K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

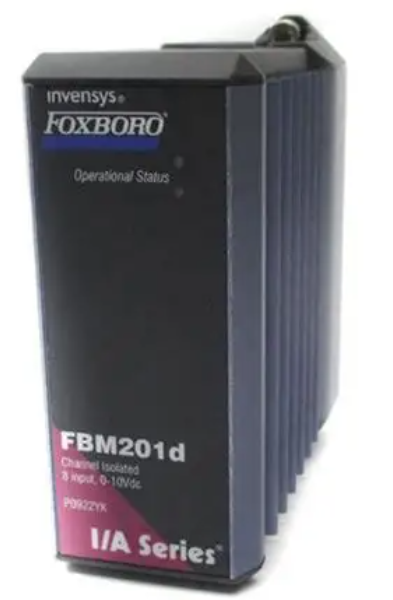

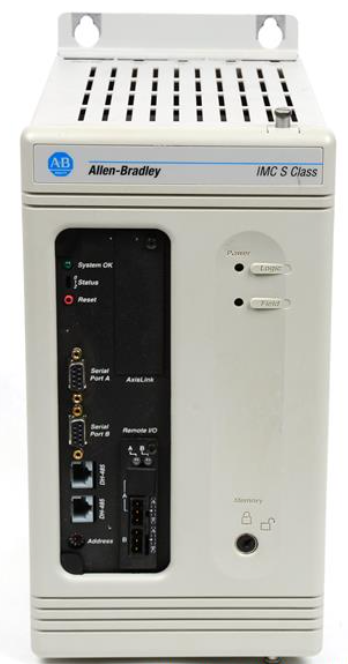

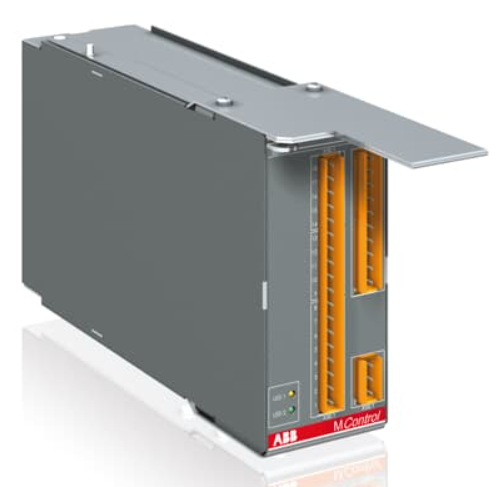

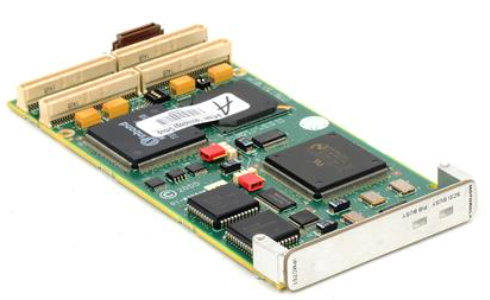

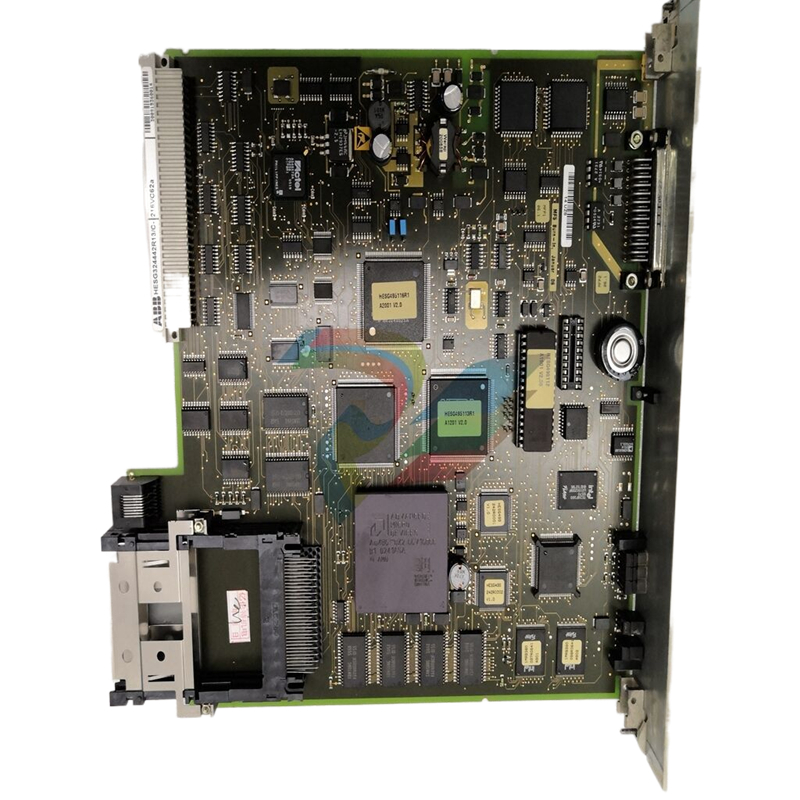

ABB SPBRC300 Symphony Plus Bridge Controller

Overview

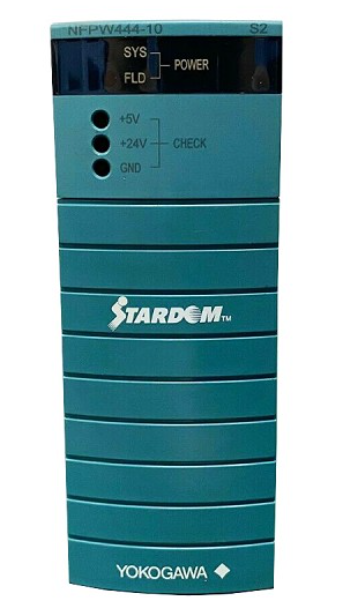

Product Description: ABB SPBRC300 is a bridge controller in Symphony Plus series, which is mainly used in industrial automation control system, playing a key role in connecting different devices and networks, realising data communication and cooperative control.

Functional characteristics: it can achieve centralised control and management of a variety of industrial equipment, support a variety of communication protocols and interfaces, with powerful data processing and computing capabilities, flexible configuration and programming to meet the specific control needs of different industrial scenarios.

Technical parameters

Processor performance: usually equipped with a high-performance processor chip, able to quickly process a large number of input and output signals and complex control logic operations, to ensure the real-time and stability of the system.

