K-WANG

+086-15305925923

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Current position:

Brand

Description

Introducing the ABB HAC319AEV1: A Cutting-Edge Solution in Industrial Automation

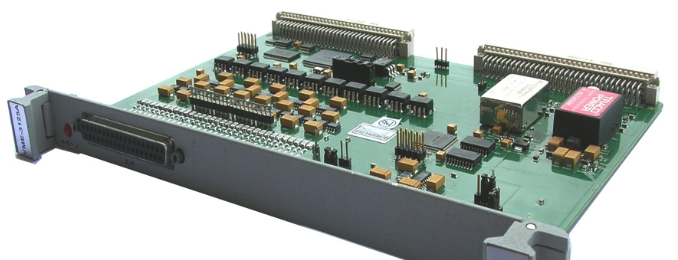

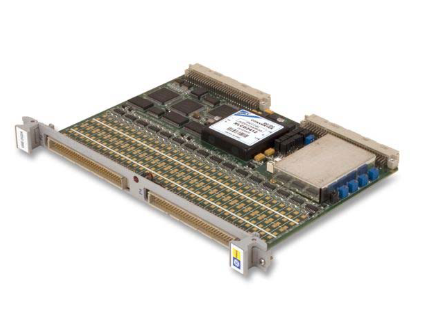

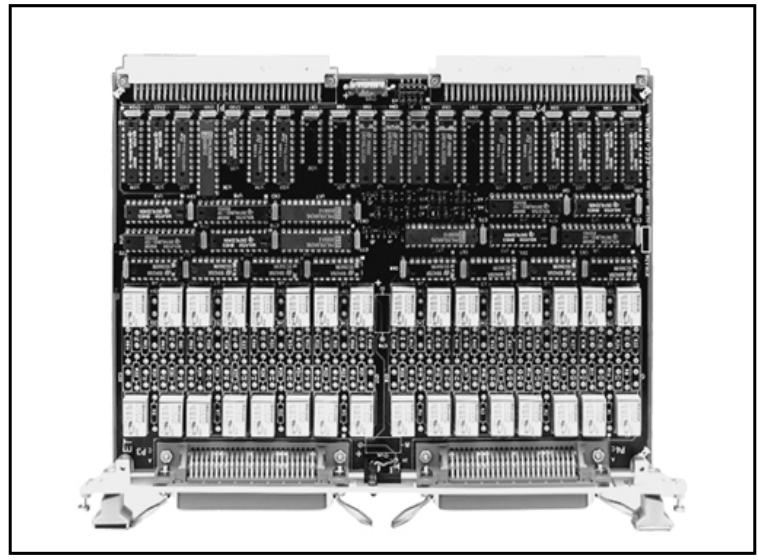

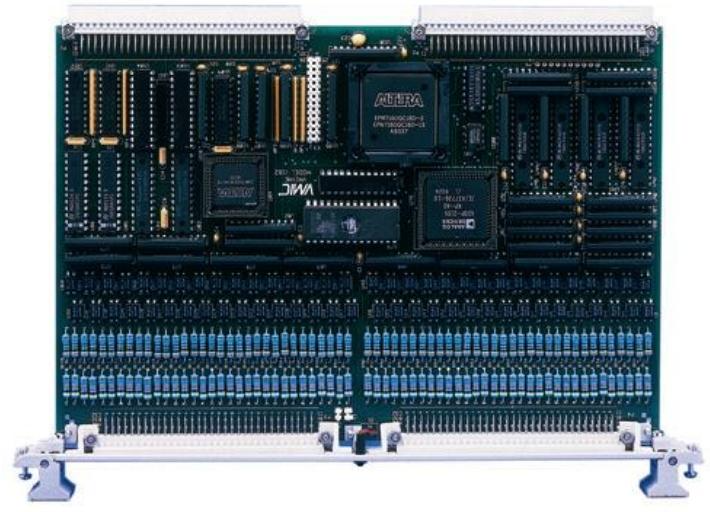

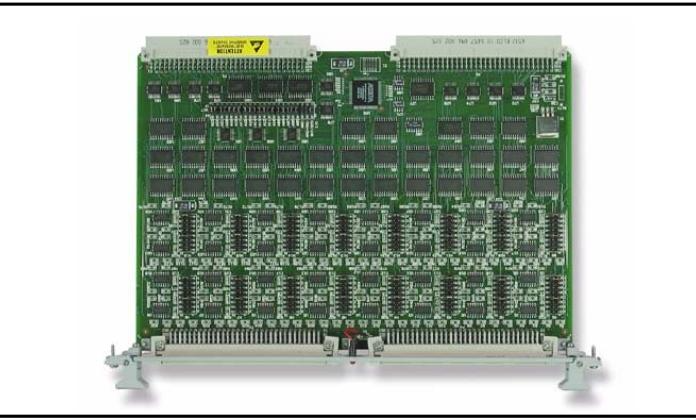

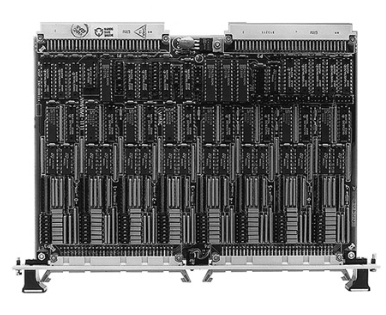

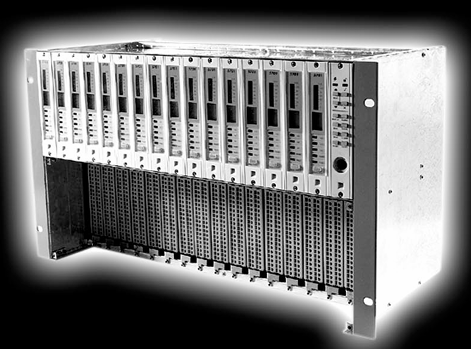

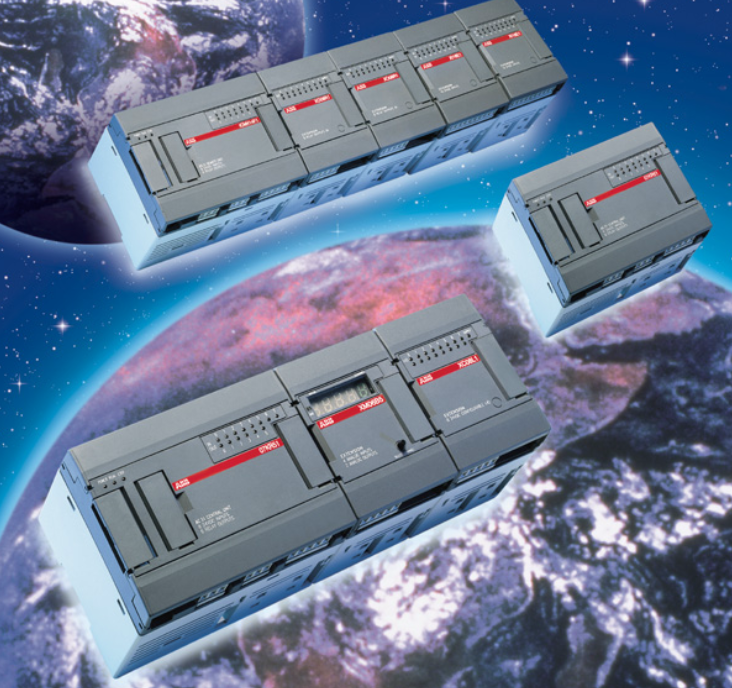

ABB HAC319AEV1 - High-Performance PLC Module for Industrial Automation

