K-WANG

- Telephone:+86-15305925923

- contacts:Mr.Wang

- Email:wang@kongjiangauto.com

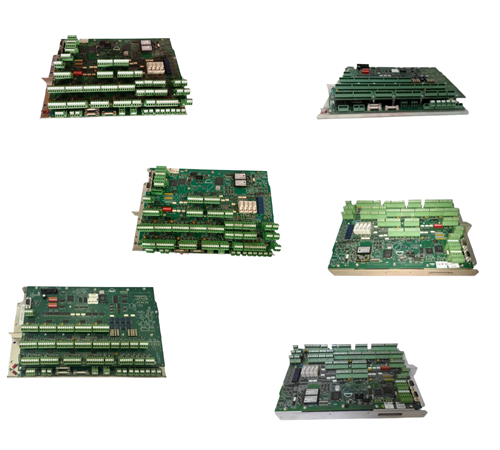

ABB PGM02 Rack PGM 02 H&B Contronic

Functional characteristics

Module mounting and combination: Standardized mounting positions and reliable mechanical and electrical connections are provided for various functional modules of H&B Contronic series. CPU modules, input/output modules, communication modules, power supply modules, etc. can be installed to realize diversified industrial automation control functions through the flexible combination of different modules.

Signal Transmission and Processing: Equipped with an efficient internal bus system, it ensures that the signals between each module can be transmitted quickly and accurately, and reduces signal interference and transmission delay, thus ensuring the stable operation of the whole control system and real-time control requirements.

System expansion and compatibility: with good expandability, new modules can be added or existing modules can be replaced conveniently according to the actual application requirements to realize the expansion and upgrading of system functions. At the same time, and the other products in this series have good compatibility, can be better integrated into the existing H&B Contronic control system.

Technical Parameters

Mechanical specifications: usually using standard industrial cabinet installation size, such as 19-inch standard rack size, easy to install in a standard industrial control cabinet. Its shell is generally made of high-strength metal materials, with good anti-vibration, anti-electromagnetic interference and other properties, can be adapted to the harsh environment of the industrial site.

Power requirements: support a variety of standard industrial power supply voltage, such as 24V DC, 110V AC or 220V AC, etc., and has a perfect power protection function, such as over-voltage, over-current, short-circuit protection, etc., can be in different power supply environment stable operation, to ensure the safety and reliability of the equipment.

Adaptability of working environment: the working temperature range is generally wide, such as - 20 ℃ to + 60 ℃, the relative humidity range is usually 5% to 95%, can work normally in most of the industrial temperature and humidity conditions, can be adapted to high temperature, humidity, dust and other harsh industrial environments.

Application Areas

Industrial automation production line: in automobile manufacturing, machining, electronic equipment production and other types of manufacturing automation production line, as the core control equipment installation carrier, to realize the automation control and monitoring of production equipment, improve production efficiency, product quality and stability of the production process.

Process industrial control system: in the chemical industry, electric power, metallurgy, pharmaceuticals and other process industries, can be installed and integrated with a variety of process control equipment and instrumentation, such as temperature sensors, pressure transmitters, flow controllers, etc., to achieve the production process of temperature, pressure, flow and other parameters of the real-time monitoring and control, to ensure that the production process is safe, stable and efficient operation.

Intelligent building automation management: In intelligent buildings, various intelligent equipments and systems such as air-conditioning control system, lighting control system, elevator control system, etc. can be installed and integrated to realize centralized management and automation control of building equipments, improve the building's energy utilization efficiency and comfort, and reduce the operation cost.

Maintenance and upkeep

Daily inspection: Regularly check the appearance of the equipment to see if there are problems such as dust accumulation, loose parts, aging connection lines, etc., clean up the dust in time, tighten the loose parts, and replace the aging connection lines to ensure the normal operation of the equipment.

Module Maintenance: Regularly check the working status of each module installed on the rack, see whether the module's indicator is normal, check whether the module's operating parameters are within the normal range through the diagnostic software or tools, and discover and deal with module failures in time.

Environmental maintenance: Keep the environment where the rack is located clean, dry and well-ventilated, avoid placing strong electromagnetic interference sources or heat generating equipment near the rack to prevent adverse effects on the rack and the equipment installed on it. At the same time, pay attention to prevent the equipment from being damaged by flooding, corrosion and so on.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923