K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

Manufacturers

ABB

Model(s)

ABB Advant Controller 31, ABB Advant OCS

Estimated Shipping Size

Dimensions: 6.0" x 3.0" x 6.0"

(15.2 cm x 7.6 cm x 15.2 cm)

Weight: 1 lbs 2.1 oz (0.5kg )

Country of Origin: Germany

Ships from Webster NY, USA

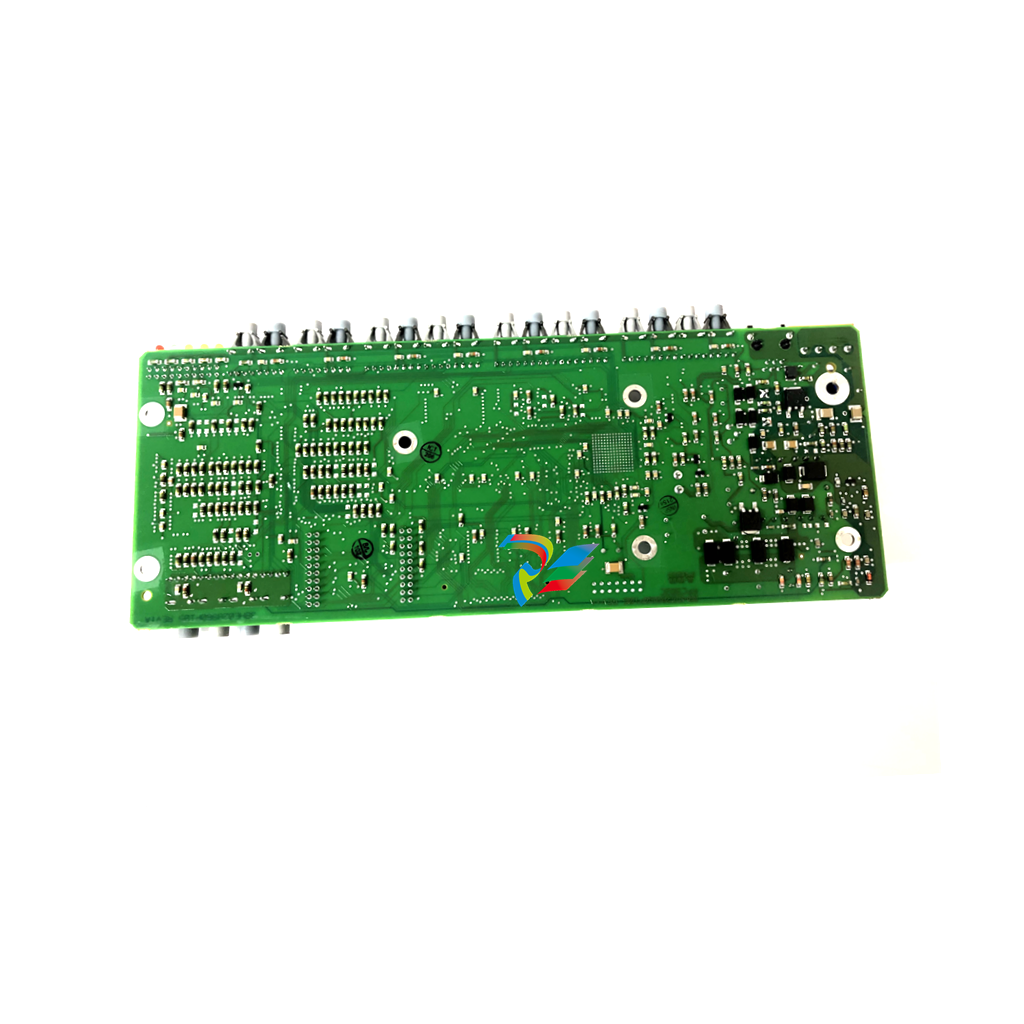

ABB GATS110091R0001 MT-40 Operator Panel

Basic information

Model identification: ABB GATS110091R0001 MT - 40 Operator Panel, where ‘GATS110091R0001’ is the specific model number of the product in the ABB product range, which is used to accurately differentiate between different configurations, versions and other details. The ‘MT - 40 Operator Panel’ indicates that this is an MT - 40 Operator Panel, which is mainly used for operating and monitoring functions in industrial automation systems.