ABB HAC319AEV1 - High-Performance PLC Module for Industrial Automation

Introducing the ABB HAC319AEV1: A Cutting-Edge Solution in Industrial Automation

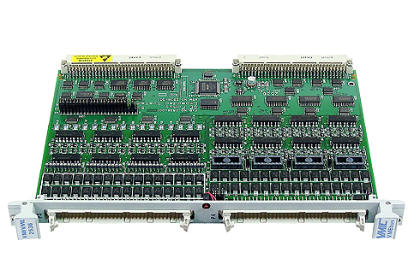

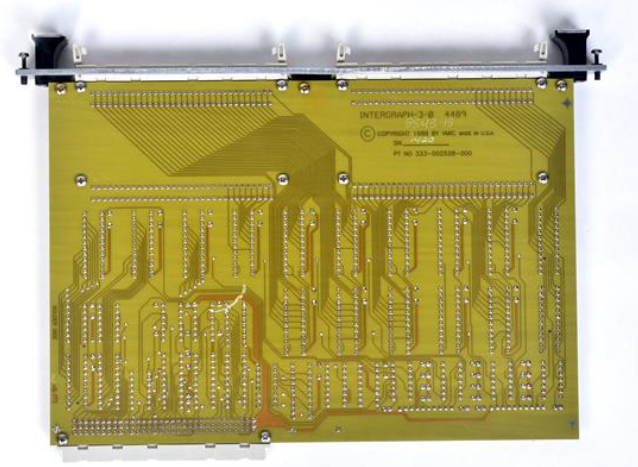

The ABB HAC319AEV1 is a state-of-the-art automation product designed to optimize performance and enhance operational efficiency in a variety of industrial applications. With its robust technical features, versatility in usage scenarios, and competitive advantages over other models in the ABB lineup, the HAC319AEV1 is a vital asset for businesses seeking to improve their automation capabilities.

