Honeywell Digital Output, 120/240 VAC (8 channel) 900H03-0202

Redundant CPUs - Redundancy is provided by two C75 CPUs operating in a controller rack; this rack has noI/O. A Redundancy switch module (RSM) sits between the CPUs.

Redundant CPU Power - Two power supplies, P01 and P02 one for each C75 CPU. Model numbers are 900P01-

0101, 900P01-0201, 900P02-0101, 900P02-0201

Redundant CPU-I/O connection – Each CPU has its own 100 base-T Ethernet physical communication link with

one or more racks of I/O. Multiple I/O racks require Ethernet switches.

I/O racks – 5 racks shown, top to bottom: 4-slot w/1 power supply, 8-slot w/1 power supply, 12-slot w/1 power

supply, 8-slot w/redundant power supplies, 12-slot w/redundant power supplies. A Power Status Module (PSM) is

required with redundant power supplies. High and low capacity power supplies are available.

Dual Networks for Host communications - Dual Networks for Host communications are provided on the C75 CPU.

Both network ports are continuously active on the Lead controller. The network ports on the Reserve CPU are not

available for external communications. Experion HS and the 900 Control Station (15 inch model) support Dual

Ethernet communications and automatically transfer communications to the opposite E1/E2 port during a network

failure. Connections to these ports are to be considered part of the control network layer and as such care must be

taken to reduce exposure to uncontrolled/ unknown network communications. A properly configured firewall such as

the MOXA EDR-810 is recommended to help mitigate the exposure.

Scanner 2 module – has 2 ports, one for each CPU connection to I/O. This IO network between the controllers

and scanners is considered proprietary with no other Ethernet traffic.

Feature Summary

Hardware

Modular rack structure; components are ordered individually as needed

CPU with Ethernet and isolated RS485 communications

Easy to assemble, modify, and expand

C30 and C30S controllers provide local I/O connections while C50/C70 and C50S/C70S Controllers provide for

remote input/output rack connections over a private Ethernet-linked network

Parallel processing - a microprocessor in each I/O module performs signal processing, to preserve update rates

Power supplies - provide power to CPU rack and Scanner I/O racks

Redundancy

Redundant C75 CPU

Redundancy Switch Module (RSM) – required between redundant CPUs

Redundant Power Supply – provides redundant power to any CPU rack or Scanner2 I/O rack

Power Status Module (PSM) – required when using a second power supply in Scanner2 I/O rack

Communications

All CPUs (except where noted):

Serial Ports:

Legacy

Two serial ports, configurable for RS-232 or galvanically isolated RS-485 communications.

RS232 port can be used for link to PC for 900 Designer configuration tool (up to 50ft/12.7 Meters)

or via modem. Also can be configured for Modbus RTU, master or slave.

RS 485 port used for 2 wire link to legacy operator interface (ELN protocol) or can be configured

for Modbus RTU, master or slave communications (up to 2000 Ft /600 Meters).

New Controllers

Two isolated RS 485 communications ports

USB to RS485 cable must be obtained to support link to PC for 900 Designer configuration tool

Can be configured for Modbus RTU, master or slave communications (up to 2000 Ft /600 Meters)

Ethernet 10/100 Base-T connection:

Port(s) configured to Auto Negotiate - default to half duplex

C30/C30S controller up to 5 PC hosts via Modbus/TCP protocol. C50/C50S, C70/C70S and

C70R Legacy and C75/C75S (new model) support up to 10 PC hosts via Modbus/TCP protocol.

Peer-to Peer (UDP) communication with up to 32 other HC900 Controllers.

C70/C70S and C70R Legacy and C75/C75S (new model) have 2 Ethernet ports for connection to

up to 10 PC hosts. They also support Modbus/TCP Initiator function over both ports and

automatically switch between ports to maintain Peer to Peer communications with other

C70/C70S or C70R/C75/C75S redundant CPUs.

Private Ethernet 100 base T connection to I/O expansion racks: (except C30 and C30S CPU)

Direct connection to each C70R Legacy and C75/C75S (new model) CPU.

For more information

For complete feature summary and specifications see Specifications on page 206.

Components and Architecture

Overview

This section provides a description of each of the major components that can be included in an HC900 Controller

physical configuration, and indicates some of the methods by which they can be combined.

Components

The Honeywell HC900 Process Controller includes a set of hardware modules that can be combined and configured

as required for a wide range of small to medium process control applications.

Some of the modules are required in all configurations. Others are optional; they are selected as appropriate to

provide optional functions and/or to "size" the system, either in initial planning, or in modifying and/or expanding

the system to meet changing requirements.

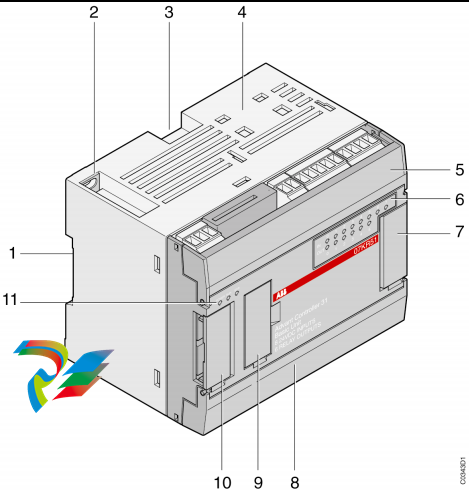

An HC900 Controller configuration with multiple controllers is illustrated in Figure 4.

This illustration includes key-numbers that identify components that are described in Table 2

CAUTION

The HC900-expansion I/O link is a private network and the switch used for the interconnection of the

HC900 Processor and Scanners must not be connected to any other LAN or WAN. Likewise, no devices

other than the HC900 components should be connected to the I/O link Switch. Failure to comply will

cause communication failures on the I/O link causing I/O modules to go in and out of their failsafe

settings.