Memory capacity: a certain amount of memory for storing programme code, configuration data and temporary data during operation, etc. The size of the memory capacity affects the complexity of the tasks and the amount of data that the controller can handle.

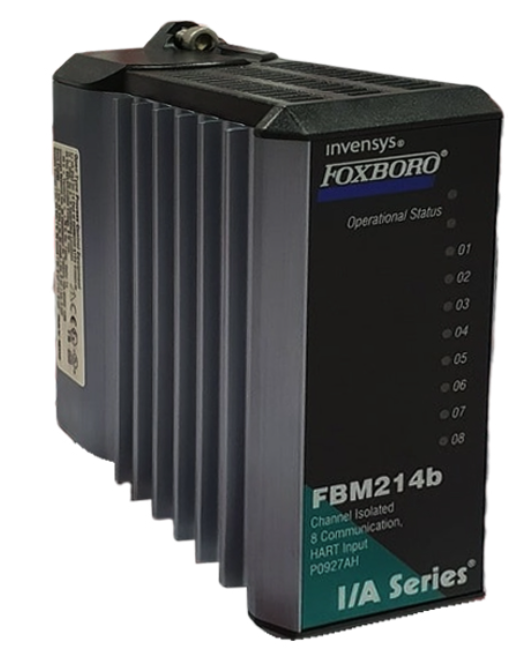

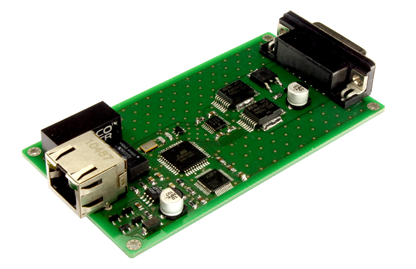

Type and number of communication interfaces: support for a variety of common industrial communication interfaces, such as Ethernet interface, Profibus interface, Modbus interface, etc., and has multiple communication ports, can be connected to a number of different types of equipment or networks, to facilitate the integration and expansion of the system.

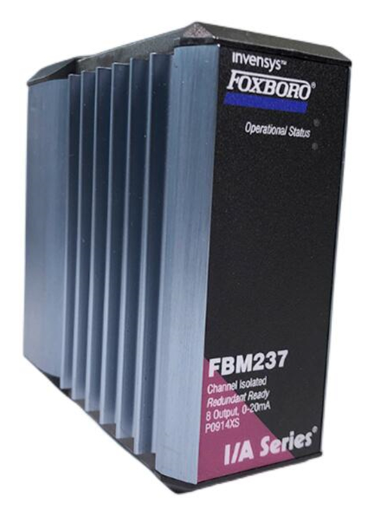

Input and output points: a certain number of digital input and output points and analogue input and output points, the specific number varies according to different models and configurations, which can meet the signal acquisition and control output requirements of industrial control systems of different scales.

