industrial automation control systems to receive and process digital input signals. It is responsible for converting digital signals (e.g. on/off signals, pulse signals, etc.) generated by external devices (e.g. sensors, switches, etc.) into recognisable digital levels within the module and transmitting these signals to the control system for subsequent logical judgements, control decisions and other operations.

Working Principle

Signal reception and conditioning: The module has several digital input channels, usually 14 channels. These channels can receive many types of digital signals, such as signals from proximity switches, photoelectric switches, limit switches and other devices. When an external digital signal is connected to the module's input channels, it first passes through a signal conditioning circuit. This circuit mainly performs filtering, level conversion and buffering on the signal. Filtering is to remove high-frequency noise and interference components in the signal to ensure the purity of the input signal; level conversion is to convert the level of the external signal to the standard level that can be processed within the module, for example, to convert external signals of different voltage levels to a unified logic level within the module (such as TTL or CMOS levels); buffering is to enhance the driving ability of the signal to ensure that the signal can be stably Buffering enhances the driving capability of the signals to ensure stable transmission to the subsequent circuits.

Signal Detection and Conversion: The conditioned signal is fed into the signal detection circuit. This circuit detects the level state (high or low) of the signal and converts it into a digital logic signal (e.g. ‘1’ for high level, ‘0’ for low level). For pulsed signals, the rising and falling edges of the pulse can also be detected and operations such as counting or time measurement can be performed. For example, when a proximity switch detects an object approaching and outputs a high level signal, the module's signal detection circuit will convert this high level to a digital ‘1’ and store this signal state in an internal register.

Data transmission and communication: The converted digital signals are stored in the internal registers of the module, and then these signals are transmitted to the control system through the communication interface. The module supports a variety of communication protocols, such as Industrial Ethernet, Profibus, Modbus, etc., which enables good data interaction with different control systems. The control system processes the received digital signals accordingly, such as starting and stopping the motor according to the switching signal, or calculating the running speed of the equipment according to the pulse signal.

Performance features

High Reliability Signal Acquisition: It has high reliability in the signal acquisition process and can effectively resist the interference in the industrial environment. Its signal filtering function can remove most of the electromagnetic interference (EMI) and radio frequency interference (RFI), to ensure that the collected signal is true and reliable. At the same time, the level conversion and buffer processing of the signal conditioning circuit also improves the stability of the signal and reduces false judgements caused by signal fluctuations.

Multi-Channel Input Design: The design of 14 digital input channels makes it possible to receive multiple digital signals at the same time, which facilitates the status monitoring of multiple external devices. For example, in an automated production line, multiple sensors can be connected at the same time to detect the position of equipment, the presence or absence of materials and other status, thus realising comprehensive monitoring of the entire production line.

Flexible Signal Processing Capability: Supports multiple types of digital signal processing, not only for simple switching signals, but also for pulse signals. For pulse signals, operations such as counting, frequency measurement, and period measurement can be performed. This flexibility allows it to adapt to different industrial application scenarios and meet diverse control needs.

Fast Response Characteristics: With fast response time, it is able to detect changes in the input signal and transmit them to the control system in a short period of time. The response time is generally within a few milliseconds (ms), which is very important for industrial control scenarios that require fast response (such as emergency stop systems, high-speed counting equipment, etc.) to ensure that the system responds in a timely manner.

Technical Parameters

Input parameters

Number of input channels: 14, each channel can receive digital signals independently.

Input Signal Type and Level Range: A wide range of digital signals can be received, including, but not limited to, TTL (Transistor Transistor Logic) level signals, CMOS (Complementary Metal Oxide Semiconductor) level signals, and dry contact signals (e.g., on/off signals for switches). For level ranges, TTL level signals generally have a high level range of 2V - 5V and a low level range of 0V - 0.8V; CMOS level signals have a high level range and a low level range that vary according to the specific CMOS device, but are usually in a similar range; dry contact signals do not have strict level requirements, as long as they can form an effective on/off state.

Signal Processing Parameters

Signal Filtering Characteristics: It has the function of filtering, which can filter out the high-frequency interfering signals, and the frequency range of filtering can be set according to the user's demand, and it can usually filter out the interfering signals with the frequency higher than a few kilohertz (kHz).

Pulse Processing Capability: For pulse signals, it can perform counting, frequency measurement and period measurement. The counting accuracy can reach ±1 pulse, the frequency measurement accuracy can reach ±0.1% - ±0.5% reading accuracy, and the cycle measurement accuracy can also reach a high level, generally within the range of ±0.1% - ±0.5% cycle reading accuracy.

Communication Parameters

Supported communication protocols: Support a variety of industrial communication protocols, such as Industrial Ethernet (Ethernet/IP), Profibus, Modbus, etc., to facilitate integration with different control systems.

Communication rate: The communication rate varies depending on the protocol. For example, in industrial Ethernet communication, the communication rate can reach 10Mbps - 1000Mbps; in Profibus communication, the communication rate can reach 12Mbps - 100Mbps; in Modbus communication, the communication rate can vary from 9600bps - 115200bps.

Physical Parameters

Dimensions: The external dimensions are generally designed according to the installation requirements, the length may be between 10cm - 20cm, the width between 5cm - 10cm, the thickness between 3cm - 8cm, which is easy to be installed in the standard card slot of the control cabinet or the installation position of the equipment.

Weight: Light weight, usually between 100g - 500g, will not cause excessive burden on the overall weight and installation of the equipment.

Environmental parameters

Operating temperature range: can work in a wide range of temperature, generally - 20 ℃ - + 60 ℃, can adapt to different industrial site temperature conditions.

Humidity range: The relative humidity range is usually 10% - 90% (non-condensing), ensuring normal operation in different humidity environments.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923