K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

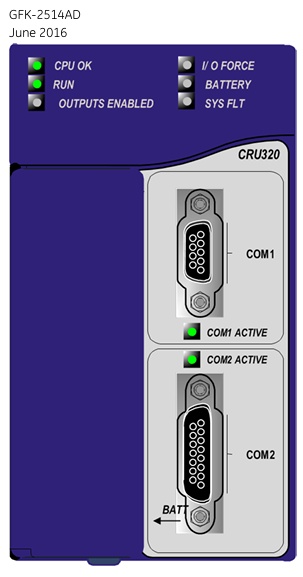

ntroduction This document contains information that is not available in any other publication; therefore, we recommend you save it for future reference. This document discusses the features of the newly released firmware version 9.00 for CPU modules IC693CPU350 and IC693CPU360

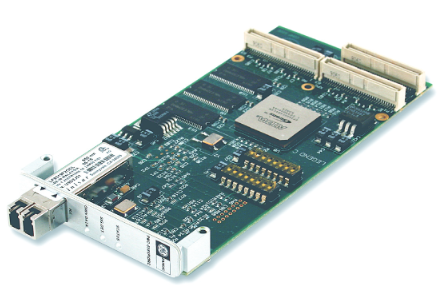

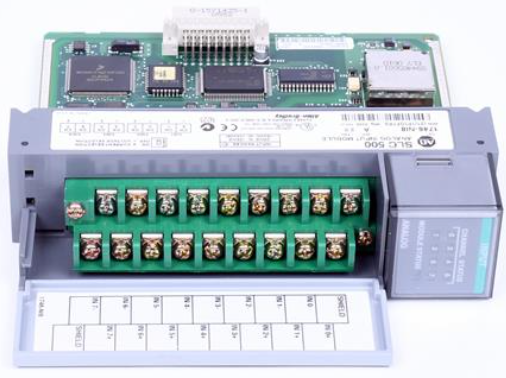

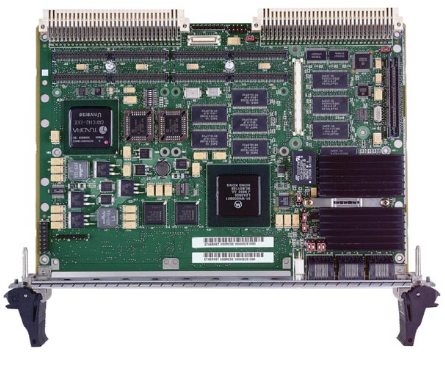

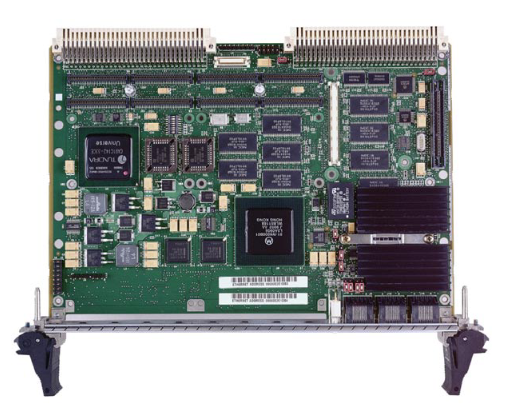

GE-IC693 CPU Modules IC693CPU350 IC693CPU360

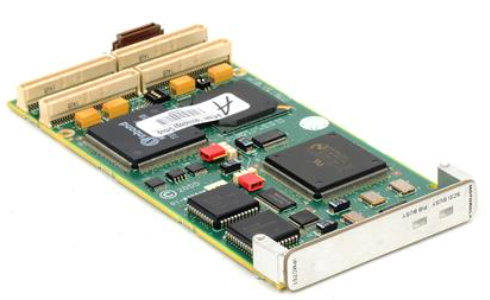

New Features and Functionality of Firmware Release 9.00 • Software Floating-Point. The CPU350 and CPU360 support all of the floating-point function blocks that are currently supported by the CPU352. They are implemented in firmware using floating point emulation. These Floating-Point math function blocks are described in the IC693 PLC Reference Manual • CPU360 user memory increased to 240K bytes. %R, %AI, and %AQ references are configurable up to 16K of %R, 8K of %AI and 8K of %AQ memory using the MS-DOS PLC programming software, version 9.02. These three references will be configurable up to 32K in the next release (version 2.2) of the Windows PLC programming software. Configuration instructions for this feature are described in the MS-DOS IC693 Programming Software User’s Manual, and will be included in on-line help in the future release of the Windows PLC Programming Software, version 2.2. Note that the CPU350 does not support configurable user memory. Its user memory is set at a fixed value of 32K bytes • Sequential Event Recorder. A new function block, the Sequential Event Recorder, is available in firmware release 9.00. This function block can be used to record up to 1024 samples of 32 individual discrete (bit) references. Both of these CPUs support this function block. Instructions on programming the Sequential Event Recorder are found in the IC693 PLC Reference Manual. Hardware Identification The following table shows the revision level of the circuit boards used in the current version of these CPUs. CPU Catalog Number Circuit Board ID Circuit Board Version IC693CPU350-** CX*A* 44A739579-G01R04 or later IC693CPU360-** CX*A* 44A739579-G01R04 or later