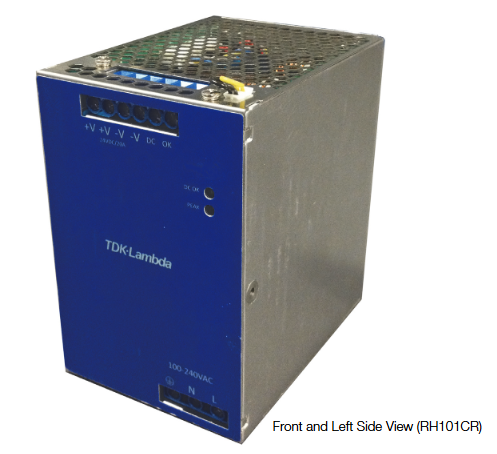

Working voltage and power consumption: the working voltage is generally adapted to a wide range, such as common 24VDC or 110VAC/220VAC, etc., with low power consumption to ensure stable and reliable operation in the industrial field, while reducing energy consumption.

Working Principle

Data acquisition and processing: through the input interface to collect signals from a variety of sensors, instruments and equipment, such as temperature, pressure, flow, level and other analogue signals, as well as switching status, fault alarms and other digital signals. The collected signals are filtered, amplified, analogue-to-digital conversion and other pre-processing, and then converted into digital signals and sent to the processor for analysis and processing.

Control logic operation: according to the pre-written control procedures and set control strategy, the input signal logic judgement, mathematical operations and data processing, to generate the corresponding control instructions. These control instructions can be on the motor, valves, pumps and other actuators, start-stop control, speed adjustment, position control, etc., can also be the parameters of other intelligent equipment settings and operating commands.

Command output and execution: the generated control commands are sent to the corresponding actuators or devices through the output interface to drive them to act in accordance with the predetermined requirements. The output signals are converted into analogue or digital signals that can directly drive the actuators after digital-analogue conversion and power amplification, thus realizing precise control of industrial processes.

Communication and network function: Using its built-in communication interface and protocol, it can communicate and interact with other controllers, operation stations, engineer stations and other devices. Remote monitoring, remote programming, fault diagnosis, data sharing and other functions can be realised, which is convenient for operators to centralise the management and maintenance of the whole industrial automation system.

Application Fields

Power industry: widely used in power plants, substations and other places, used to achieve the control of generator sets, power system monitoring and protection, substation automation control and other functions, to improve the reliability, stability and operational efficiency of the power system.

Chemical industry: In the chemical production process, it can be used to control the operation of various chemical reactors, heat exchangers, pumps, valves and other equipment, to achieve accurate control of temperature, pressure, flow, liquid level and other process parameters, to ensure the safety, stability and efficiency of chemical production.

Pharmaceutical industry: for the pharmaceutical production process of batching, mixing, reaction, filtration, drying and other aspects of equipment control and process parameter monitoring, SPBRC300 controller can provide accurate control and reliable protection to ensure the consistency and stability of the quality of drugs.

Paper industry: it can be used for speed control, tension control, pulp flow control, drying temperature control of paper machine, etc., to improve the production quality and production efficiency of paper and reduce production costs.

Metallurgical industry: In the metallurgical production process of iron and steel, non-ferrous metals, etc., it can realize the automatic control of furnace, rolling mill, crane and other equipments, as well as the monitoring and control of temperature, pressure, flow, position and other parameters in the process of production, optimize the production process, and improve the product quality and production efficiency.

Advantages and features

High reliability: the use of high-quality electronic components and advanced manufacturing process, with good anti-interference ability and stability, can be in the harsh industrial environment for a long time stable operation, reduce equipment failure and downtime, improve production efficiency.

Strong flexibility: support for a variety of communication protocols and programming methods, users can flexibly configure and customise the control functions according to the actual needs of the user to facilitate the integration of equipment and systems with different manufacturers, to achieve a variety of complex industrial process control and management.

Easy to maintain: With perfect fault diagnosis and alarm function, it can monitor the operation status of the equipment in real time, send out timely alarm information when a fault occurs, and provide detailed fault diagnosis information to help maintenance personnel to quickly locate and eliminate the fault. In addition, its modular design also facilitates the repair and replacement of equipment, reducing maintenance costs.

Good scalability: With rich communication interfaces and expandable input and output points, it is easy to add new equipment and function modules to meet the needs of continuous development and production process upgrading, and protect the user's investment.

Good compatibility: As a member of Symphony Plus series, SPBRC300 controller has good compatibility with other products of the series, which can achieve seamless integration and cooperative work, and build a powerful and stable industrial automation control system.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|