K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

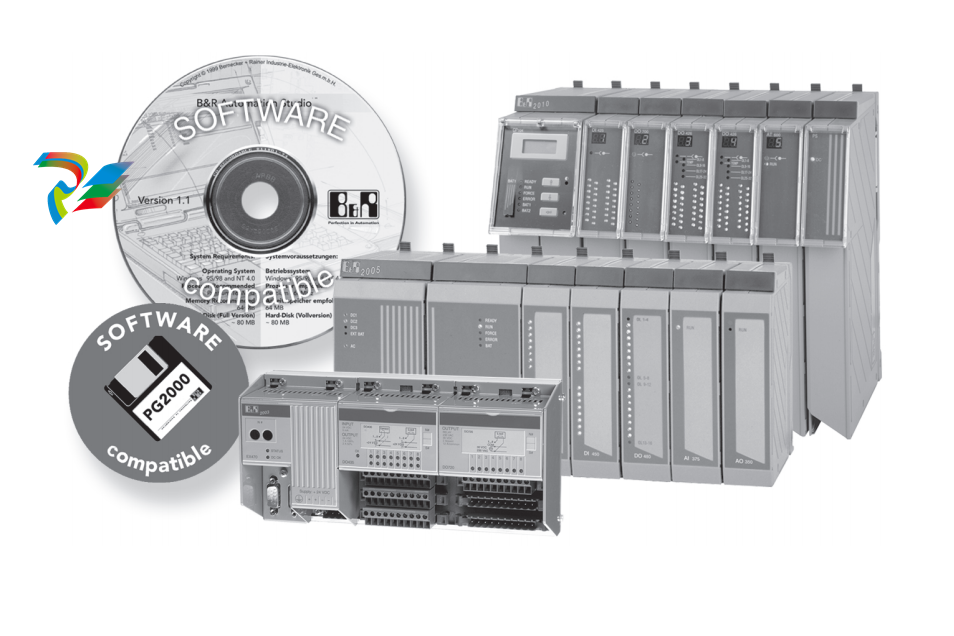

The B&R SYSTEM 2000 controller generation is an automation system which sets new standards for

performance, functionality and operational security.The B&R 2003, B&R 2005 and B&R 2010 systems

cover the entire application range, from simple logic controllers to complex decentralized automation

systems.

The systems have different structures, expandability, modularity and CPU performance. These systems are

very closely related and therefore meet the fundamentalrequirements for complete centralized and

decentralized compatibility for the programmer.

B&R-X20CPx48x-ENG-controller generation is

B&R SYSTEMS2003 Characteristics

Hardware:

Hardware modularity

Network capable

Communication interfaces to HMI

PCC and industrial computer functionality

EMC according to IEC 61131-2

Secure I/O bus protocol

Remote I/O points

Bit or word processing in a single cycle

All terminals for 2 or 3 line connection available directly on the module

No extra terminals needed

Software:

Multitasking operating system for PCC and industrial computer applications

Powerful PCC programming languages

High level language programming

Exact control over PCC timing

Simple programming software with window oriented user interface

●Project management using the programming software

PCC (programmable computer controller)

The core of the PCC consists of powerful standard computer components. The processors are supported by

RISC processors which allow fast processing of I/O signals.

Most CPUs use a modular interface concept Various bus or network systems can be integrated in the B&R

SYSTEM 2003 efficiently using plug-in interface modules.

The computer core uses components which provide the functionality of an industrial PCC. Bit, byte and word

access ispossible inasinglecycle whichincreasesspeed whencombiningPCC links andindustrial computer

functionality.

System Interface

The system interface is the sum ofall l/O modules, i.e. the interface between PCC and the machine/system

being controlled. All B&R SYSTEMS 2003 I/O modules are protected from extemal disturbances using

suitable EMC measures(IEC 61131-2 standard).

Length and structure of the l/O bus can be adjusted according to the requirements of the machine/system.

Thatmeansthe connectionpoints forI/O signals donothave tobe in the same location asthePCC CPU.Using

remote l/O bus segments (Remote I/O,CAN I/O) allows the optimal structure to be created for the respective

application. I/O modules are installed on the machine/system where they are needed. Cabling tothe core of

the PCC is reduced to a two conductor or fibre optic cable.

Network Capability

Network capability and the possibility to communicate with systems from other manufacturers have become

amustforall industrialcontrollers. TheB&R2000PCC familymeets manyof these requirements using system-

wide and multi-system communication possibilities.

Software Concept

Special attention was given to simple operation and programming.Standard PLC programs run cyclically, i.e.

the program is repeated in a loop. To increase efficiency, the B&R SYSTEM 2000 also offers the possibility

to use various tasks with different cycle times. In this way, critical program sections (e.g.reaction to trigger

signals) can be processed faster than the evaluation of slower events (e.g. polling keys).

Programming

The CPU is programmed using the programming systemPG2000 or Automation Studio™. Several program-

ming languages are available:

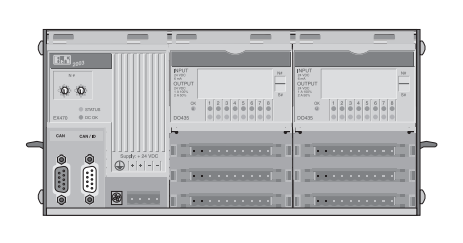

2.3 SUPPLY VOLTAGE

The supply voltage for the B&R 2003 control system is provided by a power supply integrated in the

controller.

2.4 TERMINAL BLOCKS

B&R 2003 modules use a large number of terminal blocks to make connections.

The pin assignments for the individual modules can be found in this manual (Chapter "B&R 2003 Modules").

The construction of the terminal blocks has the following advantages for the PCC user:

.Terminal blocksare easy to remove using two ejection leverson the module ordirectly ontheterminal

blocks.

·Most terminal blocks are available with screw clamps and also with cage clamps.

2.5 PROGRAM MEMORY MODULES

2.5.1 2003 PCC CPU

When using aB&R 2003 CPU,application programs and the operating system are stored in the CPU.

2.5.2 Remote Slaves

When used asa remote l/Oslave, the application programs are stored in the remote master (e.g.EX150).The

operating system is programmed in the remote I/O bus controller.

2.5.3 CAN Slaves

When used as a CAN slave,the application programs are stored in theCAN master (e.g.XP152).The

operating system is programmed in theCAN buscontroller. Configurationdatacanbeplaced inconfiguration

memory (inserted from the front).

The CAN bus controller EX270 is equipped with an internal S-EEPROM. Operating system parameters can

be stored in this S-EEPROM.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923