Series: Part of ABB's GATS series, which covers a wide range of industrial automation-related products, including controllers, communication modules, HMI devices, etc. This operator panel is part of the GATS series, which includes a wide range of industrial automation-related products. As a member of this series, this operator panel can work with other products in the same series to build a complete industrial automation solution.

Size and Appearance: The screen size is usually about 4 inches, which ensures enough display area to present important information while not making the operator panel too large for easy installation and use in industrial control cabinets or operator consoles. Appearance design is usually in line with industrial aesthetics and ergonomics, with a suitable key layout (if it is a version with buttons) or touch-screen operating area for easy operator interaction.

Functional Features

Operator interface features

Information display: It is able to clearly display various important data such as equipment status, operating parameters, alarm messages and so on. For example, in an industrial automation production line, it can display real-time information such as motor rotation speed and temperature, running speed of the production line, and output. Through intuitive graphics, text and other ways of display, it is convenient for operators to quickly understand the operation of the system.

Intuitive operation: If it is an operation panel with buttons, the buttons are reasonably designed with clear function identification, which is convenient for the operator to carry out various operations, such as starting / stopping the equipment, setting and adjusting the parameters, and so on. If it is a touch screen version, it supports touch operation with good touch response, and can be operated by touch gestures for page switching, parameter input, etc., which provides a convenient way of human-computer interaction.

Customisation Functions

Interface customisation: Users can customise the operating interface according to specific application scenarios and personal preferences. For example, they can customize the displayed parameters, layout, set the display colour and font size of different parameters to highlight important information. In different industrial processes, such as chemical production and mechanical processing, users can customise the display according to the key parameters of their respective concerns.

Function customisation: It is possible to customise the operation functions, such as setting the operation rights of different users. For some key parameters, the settings can be set so that only users with advanced privileges can modify them, thus improving the security and stability of the system.

Communication Functions

Multiple communication interfaces: Equipped with a variety of communication interfaces, such as RS-232, RS-485 and Ethernet interfaces. These interfaces can be connected to various industrial devices such as PLCs (Programmable Logic Controllers), sensors, actuators, and so on. For example, the RS-485 interface can be connected to multiple field devices for centralised data acquisition and control, while the Ethernet interface facilitates communication with the host computer system or remote monitoring centre for remote operation and monitoring.

Communication protocol support: It supports common industrial communication protocols, such as Modbus RTU, Modbus TCP/IP and so on. This makes it possible to communicate with devices from different manufacturers as long as these devices support the corresponding protocols. In an industrial automation system containing multiple brands of devices, this protocol compatibility ensures that the operation panel can effectively exchange data with other devices.

Data storage and processing functions

Data Recording: With data storage function, it can record information such as operation data and operation records of the equipment. For example, it can record the equipment's fault time, fault code, parameter modification history, etc. These records are very helpful for equipment maintenance and troubleshooting. The size of the amount of data that can be stored depends on the specific product configuration, but generally able to meet the basic needs of industrial sites.

Data processing: the collected data can be simple processing, such as calculating the average value, maximum value, minimum value and other statistical data. In some process control applications, the operator can view these processed data directly through the operation panel to better understand the overall situation of the production process.

Technical Parameters

Display parameters

Screen resolution: The screen resolution generally meets the requirements for a clear display of text, graphics and data, and may be, for example, 480 x 272 pixels or a similar resolution. Such resolution can make the displayed content clear and delicate, and it is easy for the operator to view the information at different distances and angles without blurring or illegibility.

Display colour: support multiple colour display, able to distinguish different types of information by different colours, such as normal operation information displayed in green, alarm information displayed in red, etc., to enhance the visibility and recognition of information.

Performance Parameters

Processor performance: Equipped with a stable processor, its main frequency and memory capacity and other parameters can meet the basic operation and monitoring needs of industrial sites. The processor is able to respond quickly to the user's operating commands and handle a large number of data communication tasks to ensure the smoothness and real-time operation of the operation panel. For example, the main frequency of the processor may be between several hundred megahertz to several gigahertz, and the memory capacity may be between several dozen MB to several hundred MB, the specific parameters vary according to the product configuration.

Response time: has a short response time, both the response to the user's operation and data update response is more timely. For example, for the user's key operation or touch operation, can be tens of milliseconds to hundreds of milliseconds to respond to ensure the consistency of the operation; for the data update, according to the communication protocols and the state of the device in a timely manner to update the display content, so that the operator to see the information is always the latest.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923