K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

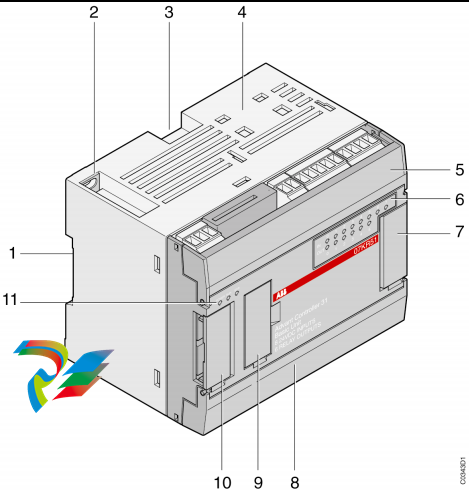

The REF601 is a dedicated feeder protection and control relay.

The REJ601 is an overcurrent protection relay without breaker

control. These relays are intended for the protection of utility

substations and industrial power systems within primary and

secondary distribution networks. They are members of ABB’s

Relion® product family and part of its 605 series.

ABB REF601 Feeder protection and control

1. Description

The REF601 is a dedicated feeder protection and control relay.

The REJ601 is an overcurrent protection relay without breaker

control. These relays are intended for the protection of utility

substations and industrial power systems within primary and

secondary distribution networks. They are members of ABB’s

Relion® product family and part of its 605 series.

These relays, provide an optimized composition of protection,

monitoring and control functionality in one unit, with the best

performance usability in its class and are based on ABB’s in depth knowledge of protection and numerical technology.

2. Relay functions

The REF601 and REJ601 can be pre-configured which facilita tes easy and fast commissioning of switchgear.

To emphasize the simplicity of using these relays, only applica tion specific parameters need to be set within the relay’s inten ded area of application. The standard signal configuration can

be altered by LHMI (local human-machine interface).

The relays are available in three alternative application configu rations, as indicated in Table 2.

Table 1. Standard configurations

Description Relay type

Feeder protection and control REF601

Overcurrent/Feeder protection REJ601

Table 2. Application configurations and supported functions

REJ601/ REF601 REJ601/ REF601 REF601

Functionality ANSI IEC B C D

Protection

Non-directional overcurrent protection, low-set stage 51P 3I> ● ●●

Non-directional overcurrent protection, high-set stage 50P-1 3I>> ● ●●

Non-directional overcurrent protection, instantaneous stage 50P-2 3I>>> ● ●●

Ground-fault protection, low-set stage 51N Io> ● ●●

Ground-fault protection, high-set stage 50N Io>> ● ●●

Three-phase transformer inrush detector 68 3I2f> ● ●●

Three-phase thermal overload protection for feeders, cables and

distribution transformers

49 3Ith> - ● ●

Phase discontinuity protection 46PD I2/I1> - ● ●

Negative-sequence overcurrent protection 46 I2> - - ●

Circuit breaker failure protection 50BF/50NBF 3I>BF/

Io>BF

- ● ●

Master trip 94/86 Master Trip ● ●●

Two setting groups ● ●●

Control (Function only available in REF601)

Breaker control functionality 52CB I <-> O CB ● ●●

Auto-reclosing, 4 shots 79 O -> I - - ●

Condition monitoring

Trip circuit supervision TCM TCS ● ●●

Measurement

Three-phase current measurement 3I 3I ● ●●

Residual current measurement IN Io ● ●●

Negative phase sequence current I2 I2 - - ●

Thermal level θ ϑ - ● ●

Operation counter - - - ● ●

3. Protection functions

The REF601 and REJ601 offer three-stage overcurrent and two stage ground-fault protection functions. The transformer inrush

detector function is incorporated to prevent unwanted tripping

due to energizing of transformers.

The REF601 and REJ601 offer three-stage overcurrent and

two-stage ground fault protection functions. The low-set stages

for overcurrent and ground fault protection are equipped with

selectable characteristics – Definite Time (DT) and Inverse De finite Minimum Time (IDMT). The relays feature standard IDMT

characteristics according IEC 61255-3 - Normal Inverse, Very

Inverse, Extremely Inverse, Long-time Inverse. They also feature

characteristics according to ANSI C37.112 - Moderate Inverse,

Normal Inverse, Very Inverse, and Extremely Inverse. The relays

also have a special characteristic RI Inverse (RI) for better coor dination with the rest of the network. Additionally the relays also

support two setting groups.

The REF601 and REJ601 also offer thermal overload protection

for feeders, cables and transformers. Other protections inclu de negative phase sequence protection, phase discontinuity

protection and circuit breaker failure protection. The relays also

have an auto-recloser option for overhead line feeders.

