K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Brand

Product parameters

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Description

Integrated machine terminals for the pro tection, control, measurement and supervi

sion of small and medium size generators,

synchronous motors and large asynchro nous motors.

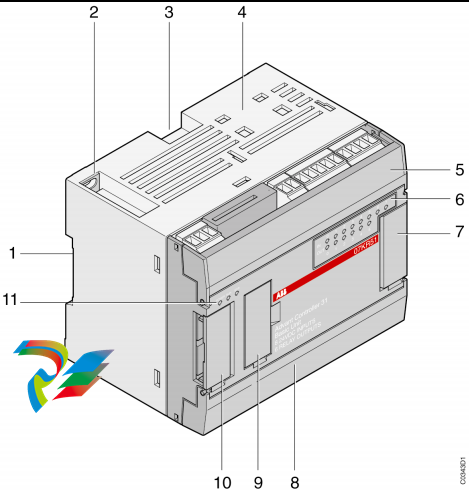

ABB REM543 Machine Terminals

Integrated machine terminals for the pro tection, control, measurement and supervi sion of small and medium size generators,

synchronous motors and large asynchro nous motors.

• Voltage and current measurement via con ventional measuring transformers or cur rent sensors and voltage dividers.

• Fixed man-machine interface including a

large graphic display, or an external display

module for flexible swichgear installation.

• Extended functionality including protec tion, control, measurement, condition moni toring and communication.

• Non-directional/directional overcur rent/earth-fault protection functions, over-

/undervoltage protection functions and spe cial functions for the protection of motors

and generators, e.g. voltage controlled

overcurrent protection, differential protec tion with several principles, underexcitation

protection, underimpedance protection

(line back-up prot.), thermal overload pro tection, protection against unbalanced

load, abnormal frequency protection,

reverse or low-forward power protection

and start-up supervision for motors.

• Control functions including local and

remote control of switching objects with

synchro-check, status indication of the

switching objects and interlockings on bay

and station level.

• Measurement of phase currents, phase-to phase and phase-to-neutral voltages, neu tral current and residual voltage, frequency,

power factor, active and reactive power

and energy.

• Optional RTD/mA I/O-module for stator

winding, bearing and ambient temperature

monitoring. Analog mA outputs for interfac ing with process control system.

• Condition monitoring including circuit breaker condition monitoring, trip circuit

supervision and internal self-supervision of

the machine terminal.

• Communication over three communication

interfaces: one for local communication

with a PC and the others for remote com munication with a substation control sys tem or with a substation monitoring system.

• Part of the ABB’s Distribution Automation

system.

Application The REM 543 and REM 545 rotating ma chine terminals are designed to be used as an

integrated main protection system of genera tor and generator-transformer units in small

and medium-power diesel, hydroelectric and

steam power plants, etc. The protection of

large and/or important MV synchronous and

asynchronous motors used e.g. in pumps,

fans, mills and crushers during start-up and

normal run forms another application area.

The REM 54_ machine terminals as inte grated packages make possible compact

marine environment solutions for unit protec tion, too.

In addition to protection, measurement, con trol and condition monitoring and general

functions, the machine terminals are provided

with a large amount of PLC functions allow ing several automation and sequence logic

functions needed for substation automation to

be integrated into one unit. The data commu nication properties include SPA bus, LON

bus or MODBUS communication with

higher-level equipment. Further, LON inter bay communication, together with PLC func tions, minimizes the need for hardwiring

between the machine terminals.

The machine terminals REM 543 and REM

545 differ from each other in the number of

digital inputs and outputs available. Please

refer to the section “Ordering” for more

details.

The REM 54_ machine terminals incorporate

a wide range of functions:

• Protection functions

• Measurement functions

• Control functions

• Condition monitoring functions

• General functions

• Communication functions

• Standard functions

The function blocks are documented on the

CD-ROM “Technical Descriptions of Func tions” (1MRS 750889-MCD).

Protection functions

Protection is one of the most important func tions of the REM 54_ machine terminal. The

protection function blocks are independent of

each other and have their own setting groups,

data recording, etc.

Typical current-based protection functions

(e.g. overcurrent) can use either Rogowski

coil or conventional current transformer mea surement. Correspondingly, voltage-based

functions (e.g. overvoltage) use either voltage

dividers or voltage transformers.

For further information about functionality

levels and the protection functions included

in them, refer to the table “Functionality lev els, protection functions” in section “Order ing”.

Measurement functions

The measurement functions include three phase currents, neutral current, three-phase

voltages, residual voltage, frequency, active

and reactive power and power factor.

An optional RTD/analogue module can be

used for measuring stator winding, bearing,

and ambient temperatures.

Disturbance recorder

The transient disturbance recorder is able to

record 16 current or voltage waveforms and

16 logic digital signals. The sampling fre quency of the analogue inputs is 2 kHz at the

rated frequency of 50 Hz and 2.4 kHz at the

rated frequency of 60 Hz.