Key Technical Features

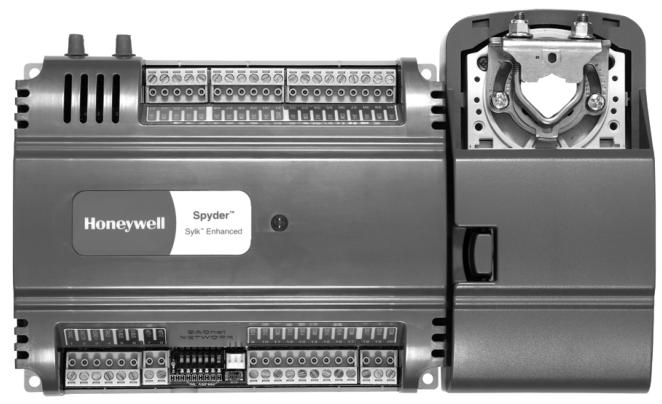

At the core of the ABB HAC319AEV1 is its advanced processing power, making it suitable for complex control tasks. This model comes equipped with a high-speed processor that ensures real-time data processing and seamless communication across networks. The HAC319AEV1 supports various industrial communication protocols, allowing for easy integration with existing systems and devices. Its compatibility with the ABB automation products ecosystem enhances its functionality and ensures that users can leverage a wide range of ABB solutions.

