K-WANG

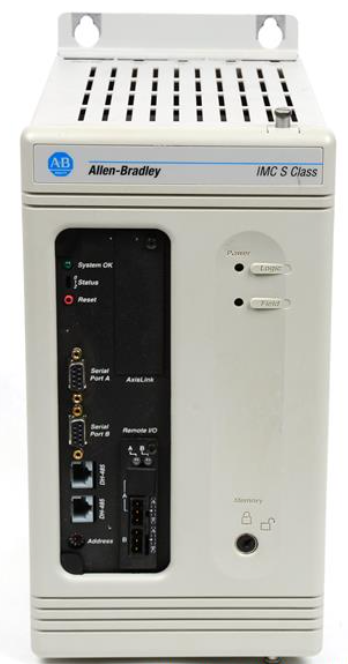

Kollmorgen QT-3832-C - Direct Drive Motor

.png)

The Kollmorgen QT-3832-C stands out as a high-performance component within Kollmorgen’s extensive portfolio of automation products, designed specifically to meet the rigorous demands of the power industry, petrochemical sectors, and general automation applications. Engineered for reliability and precision, the QT-3832-C is a versatile and robust unit that delivers superior input/output capacity, exceptional durability, and advanced performance metrics essential for modern industrial operations.

At the core of the Kollmorgen QT-3832-C’s technical prowess is its exceptional input/output handling capability. The model supports a wide voltage input range, ensuring compatibility with various industrial power sources while offering a stable and efficient output to connected devices. Its high throughput capacity enables seamless integration with complex control systems, optimizing automation processes in environments where precision and timing are critical. The QT-3832-C’s rugged construction guarantees durability under harsh operating conditions, including extreme temperatures, vibration, and exposure to contaminants commonly found in petrochemical plants and power generation facilities. This resilience is matched by its high mean time between failures (MTBF), which minimizes downtime and maintenance costs, making it a cost-effective solution for continuous operation.

Performance-wise, the QT-3832-C excels with rapid response times and low latency communication, crucial for real-time control scenarios. Its advanced internal diagnostics and fault detection features enable proactive maintenance and quick troubleshooting, reducing the risk of operational interruptions. The product also supports multiple communication protocols, allowing it to interface smoothly with existing Kollmorgen automation products such as the Kollmorgen AKD-P00606-NACN-0000 servo drive and the Kollmorgen AKM13C-ANCNR-00 motor series, enhancing system integration and scalability.

In practical applications, the Kollmorgen QT-3832-C demonstrates its strengths in power plants where precise control of turbine and generator operations is mandatory for efficiency and safety. In the petrochemical industry, it ensures reliable automation of complex fluid handling and chemical processing systems, where any failure or delay can result in costly shutdowns or hazards. Additionally, in general automation, the QT-3832-C supports manufacturing lines and robotic systems that demand high accuracy and repeatability, contributing to improved productivity and quality control.

When compared to other models in the Kollmorgen lineup, the QT-3832-C offers unique advantages that distinguish it from counterparts like the Kollmorgen PRD-B040ASIB-32 and the Kollmorgen S71202-NANANA. While the PRD-B040ASIB-32 is known for its compact design and specialized input modules, the QT-3832-C provides a broader input/output range and enhanced durability, making it more suitable for harsh industrial settings. Similarly, the S71202-NANANA excels in motion control applications but lacks the robust environmental tolerance that the QT-3832-C offers, positioning the latter as a more versatile choice for demanding automation environments.

For users seeking complementary solutions, Kollmorgen offers a wide range of compatible models. The Kollmorgen AKM64L-ACC2R-00 motor and the Kollmorgen AKD-P00306-NBAN-0000 servo drive pair naturally with the QT-3832-C to form a complete motion control system. Meanwhile, the Kollmorgen M.1016.2717 and Kollmorgen M.1016.2513 modules provide additional I/O expansion capabilities, ideal for scaling automation projects. For safety and feedback, the Kollmorgen PSR4/5A-220 sensor and the Kollmorgen INTLK-2 interlock system integrate seamlessly with the QT-3832-C, enhancing system reliability and operator safety. Additionally, Kollmorgen’s Cordset options ensure secure and durable cabling for all these components in challenging industrial environments.

The application of QT-3832-C in power industry, petrochemical, and general automation sectors is supported by its ability to adapt to varied and complex control demands. For instance, in a power generation scenario, the QT-3832-C can precisely monitor and adjust generator parameters in real time, helping maintain grid stability and efficiency. In petrochemical plants, it manages control valves, pumps, and safety systems with consistent accuracy, reducing the risk of operational hazards. For general automation, the QT-3832-C facilitates integration with robotic arms, conveyor systems, and inspection machinery, streamlining production processes and ensuring consistent output quality.

In summary, the Kollmorgen QT-3832-C is a cornerstone product in Kollmorgen automation products, combining robust construction, extensive input/output capacity, and superior performance metrics tailored for the power industry, petrochemical plants, and general automation applications. Its compatibility with a broad range of Kollmorgen models such as the AKM13C-ANCNR-00, AKD-P00606-NACN-0000, M.1016.2717, PRD-B040ASIB-32, and PSR4/5A-220 allows for highly customizable and scalable automation solutions that meet the evolving needs of industrial operations worldwide. Choosing the QT-3832-C means investing

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|