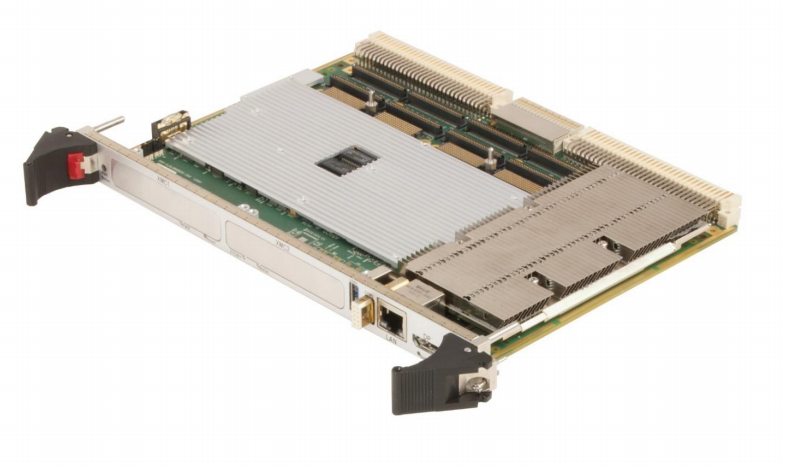

ABB HPG800 Harmony PCU Gateway

Harmony PCU Gateway (HPG800) Features■ Communicates with up to 4 AC 800M controllers

■ Communicates with other Harmony / INFI 90 controllers via Controlway and standard function codes

■ Bi-directional communication of up to 4,000 MODBUS points at 250 ms or less

■ 100 MB Ethernet port using MODBUS TCP protocol

■ Deploys adva nced RISC microprocessor technology – Motorola 32-bit Coldfire with 8 megabytes of onboard

DRAM

■ High availability and fault tolerance in a redundant pair configuration

■ Configuration supported by the Composer Engineering Tool (version 5.0, SP 2 or later)

■ Ability to interface to third-party PLC’s and devices via MODBUS TCP

Figure 21.

To learn more about the HPG800 peer-to-peer rack module, please refer to

3BUS094832.

INFI90FCLib for AC 800M. INFI90FCLib is an AC 800M evolutionary library that

contains INFI 90 Function Codes. The purpose of the INFI 90 Function Block library

is to allow Harmony system owners to protect the intellectual property embedded

within their existing controllers. Specifically, the library is designed to make

evolution of Harmony control applications to AC 800M straightforward and simple.

The INFI90FCLib does this by providing an equivalent function block in AC 800M for

the function codes from Harmony. Table 3 lists the IEC 61131-3 Function Block Types

(FBTs) provided in the INFI90FCLib.

FC# INFI 90 FC AC 800M FBT FC# INFI 90 FC AC 800M FBT

1 F(n) FnGen 97 REDDI RedDI

3 F(t) LeadLag 98 SLSEL SLSEL

4 PULPOS PulsePosn 110 RNG5 Rung5

5 PULSE PulseRate 111 RNG10 Rung10

7 SQRT Sqroot 112 RNG20 Rung20

8 VELLIM RateLimiter 116 JUMP JumpMCR

9 T XferReal 117 RECIPB RecipeBool

12 H//L HiLowComp 118 RECIPR RecipeReal

15 SUM Sum2Real 119 BMUX MuxBool

18 PID ErrPID 120 RMUX MuxReal

19 ΔPID DeltaPID 123 DD DeviceDriver

21 M/A-BAS BasicStation 124 SEQMON SeqMon

30 AOL AOL 125 DEVMON DevMon

31 TSTQ TSTQ 126 RDEMUX DMuxReal

32 TRIP TRIP 129 MSDD MSDD

34 S/R SRMem 134 MULTIMON MULTIMON

35 TD-DIG TimerBool 135 SEQMGR SEQMGR

36 QOR QOR 136 RMC RMCB

45 DOL DOL 141 SEQMST SeqMstrSlv

52 T-INT XferDint 142 SEQSLV SeqMstrSlv

58 DELAY DelayReal 151 TEXT TexSel

59 T-DIG XferBool 156 APID APID

61 BLINK Blink 160 Smith ISC

62 RCM RCM 161 SEQGEN SeqGen

65 DSUM DSum 165 MOVAVG MovAvg

68 REMSET REMSET 166 INTEGR Integrator

69 TSTALM TSTALM 167 POLY POLY

80 M/A Station 168 INPOL INPOL

81 EX/MFC Exec 171 TRIG TRIG

85 UP/DN UpDnCount 172 EXP EXP1

86 ETIMER ElapTimer 173 POWER POWER

90 EEX/MFC ExExec 174 LOG Log1

95 MODSTAT MODST 177 DAANG DAANG

96 REDAI RedAI 211 DADIG DADIG

To read more about AC 800M’s INFI 90 evolutionary library, please refer to the

INFI90 Function Code Library for AC 800M – Application Overview, 3BUS094839.

S800 I/O – Harmony Termination Unit (TU) prefabricated cables. To minimize

the risk and costs of re-terminating field wires, ABB has created a family of cables

that preserves the investments made in standard Harmony field wiring terminations.

These prefabricated cables allow for the I/O module upgrade to S800 I/O without

ever touching the field wires. The cables are used in place of the traditional NKTU

cables. They connect the existing TU to S800 I/O modules via standard cable plug-ins.

S800 I/O cables exist for 24 VDC Digital I/O, 4-20 mADC Analog I/O, TC, mV, RTD I/O

(ASM01, ASM02, and ASM03) termination units. Similar solutions exist for Harmony

Block bases (AIN, AOT, DIN, and DOT).

Whether replacing aging PLCs or incrementally upgrading older Network 90 / INFI 90

based controllers, especially AMM, LMM, COM, and MFC modules, these control evolution

products allow for seamless evolution to AC 800M – S800 I/O without the costs and risks

associated with “rip-and-replace” controller upgrade methods (summarized in Table 5).

Traditional “Rip and Replace” Upgrades ABB INFI90FCLib for AC 800M upgrades

Re-engineering or translation of control

applications

Minimal to no engineering required

New algorithms result in new process

control behaviors

Process control is same as before

Long commissioning and start-up periods

(re-configuration and re-tuning of loops)

Minimal commissioning and start-up

(no re-tuning of loops)

Create new documentation Documentation converted and enhanced

Results in:

• Greater loss of production

• Increased risk

• Higher project costs

Results in:

• Minimal loss of production

• Minimal risk

• Lower project costs

Table 5. By avoiding high project costs and production risks, ABB control evolution upgrades

cost 60 – 80% less than “rip-and-replace” alternatives

System 800xA’s Device Management features (Figure 23) lower lifecycle costs through

significant savings in the design, implementation, and operation of field equipment.

The harnessing of untapped potential from the substantial installed base of HART®

devices conforms with the ARC Advisory Group analysis that: “Users can employ many

of their HART field devices with new generation automation architectures, making the

migration to a new process automation system more economical while increasing the

availability of intelligent data that has long been under utilized.”