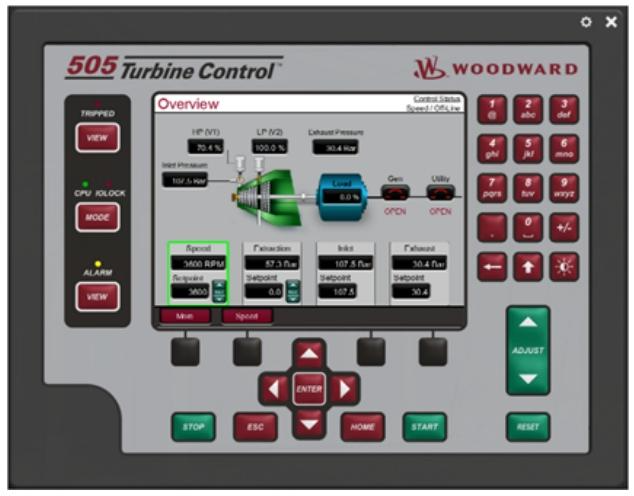

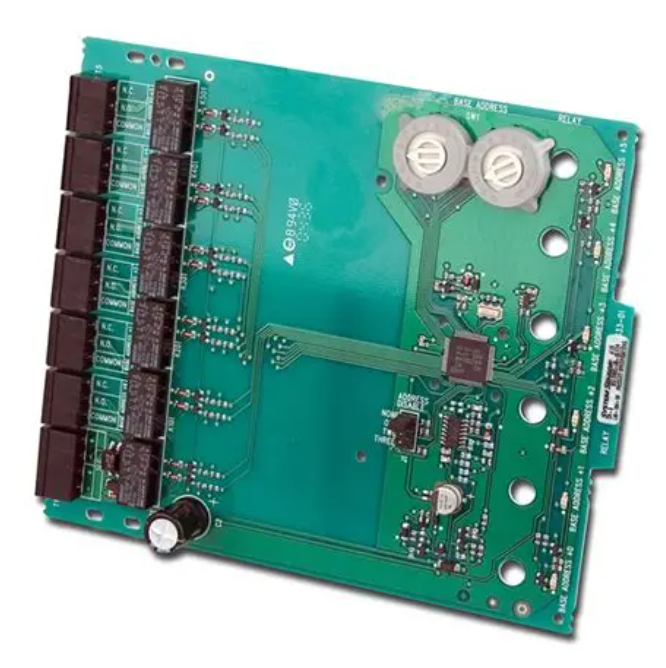

The HAC319AEV1 boasts a user-friendly interface, enabling operators to configure and monitor processes with ease. The device features an intuitive graphical user interface (GUI) that simplifies navigation and reduces training time for new users. Additionally, the HAC319AEV1 supports extensive I/O options, providing flexibility in configuring the system to meet specific application requirements.

With an operating temperature range suitable for harsh industrial environments, the ABB HAC319AEV1 is built to withstand extreme conditions. It is designed for reliability, ensuring minimal downtime and maximum productivity in critical operations. The device also incorporates advanced diagnostic capabilities, allowing for proactive maintenance and troubleshooting to further enhance operational efficiency.

Usage Scenarios

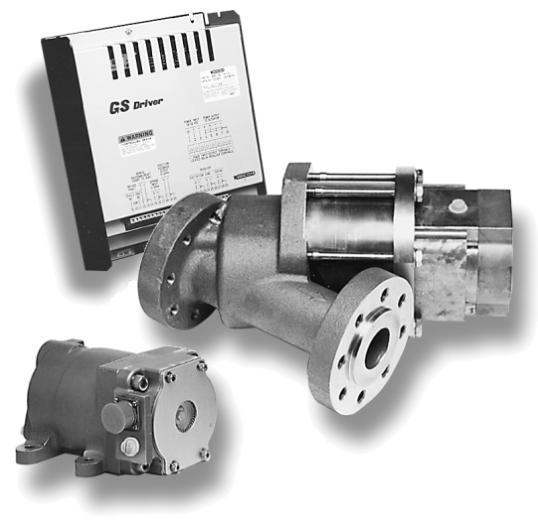

The ABB HAC319AEV1 is designed for a myriad of applications across various industries. It is particularly effective in process automation, where precise control and monitoring of machinery are essential. For example, in the oil and gas sector, the HAC319AEV1 can manage and control extraction processes, ensuring optimal performance while minimizing risks associated with equipment failure.

