K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

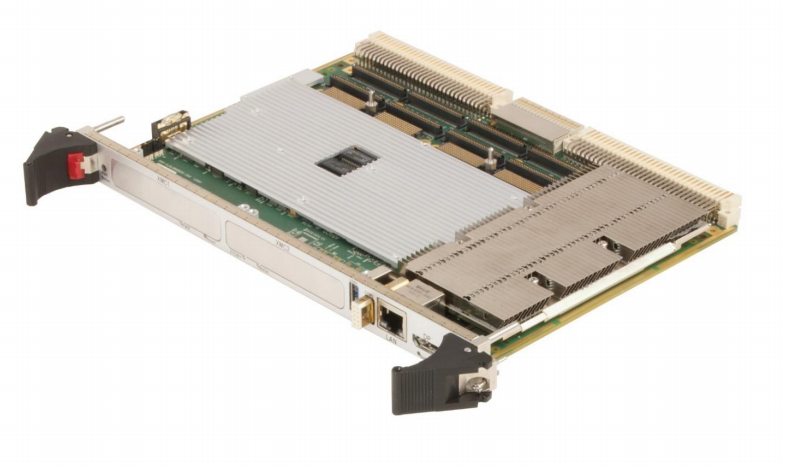

Abaco Systems’ XVR19 6U VME Single Board Computer (SBC) features the Intel Xeon quad core processor (up to 8 MByte Last Level Cache) with error checking and correction (ECC) support, integrated graphics and PCI Express (PCIe) channels. The XVR19 is also equipped with Intel’s CM238 Chipset, supporting PCIe Gen 3, allowing higher data transfer rates and more PCIe channels. The CM238 chipset also provides SATA, USB 3.0, graphic ports, SMBus, LPC and SPI design on the XVR19

Abaco XVR19 Intel Xeon Based VME Single Board Computer

1.1 Features

• Single-slot 6U VME Single Board Computer

• Intel Xeon quad core processor

• Two channels of soldered DDR4 SDRAM with ECC up to 32 GByte

• Up to 8 MByte Internal CPU shared cache

• Up to 64 GBytes of BGA NAND SSD (Optional)

• Onboard Expansion Sites (supporting either XMC or PMC)

o Site 1 (PMC rear I/O routed to P2)

▪ XMC1 – x8 PCIe

▪ PMC1 – PCI-X up to 64-bit

• 100 MHz (with option of two PMC sites)

• 133 MHz (with option of one PMC site)

o Site 2 (PMC and XMC rear I/O routed to P0) - Optional

▪ XMC2 – x4 PCIe

▪ PMC2 – PCI-X up to 64-bit / 100 MHz

• Comprehensive range of front and rear I/O features:

1.1.1 Front I/O with only One Expansion Site:

• 2x Gigabit Ethernet ports via Intel I210

• 1x DisplayPort

• 3x USB 3.0 ports

• 1x COM port

• 1x Power button

• 1 x eSATA

1.1.2 Front I/O with Two Expansions Sites:

• 1x Gigabit Ethernet port via Intel I210

• 1x DisplayPort

• 1x USB 3.0 port

• 1x COM port

• 1x Power button

1.1.3 Rear I/O via Transition Module: (Option-Dependent)

• 2x Gigabit Ethernet ports

o 1x Gigabit Ethernet via Intel I219

o 1x Gigabit Ethernet via Intel I210

• 2x Digital Video Interface (DVI-D)

• 4x SATA ports, Gen 2 capable

• 2x COM ports

• 2x USB 2.0 ports

• 8x General Purpose Input/Output (GPIO)

• 1x PMC rear I/O

• 2x Mezzio connectors (PMC/XMC)

NOTE

The VTM29 Rear Transition Module only supports the XVR19 in the environment specified for build level 1.

See level 1 details in Table A-3.