4. Application

The REF601 and REJ601 are protection relays aimed at pro tection and control of incoming and outgoing feeders in MV

distribution substations. They can be applied for short-circuit,

overcurrent and ground-fault protection of overhead lines and

cable feeders of distribution and sub-distribution networks.

The inrush current stabilization function allows the relays to be

used as the main protection for distribution transformers.

The relay with application configuration B offers non-directional

overcurrent and ground-fault protection. The residual current for

the ground-fault protection is derived from the phase currents.

When applicable, core-balance current transformers can be

used for measuring the residual current, especially when sensiti ve ground-fault protection is required.

The application configuration C adds thermal overload protec tion for feeders, cables and transformers, phase discontinuity

protection and circuit breaker failure protection.

The application configuration D provides the highest functionali ty with incorporation of negative phase sequence protection and

a multi-shot auto-recloser function making the relay suitable for

overhead line feeders.

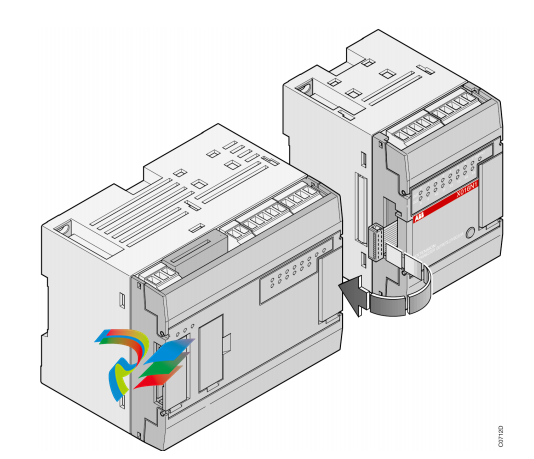

5. Optimized for limited space

With their compact size and unique technical features, the

REF601 and REJ601 are ideal for retrofits, compact switchgear

and switchgear with limited space. These relays have a small

mounting depth and do not have any loose mounting accesso ries. Uniquely, the REF601 and REJ601 use a press-fit mounting

arrangement, suitable for quick and easy installation on switch gear

6. Control

The REF601 features control of one circuit breaker with dedica ted push-buttons and guidance on local HMI for opening and

closing. It includes two dedicated outputs for breaker control.

The breaker control is also possible through optional MODBUS

RTU or IEC 60870-5-103 communication.

7. Measurement

All versions of the relay continuously measure phase currents

and ground current. Ground current can be measured using an

external zero sequence current transformer or can be calculated

internally.

During operation, the default view of display shows the highest

loaded phase current in primary terms (Amps) and the ground

current. The values measured can be accessed locally via the

user interface on the relay or remotely via the communication

interface of the relay.

These relays continuously measure negative sequence current,

thermal level and counter values if these functions are suppor ted as per application configurations.

8. Event log

To collect sequence of events (SoE) information, the relays

incorporate non-volatile memory with a storage capacity of 100

events with associated time stamps and a resolution of 1 ms.

The event log includes trip circuit monitoring status, protection

operation status, binary I/O status and relay fault code. The

event logs are stored sequentially, the most recent being first

and so on. The non-volatile memory retains its data in the event

of temporary auxiliary supply loss.

The event log facilitates detailed post-fault analysis of feeder

faults and disturbances. The SoE information can be accessed

locally via the user interface on the relay front panel or remotely

via the communication interface of the relay.

9. Recorded data

The relays store fault records of analog values for the last five

trip events in non-volatile memory. The fault recording is trigge red by the trip signal of a protection function. Each fault record

includes the current values for three phases and ground current

along with a time stamp. These records enable the user to ana lyze the five most recent power system events.

The relays record the number of phase and ground fault trip

events into dedicated trip counters. These trip counters cannot

be reset by the user and are stored in non-volatile memory.

The recorded information can be accessed locally via the user

interface on the relay front panel and can be uploaded for sub sequent fault analysis.

10. Self-supervision and test function

The relay’s built-in self-supervision system continuously mo nitors the state of the relay hardware and the operation of the

relay software. Any fault or malfunction detected will signal an

alert for the operator. A permanent relay fault will block the pro tection functions of the relay to prevent incorrect relay operati on.

The relays support a built-in test mode which enables the user

to test the relay HMI and binary outputs.

11. Trip-circuit monitoring

The trip-circuit monitoring continuously monitors the availability

and operability of the trip circuit. It provides open-circuit monito ring both when the circuit breaker is in its closed and in its open

position. It also detects loss of circuit-breaker control voltage.

12. Access control

To protect from unauthorized access and to maintain the

integrity of information, the relays are armed with a three level,

role-based user authentication system with individual pass words for operator, engineer and administrator levels. There

are two alternative password protection options. The default

is a combination of different navigation keys. The alternative is

an alpha-numeric password. The user can select the password

option based on their requirement.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923