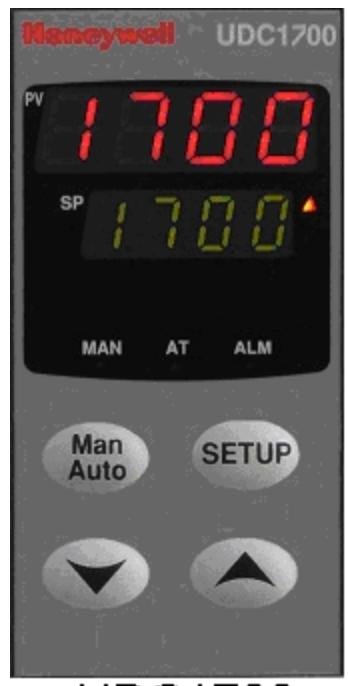

In the manufacturing realm, the HAC319AEV1 can be integrated into assembly lines to facilitate automated workflows. Its ability to communicate with other ABB automation products enables synchronization of multiple machines, streamlining production and improving overall output quality. Furthermore, the HAC319AEV1 is ideal for energy management applications, providing real-time data on energy consumption and helping organizations implement energy-saving measures.

The HAC319AEV1 also finds its application in water treatment facilities, where it can monitor and control various processes such as filtration and chemical dosing. Its adaptability and reliability make it a preferred choice for industries that demand continuous operation and high levels of precision.

Comparison with Other Models

When comparing the ABB HAC319AEV1 to other models within the ABB automation products range, several distinct advantages emerge. For instance, the HAC319AEV1 outperforms the ABB DI810 in processing speed and communication capabilities, making it a superior option for applications requiring quick response times and integration with multiple devices.

Furthermore, while the ABB 216NG63A offers basic control functions, the HAC319AEV1 excels in advanced diagnostics and remote monitoring features, providing users with enhanced insights into their operations. In contrast to the ABB PM861K01, which is limited to specific industrial environments, the HAC319AEV1’s versatility allows it to be deployed across diverse sectors, showcasing its adaptability.

The ABB UFC719AE101 presents a similar functionality but lacks the extensive I/O options available in the HAC319AEV1, making the latter a more flexible choice for complex applications. Additionally, when compared to the ABB RXIDK, known for its compact design, the HAC319AEV1 offers a more comprehensive feature set without compromising on performance.

Related Models

To provide a broader context for customers considering the ABB HAC319AEV1, it’s helpful to reference other related models within the ABB automation products family. These include:

1. ABB DI810 – A versatile input/output module known for its reliability.

2. ABB 216NG63A – A compact and efficient control solution for standard applications.

3. ABB PM861K01 – A powerful processor designed for specific automation tasks.

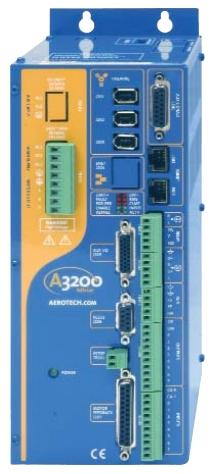

4. ABB UFC719AE101 – A reliable controller for process automation.

5. ABB RXIDK – A compact device tailored for space-constrained environments.

6. ABB CI868K01-eA – A communication interface that enhances connectivity.

7. ABB CI857K01 – A high-performance input/output module for various applications.

8. ABB PPD113B01-10-150000 – A precision control unit suitable for process management.

9. ABB DSQC202 – A robust controller for robotics and machine control.

10. ABB TA524 – A versatile actuator designed for various industrial uses.

Conclusion

The ABB HAC319AEV1 stands out as a leading choice in the realm of industrial automation, combining advanced technical features with unparalleled versatility. Its ability to integrate seamlessly with other ABB automation products makes it an indispensable tool for businesses looking to enhance productivity and streamline operations. Whether in manufacturing, energy management, or process control, the HAC319AEV1 is engineered to meet the demands of modern industrial environments, ensuring that organizations remain competitive in an ever-evolving market.

For those interested in upgrading their automation systems, the ABB HAC319AEV1 is a smart investment that promises to deliver exceptional performance and reliability. Explore the full potential of ABB's automation offerings and experience the difference that the HAC319AEV1 can make in your operations.

Purchase history

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Total 0 Record

Customer Reviews

Satisfaction :

5 Stars

No evaluation information