1.1.4 Other Features

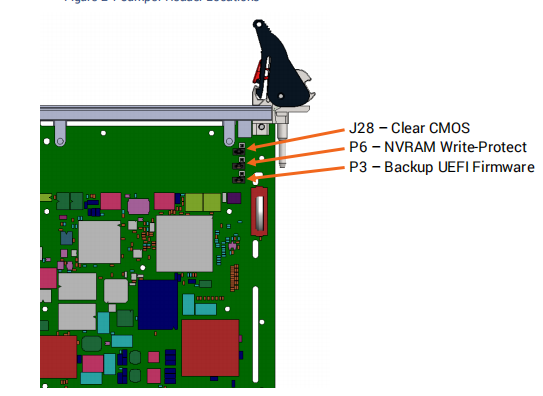

• UEFI Flash and UEFI backup Flash

• Optional extended operating temperature range

• Three levels of ruggedization

The XVR19 offers two optional onboard mezzanine expansion sites for enhanced

system flexibility, PMC- and XMC- compatible.

Memory resources include up to 32 GByte DDR4 SDRAM and up to 64 GByte

NAND Flash drive.

Software choices include comprehensive Built in Test (BIT and OS 64-bit support for

Microsoft® Windows® 10, Fedora and Redhat Linux® and VxWorks®.

1.2 Available Accessories

The following table lists the accessories that are available for the XVR19.

Table 1-1 Available Accessories

Item Purpose

VTM29 Rear Transition Module, 6U x 4HE/HP

YLB-CR12-01 10 pin har-link® to COM Port Sub-D 9 pins

adapter cable

1.3 Software Support

The XVR19 provides Intel Xeon processor with four cores with a shared memory and

I/O resource pool. Customer system applications call for software platforms that

support Symmetric Multiprocessing (SMP) operation as well as near real time

support of independent applicationthreads.

Generally, these different software needs require the support of multiple operating

systems and require software driver and Board Support Packages (BSPs) to support

the low-level hardware functions.

1.3.1 Device Driver Support

Standard Windows 10 video, chipset and network drivers used for testing during

development are available by contacting your Abaco representative. Standard

Drivers for Linux should be available from the release OS vendor. Drivers for other

specific XVR19 functions are available by purchasing the applicable OS Software

Support Package from Abaco Systems.

1.3.2 UEFI Infrastructure Support

XVR19 uses Aptio UEFI that includes all functions required by the processor core

and chipset. This package also includes the onboard hardware initialization code

that is executed following release from reset.

The UEFI also provides ROM code that supports remote booting from any of the

Ethernet ports.

1.3.3 Target Operating Systems

The XVR19 hardware supports Windows, Linux, and VxWorks operating systems.

Please contact local sales and support services for the most current operating system

version information.

NOTE

The XVR19 is shipped with Compatibility Support Module (CSM) disabled in the CMOS setup. This allows

the unit to operate in a UEFI aware environment. Some operating systems may require special drive setup

or parameters to use the UEFI mode. Contact your OS vendor for specifics needed for UEFI compatibility. If

CSM Mode is needed for Legacy OS operation, it may be enabled in the advanced CMOS setup tab. See

Section C.4.2 for CSM details.

1.4 Power Requirements

• +5V, +3.3V

• ±12V for mezzanine only

2 • Unpacking and Installation

This chapter describes the installation of the XVR19 VME Single Board Computer on

a VME backplane and initial power‐on operations.

2.1 Unpacking Procedures

On receipt of the shipping container, check for any evidence of physical damage. All

claims arising from shipping damage should be filed with the carrier and a complete

report sent to Abaco Technical Support, see Technical Support Contact Information.

Electronic assemblies use devices that are sensitive to static discharge. Observe

antistatic procedures when handling these boards. All products should be in an

antistatic plastic bag or conductive foam for storage or shipment. Work at an

approved antistatic workstation when unpacking boards.

2.2 Identifying Your Board

The board is identified by labels at strategic positions. These can be cross-checked

against the Advice Note provided with your delivery.

Identification labels attached to the shipping box and the antistatic bag give identical

information: product code, product description and equipment number. On the

board within the antistatic bag, there is an identifying label attached to the PCB.

2.3 Equipment Grounding

To minimize electric shock hazard, connect the equipment chassis and

rack/enclosure to an electrical ground. If AC power is supplied to the rack/enclosure,

the power jack and mating plug of the power cable must meet International

Electrotechnical Commission (IEC) safety standards.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923