The user can set the length of a recording

within a range determined by the number of

analogue inputs used. The number of record ings depends on the sampling frequency,

length of recordings and number of analogue

inputs.

The recordings can be uploaded with a DR Collector Tool which converts the data to a

COMTRADE format. The DR-Collector Tool

is supported in CAP501 and CAP505 relay

tools.

Control functions

The control functions are used to indicate the

status of switching devices, i.e. circuit break ers and disconnectors, and to execute open

and close commands for controllable switch ing devices of the switchgear. Furthermore,

control functions provide on/off switching

objects for control logic purposes and miscel laneous objects for data monitoring, etc.

The control functions configured with the

Relay Configuration Tool must be linked to

object status indicators included in the

MIMIC configuration picture displayed on

the HMI. The object status indicators are used

to indicate the status of switching devices via

the MIMIC picture and to control them

locally.

Condition monitoring functions

Condition monitoring function blocks such as

supervision of the energizing current and

voltage input circuit, operation time counter,

circuit-breaker electric wear, scheduled main tenance, trip circuit supervision and breaker

travel time are available for the REM 54_

machine terminals.

General functions

Additional functions are available for differ ent general purposes to be used in logics such

as activation of HMI backlight, switchgroups,

and resetting of operation indications, latched

output signals, registers and disturbance

recorder.

Communication functions

The machine terminal REM 54_ provides

three serial communication protocols: SPA,

LON and MODBUS.

Standard functions

Standard functions are used for logics such as

interlocking, alarming and control sequenc ing. The use of logic functions is not limited

and the functions can be interconnected with

protection, control, measurement, condition

monitoring and other standard functions. In

addition, digital inputs and outputs and LON

inputs and outputs can be connected to stan dard functions by using the Relay Configura tion Tool.

Other functions

Low auxiliary voltage indication

The REM 54_ terminal is provided with a

low auxiliary voltage indication feature. The

power supply module issues an internal alarm

signal when a drop in the power supply volt age is detected (ACFail, active low). The

alarm signal is activated if the power supply

voltage is about 10% below the lowest rated

DC input voltage of the power supply mod ule.

The indication of a low auxiliary voltage is

available in the machine terminal configura tion and can be connected to any signal out put of the REM54_.

Overtemperature indication

The REM 54_ machine terminal includes an

internal temperature supervision function.

The power supply module issues an internal

alarm signal when overtemperature has been

detected inside the terminal enclosure. The

alarm signal will be activated once the tem perature inside the terminal enclosure

increases to +78°C (+75°C…+83°C). Over temperature indication is available in the

machine terminal configuration and can be

connected to any signal output of the termi nal.

Analogue channels

The machine terminal measures the analogue

signals needed for protection, measuring, etc.

via sensors developed by ABB or galvani cally separated matching transformers.

Depending on whether sensors are included

or not, REM 54_ machine terminals have 9

(without sensors) or 10 (with sensors) physi cal analogue channels. The number of chan nels used depends on the machine terminal

configuration and the kind of matching trans formers or sensor inputs used. Furthermore,

the machine terminal includes virtual ana logue channels for calculating the neutral cur rent and residual voltage from phase currents

and voltages.

A current sensor (Rogowski coil) or a voltage

divider can be connected to each sensor input.

Analogue channels of the machine terminal

are configured with the CAP 505 Relay Prod uct Engineering Tool.

A separate scaling factor can be set for each

analogue channel. The factors enable differ ences between the ratings of the protected

unit and those of the measuring device (CTs,

VTs etc.). The setting value 1.00 means that

the rated value of the protected unit is exactly

the same as that of the measuring device.

• Machine terminals with the hardware

number

REM54x_xxxAAAA/CAAA/AAAB are

configured for matching transformers

• Machine terminals with the hardware

number REM54x_xxx

AABA/CABA/AABB are configured for

matching transformers and sensor inputs

Calculated analogue channels

The REM 54_ machine terminal includes vir tual channels to obtain the neutral current and

residual voltage when sensors are used. Cur rent sensors and voltage dividers are con nected to the machine terminal via coaxial

cables and therefore a residual connection of

the phase currents or an open-delta connec tion of the phase voltages cannot be made.

Both the amplitude and the phase angle are

calculated for the virtual channels.

Though primarily meant to be used with sen sors, the calculated analogue channels can

also be used with conventional current and

voltage transformers.

Note! When sensitive earth-fault protection is

needed, core balance transformers are not

recommended to be replaced with the numer ically derived sum of phase currents. Nor mally, an earth-fault setting below 10% of the

rated value requires the use of a core balance

transformer.

Digital inputs

The digital inputs of the machine terminal are

voltage-controlled and optically isolated. The

function of a digital input can be inverted.

The programmable filter time removes

debounces and short disturbances on a digital

input. The filter time is set for each digital

input of the machine terminal.

Some specific digital inputs can be pro grammed either as digital inputs or as pulse

counters. When a digital input operates as a

pulse counter, the frequency range of the

input is 0…100 Hz.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Related products

Customer Reviews

Satisfaction :

5 Stars

No evaluation information

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923