K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

WARNING notices as used in this instruction apply to hazards or unsafe practices that could result in

personal injury or death.

CAUTION notices apply to hazards or unsafe practices that could result in property damage.

NOTES highlight procedures and contain information that assists the operator in understanding the

information contained in this instruction.

ABB IMFEC11 Analog Input Module

SECTION 1 - INTRODUCTION

OVERVIEW

The IMFEC12 High Level Analog Input (FEC) module inputs 15

channels of analog signals only to the multifunction processor

(MFP) or multifunction controller (MFC) module.

The IMFEC11 High Level Analog Input (FEC) module inputs 15

channels of analog or frequency shift keyed (FSK) digital signals to the MFP or MFC module. The IMFEC11 module performs all the functions of the IMFEC12 module and also

provides communication with the Bailey-Fischer & Porter line

of FSK digital smart transmitters and other smart devices in a

field bus or point-to-point configuration.

Figure 1-1 shows how the FEC module fits within the INFI 90

OPEN system.

INTENDED USER

Installation and application personnel should have a solid

background in electronic instrumentation and process control.

They should be familiar with proper grounding and safety procedures for electronic instrumentation. Operators should have

a knowledge of the process and should read and understand

this instruction before placing the module in operation.

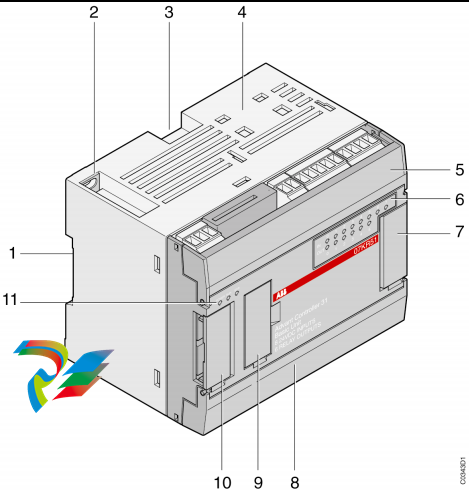

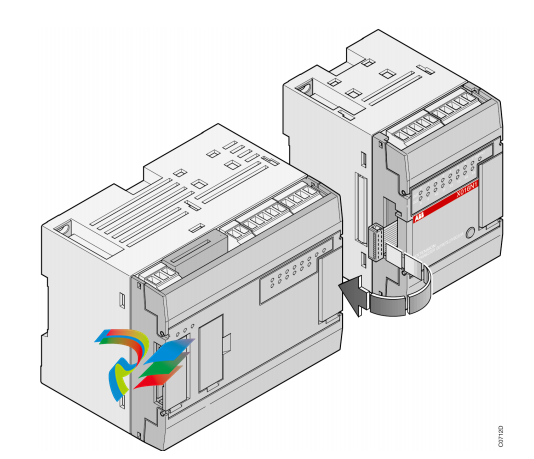

HARDWARE DESCRIPTION

The FEC module is an intelligent module, with on-board microprocessor, memory, analog-to-digital converter and communication circuitry. The module is a single printed circuit board

that occupies one slot in a module mounting unit (MMU). Two

captive latches on the module faceplate secure it to the module

mounting unit.

The module has three card edge connectors for external signals

(transmitter inputs and communication), system communication (I/O expander bus) and power. The module receives input

through a cable connection to a termination unit (TU) or termination module (TM). Wiring from the field devices connect to

terminal blocks on the termination unit or termination module. The IMFEC11 circuit board has 18 jumpers; three jumpers

that allow selecting the mode of operation and communication

(J2, J3 and J4) and 15 jumpers that select voltage/current

input (J6 through J20). A dipswitch setting (S1) holds the I/O

expander bus address of the module.

Figure 1·1. INFI 90 OPEN Communication Levels

The IMFEC12circuit board only uses one working setting,

dipswitch S1 that holds the I/O expander bus address of the

module. Jumpers J2 through J4 and J6 through J20 are notused.

HARDWARE APPLICATION

The FEC module interfaces analog and digital signals from field

devices to the MFP or MFC module. The IMFEC1l module can

interface Bailey-Fischer & Porter FSK smart transmitters and

other smart devices. The IMFEC12 is for use with conventional

transmitters (BC, Eg and PT) and standard analog inputs.

The IMFEC11 module can operate in one of two modes:FSK

field bus mode or FSK analog point-to-point mode. In the FSK

field bus mode, a single two-wire input (bus) links a maximum

of 15 FSK smart transmitters. All inputs (process data and

module to transmitter communication) are in the frequency

shift keyed format and share the field bus. Refer to the

NTFBO1 Field Bus Termination Unit instruction for specific

limitations on field bus communications. All field devices must

be Bailey-Fischer & Porter when using this mode.

In the FSK analog point-to-point mode, the IMFEC11 module

can interface up to 15 discrete analog process inputs from FSK

smart devices and communicate (digitally) with those devices.

Additionally, the IMFEC11 module can interface a mixture of

conventional transmitters and other external analog inputs

while operating in this mode. These devices can input only pro cess data to the FEC module; they cannot communicate to the

module. In point-to-point operation, each device is individually

wired to the analog input termination unit or module.

FEATURES

The design of the FEC module, as with all INFI 90 OPEN mod ules, allows for flexibility in creating a process management

system. The module supports Bailey-Fischer & Porter FSK dig ital smart transmitters and other smart devices, conventional

transmitters and standard voltage or current inputs.

The FSK digital capability (IMFEC11) eliminates conversion

errors and increases process control accuracy. Access is

always available to the real time process status. In the field bus

mode, all information (including the process variable) is trans mitted digitally between the FEC module and the field devices.

The FEC module stores process data, control commands and

transmitter configuration data in memory. It works to restore

communication with a transmitter if a communication failure

occurs. Upon restoring communication with a failed transmit ter, the FEC module checks the transmitter configuration

before the control module (MFP/MFC) resumes updating the

process control.

INSTRUCTION CONTENT

This instruction consists of eight sections and three

appendices.

Introduction Overviews the FEC module. It contains features, a description,

reference documents and specifications.

Description and

Operation

Explains the theory of module operation.

Installation Covers handling precautions, switch and jumper settings,

installing and checking the FEC inputs.

Operating Procedures Explains how to start up and operate the FEC module.

Troubleshooting Describes how to monitor transmitter errors from the status

reports. It explains how to check for FEC errors and the correc tive action to take.

Maintenance Contains a maintenance schedule for the FEC module.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923