Firmware Upgrade Kits If you wish to upgrade an existing CPU350 or CPU360 to firmware version 9.00. you may purchase the applicable kit identified in the following table. All previous versions are capable of being upgraded. Firmware 9.00 Upgrade Kit Catalog Number CPU Catalog Number Firmware Upgrade Kit Catalog Number IC693CPU350-(all versions) 44A747145-G01 IC693CPU360-(all versions) 44A747148-G01 Firmware Identification CPU Catalog Number Motherboard Firmware Version Daughterboard Firmware Version IC693CPU350-** Main: R*.** (**A*) Boot: R*.** (**A*) N/A IC693CPU360-** Main: R*.** (**A*) Boot: R*.** (**A*) N/A Functional Compatibility * • The Windows PLC Programming Software version 2.00 or later must be used to take advantage of C programming or Sequential Function Chart (SFC) subroutines. • Version 4.00 of the C toolkit must be used for C programming. • The MS-DOS PLC Programming Software Version 9.02 or later must be used to take advantage of the new features introduced in firmware release 9.00. These new features are listed in the section “New Features and Functionality of Firmware Release 9.00Operating Notes Special Operational Notes User Flash Contents User information, consisting of program, configuration, CPU ID (used for SNP communications), and status tables in RAM memory, will automatically be cleared if the CPU firmware in flash memory is changed. So you will need to restore these if upgrading firmware. A recommended procedure is to first back up your user information from RAM memory to Flash memory. Then write your new firmware to Flash memory (firmware is stored in a different location in Flash memory than that used for storing user information such as program, configuration, etc.). Finally, write your user information back out of Flash into RAM memory. As an alternative, your user information (program, configuration, etc.) can be restored from a computer-based backup program folder using your PLC programming software. The SNP ID must be set separately, using the programming software or the Hand-Held Programmer (HHP). Firmware Upgrade Hardware Requirements Note: The Model 35x and 36x CPU operating firmware is stored in FLASH memory. The firmware upgrade is provided on a floppy disk and must be serially downloaded from a Personal Computer. An IBM AT personal computer or better PC with a minimum 640K of RAM, one 3.5” floppy drive, MS-DOS version 3.3 or later (or Windows 95 or later), a hard drive, and one RS-232 serial port is required. In addition, a serial cable is required. The following serial cable kit is available from GE Fanuc

IC690ACC901 Mini Converter Kit with cable (RS-232/RS-485) Optionally, the cable can be assembled from the following parts: IC690ACC900 RS-232 to RS-485/422 Converter Unit IC693CBL303 15 Pin RS-485 Serial Cable IC690CBL705 25 Pin RS-232 Serial Cable * IC690CBL702 9 Pin RS-232 Serial Cable * * Only one of these cables is required. Selection depends on PC Serial Port Connector. Option Module Revision Requirements • Ethernet Interface Module Compatibility. All IC693 Ethernet Interface (IC693CMM321) modules used with these CPUs should be updated to IC693CMM321 firmware release 1.10 or later. This is also a requirement of the TCP/IP Ethernet version of the MS-DOS programming software. During a Run Mode Store (Alt + S hot key combination) of a large program block (greater than 14 kilobytes), the Ethernet module may time out, causing communications to fail. Changing the Communications Window to Run-to-Completion mode, or storing the program in Stop mode, will allow the store to take place successfully. • FBC Compatibility. FBC version 3 or later is required for these CPUs. Writing to Flash Using the Windows PLC Programming Software When writing very large programs to flash memory, it may be necessary to increase the Windows PLC programming software request timeout value to avoid receiving a request timeout message. An upper bound of 25 seconds is typically satisfactory Problems Resolved in Firmware Version 9.00-11.40 Keyswitch Configured as RUN/STOP Switch Previously, when the keyswitch was configured as a RUN/STOP switch, moving the keyswitch to the STOP position would not affect the current PLC state if the PLC was already in either STOP NO/IO or STOP IO SCAN mode. In firmware version 9.00. the keyswitch will now change the PLC to STOP IO SCAN or STOP NO/IO based on the configured value, even if the PLC is already in a “STOP” mode. Storing IC693CMM321 Configuration with Windows PLC Programming Software Issue It was possible to get a watchdog time-out failure when storing an IC693CMM321 configuration with the Windows PLC Programming software, Version 2.1 or earlier. This problem has been corrected in firmware version 9.00. RET_PBLOCK_LIST The RET_PBLOCK_LIST service request would only function correctly with 24 or less subroutines in the program in firmware version 8.00. The request now functions correctly with any number of subroutines in version 9.00. Service Request #7 SVC REQ #7 would allow ladder logic to set certain illegal dates such as 2/29/01. Illegal dates are no longer allowed to be entered by the user program. Documentation Instructions for using these two modules can be found in the latest version of the following manuals: General Configuration Instructions: IC693 PLC Programming Software User’s Manual Ladder Logic Programming: IC693 PLC Reference Manual Installation Instructions: IC693 PLC Installation Manual (firmware 9.0 features will be added to revision P of this manual)

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|