K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

ABB UNITROL® excitation systems are a key component in many power

generating units used by plant owners and operators to achieve

reliability of operations, stability, and fast transient response of their

assets, as per grid requirements.

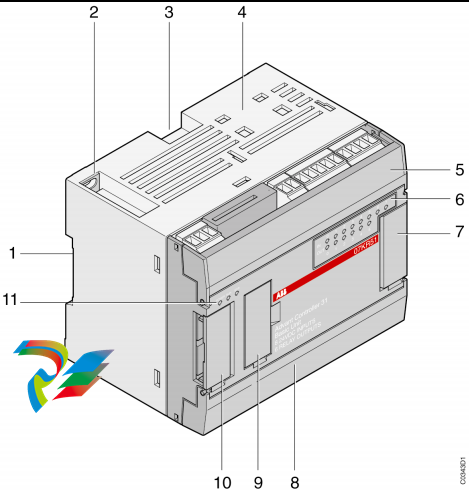

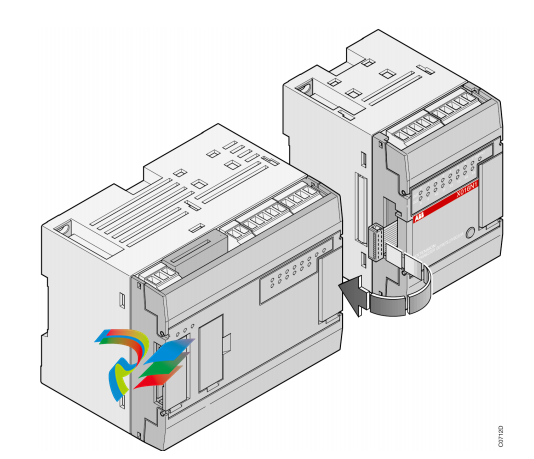

ABB UNITROL-6000 Excitation systems

UNITROL® 6000 Medium

The customizable solution

UNITROL® 6000 Medium is designed for small to medium static

excitation systems. It is as well a benchmark in flexibility, reliability

and connectivity for brushless and critical steam generating units.

With single/double channel configuration (additional

backup channel on request) and a wide selection

of thyristor bridge modules, UNITROL® 6000

Medium can be configured to meet all field data

and availability requirements.

Selected applications

• Hydro power plant

• Pumped storage power plant

• Combined cycle power plant

• Critical Steam power plant with brushless

excitation, Ifn 200 A, 400 Hz supply

Engineered solutions:

• Online supply transfer

• Electric braking

Main Features UNITROL® 6000 Medium

Customizable Yes

DC current rage <1,800 A

Backup channel Yes / Optional

Converter redundancy Single, twin, twin + backup

Max. converters 3

H configuration No

Converter types D1, D2, D3, D4, D5

PSS 2B/2C

APSS No

PEC controller generation 2

IEC 61850 Optional

Field breaker AC or DC

UNITROL® 6000 X-power

The solution for large power

applications

UNITROL® 6000 X-power is designed for large power generation units

and brings a new benchmark in flexibility, reliability and connectivity.

With single/double channel control configuration

(additional backup controller on request) and

a wide selection of thyristor bridge modules,

UNITROL® 6000 X-power can be configured to meet

all field data and availability requirements.

Selected applications

• Nuclear power plant, field current Ifn >10,000 A

• Underground hydro power plant, Ifn 4,500 A, with

redundant air-to-water heat exchanger system

• Gas turbine power plant, MEGATROL package with

Ifn 6,000 A and static frequency converter 15 MW

for turbine starting

• Coal-fired power plant, Ifn 3,500 A, power part in

IP54 container, detached AVR cabinet with >150 m

distance apart

• Hydro power plant, Ifn 4,000 A, two DC field

circuit breakers, one for DC backup excitation

Main Features UNITROL® 6000 X-power

Customizable Yes

DC current rage 1,800 A < X < 12,000 A

Backup channel Yes / Optional

Converter redundancy Single, twin, n-x

Max. converters 8

H configuration Yes

Converter types D5, UNL13300, UNL14300

PSS 2B/2C/4B

APSS Yes

PEC controller generation 3

IEC 61850 Yes

Field breaker AC (4,000) or DC

Control functions

All regulation, protection, and monitoring functions required for the

secure operation of the generator are included as standard software

features. To meet specific demands of any application, the software can

easily be configured and adapted for the requirements.

Closed-loop control

• Voltage regulator with PID filter (AUTO mode)

• Field current regulator with PI filter (MAN mode)

• Reactive and/or active current droop compensation

• Limiter circuits to ensure that the generator

operates within safe limits:

- Maximum and minimum field current

- Maximum stator current, dependent on machine

cooling media temperature

- P/Q under-excitation

- Volt/Hertz

• Manual restrict to keep the generator within safe

limits, even though controlled in manual mode

• Power factor/reactive load control

• Power system stabilizer

Protection and monitoring functions

• Monitoring and protection functions can be freely

configured on three action levels:

- Alarm signal only

- Changeover to redundant circuits

- Instantaneous excitation trip to protect the

assets

Major available functions

• Overcurrent protection (instantaneous/inverse

time)

• Volt/Hertz protection

• Loss of field protection

• Rotor temperature

• Thyristor conduction monitoring

• Actual value monitoring

Data and event recording

The internal event recorder function can handle

and store up to 2,000 events, each provided

with a real-time stamp. The data recorder contains

a preconfigured part that records a huge set of

measurements and internal signals. It is automatically triggered in case of a fault, to enable efficient troubleshooting and continuous improvement

with the aim to maximize the availability. Additional

free configurable high-speed recorders are

available to be utilized during compliance testing

or analysis of network events.

System time synchronization

The system clock of all the controllers can be

synchronized with a time source by Simple Network

Time Protocol (SNTP) with an accuracy of up to 1 ms

to allow efficient troubleshooting and align

excitation event-logs with other loggers of the

plant and minimize the time to get the unit back

on the grid.

Power system stabilizer (PSS)

The PSS function improves the stability of the

generator and the transmission system by using

the excitation to damp power oscillations.

PSS types optionally available for UNITROL® 6000:

• PSS 2A/2B/2C in accordance with IEEE standard

421.5-2016

• PSS 4B/4C in accordance with IEEE standard

421.5-2016

• Adaptive PSS (APSS) developed by ABB

Switzerland, which optimizes the PSS settings

based on the current network conditions, to

maximize availability and avoid trips due

to insufficient damping in weak networks

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923