K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

This chapter provides an overview of the Helicon X3 system and a technical description of the main components that give the required knowledge about the system.The figures, drawings and text in this chapter are general and may not comply to the actual installation on the vessel. For details on the delivered equipment, see chapter 4 Delivery Specification.

Rolls-Royce Helicon X3 P&T Control System

3 Design 3.1 Lever Each thruster has its own lever. Their main functions are: • Control of pitch, RPM and azimuth direction (dependant of application) • In operation • Command transfer • Lever in command • Back-up control • Alarm The control lever has integrated buttons and indication lamps for command transfer, backup system on/off, alarm indication/buzzer and push button for reset of buzzer. The display in the base shows set command (pitch and direction) from the lever. The lever contains two redundant electronic circuits, one for the normal control system and one for the backup system

There is one command page for each thruster, in addition to one system overview page and one alarm page. The overview page shows the most essential information for all thrusters, but to activate functions or to view all available information for a thruster, the particular thrusters' page must be selected. The graphical design is based on the following principles: • All functions pages are only one click away • Large and simple buttons which are easy to read. • Same design theme for all clickable objects. • To avoid unintentional activation of functions, all function activation buttons require press on the accept button to proceed.

Indicators The indicators give feedback on various data and can be found on the bridge and in the engine control room. There are three main types of indicators: • Azimuth indicator • RPM indicator • Pitch indicator In addition a bridge order indicator may be delivered on some vessels. 3.5 Viewcon Network cabinet The network cabinet(s) contains several switches. The network cabinet(s) connects the panel PCs and the controller cabinets. Network Operator stations and electronic units are linked together in an Ethernet network. The network is single and may contain several separate switches. (CAN bus is the internal communication between levers, I/O modules and Marine Controller.)

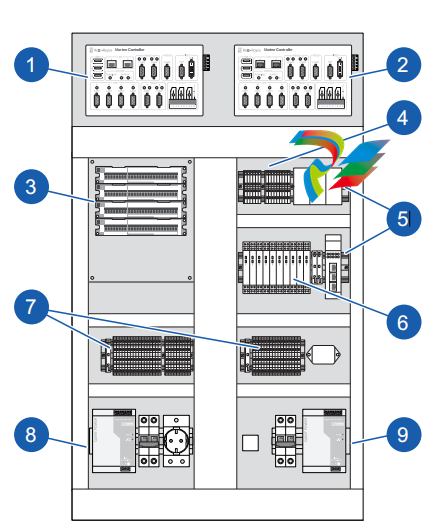

Controller cabinet Usually located on bridge or in instrument room. This cabinet distributes signals to and from the bridge and ECR. It controls all the signals from the Helicon X3 and send them to the I/O cabinet. There is one controller cabinet per propeller/thruster. Communicates with the I/O cabinet located in the thruster room. 1. Rolls-Royce Marine Controller (Normal) 2. Rolls-Royce Marine Controller (Backup) 3. I/O modules 4. Power distribution 5. Network switches and terminals 6. Signal isolation amplifiers (optional) 7. Power Distribution 8. Main power supply (AC) / fuses 9. Backup power supply (DC) / fuses 3.7 I/O Cabinet The I/O cabinet is often located in the thruster room near sensors and actuators. This cabinet distributes signals to the different propulsion/thruster units. There is one I/O unit per propeller/thruster. The I/O cabinet sends signals to the actuators on the propellers/thrusters and receives signals from the sensors. There is CAN bus communication between each I/O and controller cabinet.

1. I/O modules 2. Capacitors (optional) 3. Power distribution 4. Power distribution 5. Power / network / CANBus terminals 6. Local panel connection 7. Actuator interface card(s) (optional) 8. Relays (optional) 9. Signal isolation amplifiers (optional) 10. I/O terminals 4 Functions Tunnel Thruster Control Functions The control functions included in the Tunnel Thruster Control system: • Pitch control • Command transfer Main Propulsion Azimuth Control Functions The control functions included in the Main Propulsion Azimuth Control system: • RPM control • Azimuth control • Command transfer 4.1 Pitch Control The function of the pitch controller is to move the propeller blades in accordance to the control lever order. The actuator unit represents the interface between the remote control and the main servo system, which performs the actual positioning of the blades.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923